Online prediction method for iron ore sintering bed permeability states

A technology of air permeability and material layer, which is applied in the field of online prediction of air permeability state of sintered material layer, can solve problems such as poor effect, and achieve good learning ability and generalization ability, classification method and scientific modeling idea.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and embodiments.

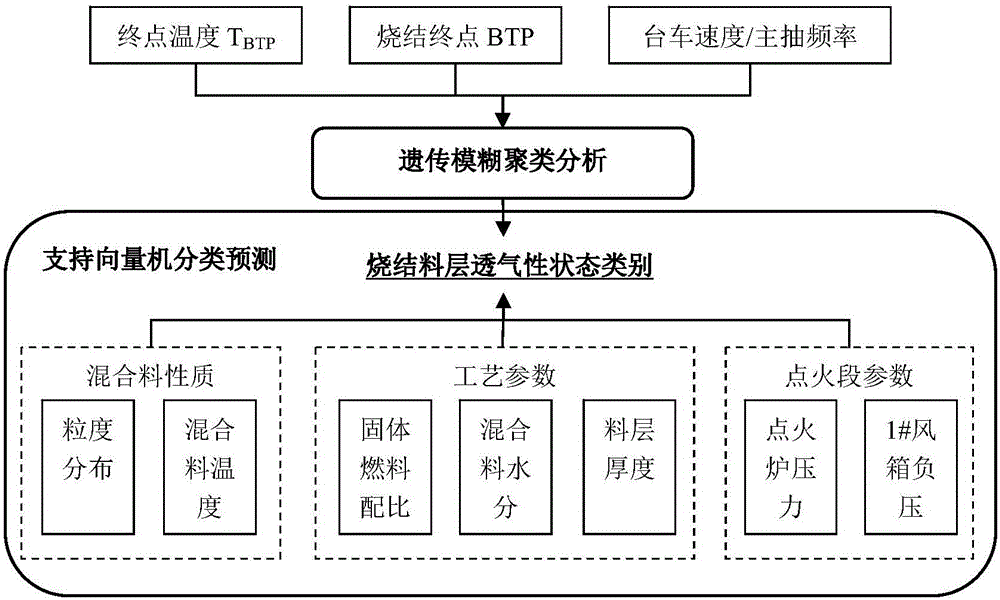

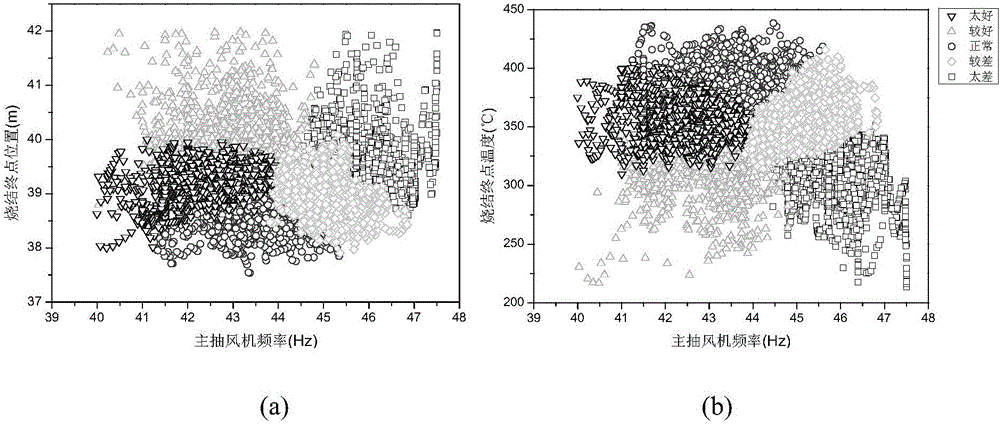

[0042] The method of the present invention adopts the state parameters and operation parameters as input, and adopts the method of cluster analysis to judge the air permeability state of the material layer; This predicts the state of the permeability of the sintered layer, and the relationship between the parameters is as follows: figure 1 shown.

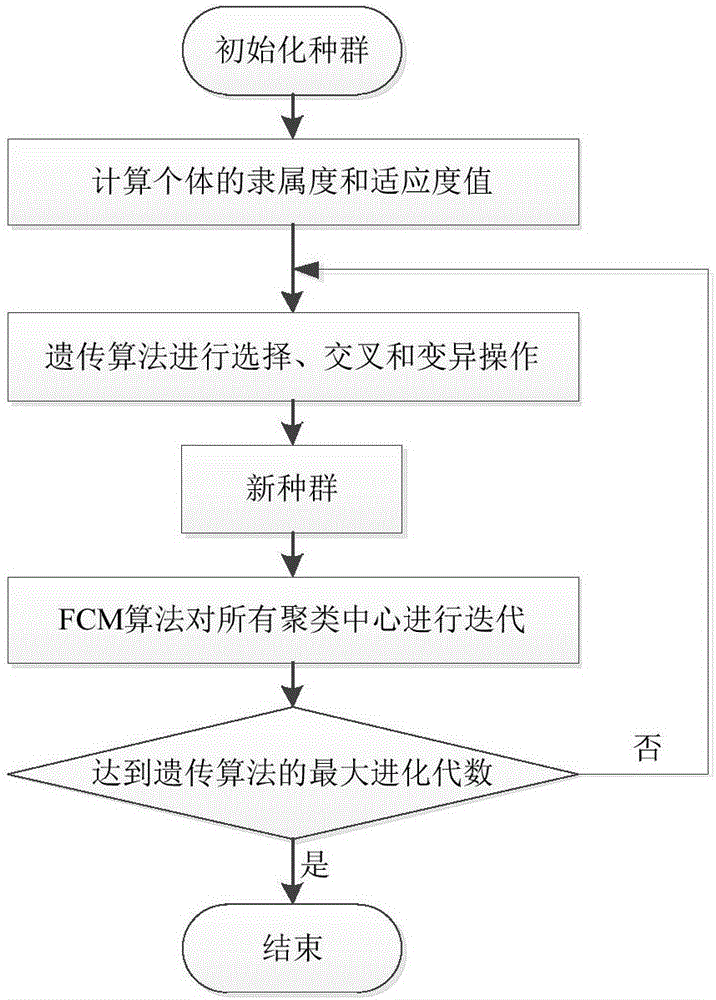

[0043] An online prediction method for the air permeability state of an iron ore sintered material layer, the specific steps are as follows:

[0044] Step 1: The production data such as the speed of the trolley or the frequency of the main exhaust fan (selected by the sintering machine using the variable frequency fan), the exhaust gas temperature of the middle and rear bellows (the fitting curve calculates the sintering end point and the end point temperature) and other production data are built into the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com