Method for charging iron ore sintering flux and device thereof

A technology for sintering flux and iron ore, which is applied in the field of iron ore sintering flux addition and flux addition devices, which can solve the problems of poor metallurgical performance, poor strength, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

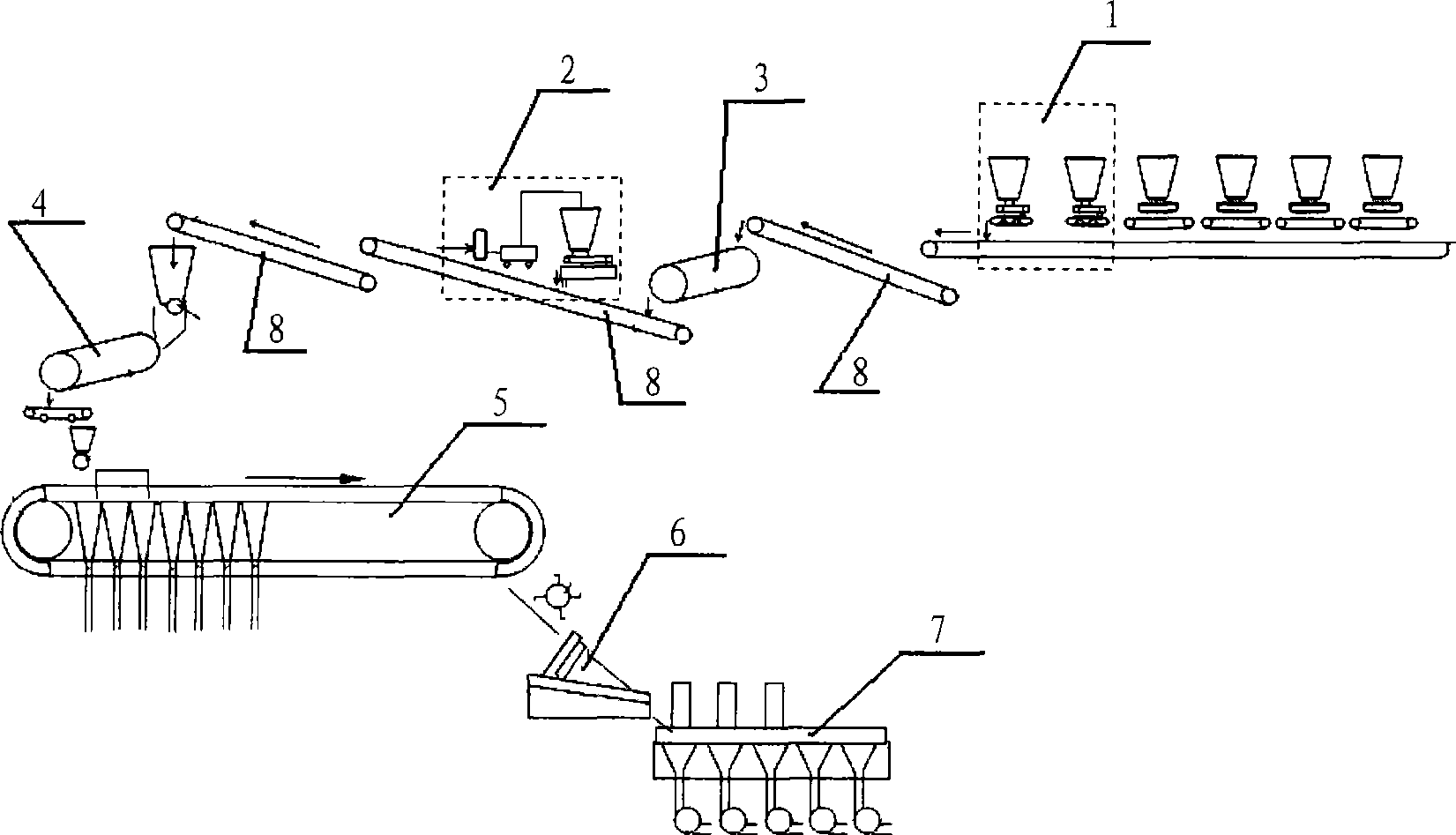

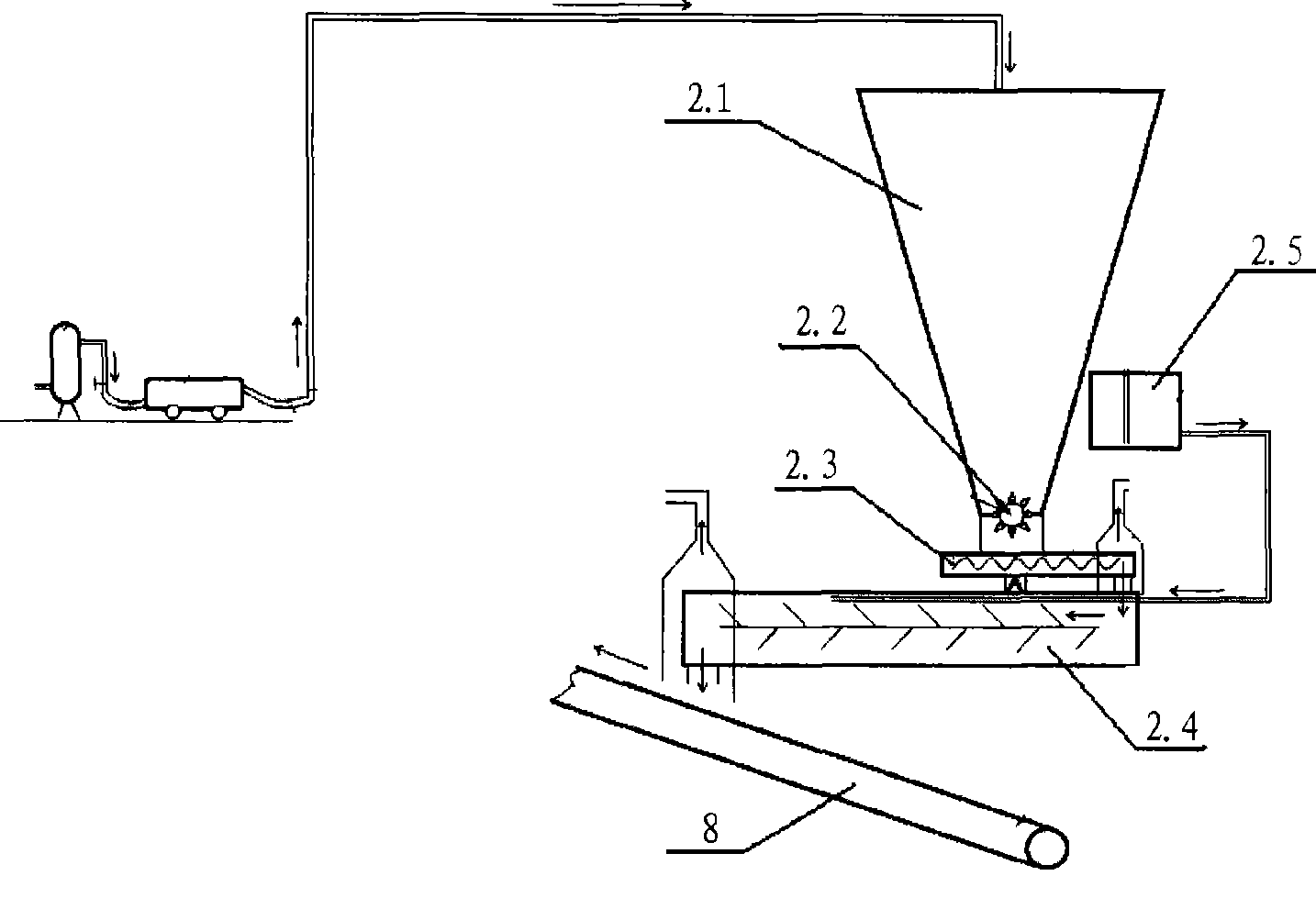

Method used

Image

Examples

Embodiment 1

[0036] In order to illustrate the principle and effect of flux addition, and to simulate the on-site flux addition method and steps, the flux addition test was carried out in the laboratory according to the above specific implementation method, and 5 batches of sinter were manufactured. See Table 1 for the ratio of raw materials and fuels used; see Table 2 for the adding method and ratio of flux. %; See Table 3 for technical and economic indicators of sinter.

[0037] Experimental process parameter control: the moisture of the mixture is 6.5-7.5%, the material layer is 600-670mm, the ignition temperature is 950-1150°C, the sintering negative pressure is 11000Pa-12500Pa, and the exhaust gas temperature is 100-130°C.

[0038] Table 1 The proportion of raw materials in each batch of laboratory flux distribution test (%)

[0039]

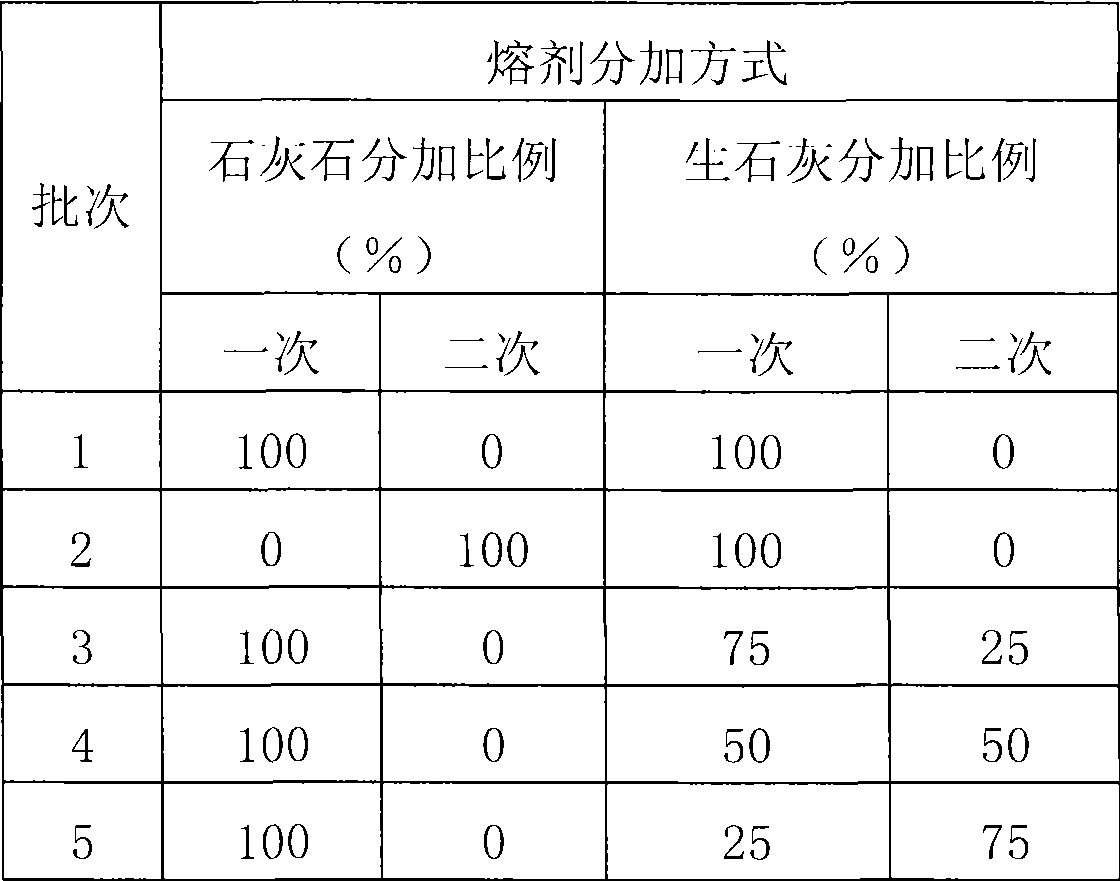

[0040] Table 2 Addition method and proportion of each batch of laboratory flux addition test

[0041]

[0042] Table 3 Technical effect of...

Embodiment 2

[0046] According to the iron ore sintering flux distribution method and steps of the present invention described according to the specific implementation mode, embodiment 2 is at 173.6m 2 The flux distribution device of the present invention was used on the sintering machine to produce 4 batches of sintered ore. In terms of weight percentage, the ratio of raw materials and fuels is shown in Table 4.

[0047] Table 4 Ratio of quicklime secondary separation plus raw material and fuel

[0048] (Explanation: The total ratio in actual production is not strictly 100%, but close to 100%)

[0049]

[0050] See Table 5 for the adding method and ratio of flux.

[0051] Table 5 Ratio and proportion of quicklime secondary addition

[0052]

[0053] The test results of Example 2 are shown in Table 6.

[0054] Table 6 Comparison of technical effects of quicklime secondary addition and non-addition

[0055]

[0056] It can be seen from Table 6 that compared with the sintering r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com