Method for improving strength and size composition of sinter

A technology of particle size composition and sintering, which is applied in the field of metallurgy, can solve the problems of sintering energy waste, increased powder return rate, and increased shipping costs, and achieve the effects of reduced solid fuel consumption, improved particle size composition, and increased drum strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

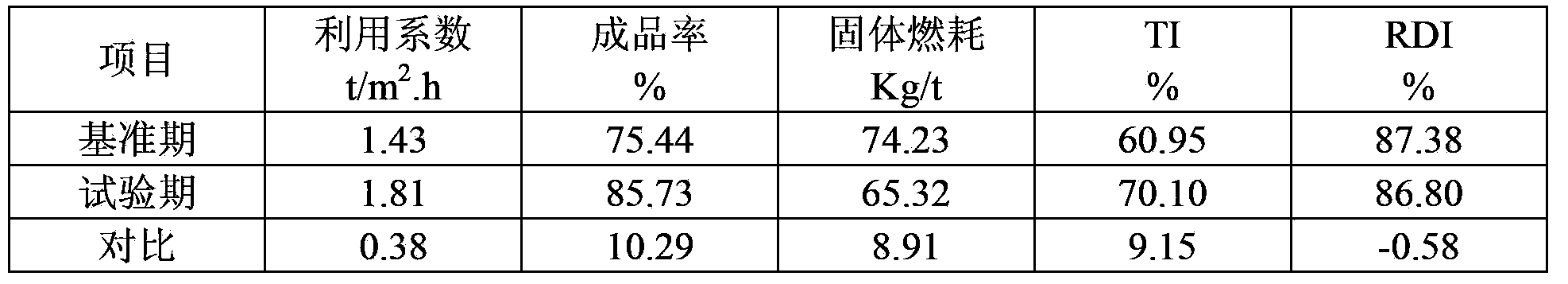

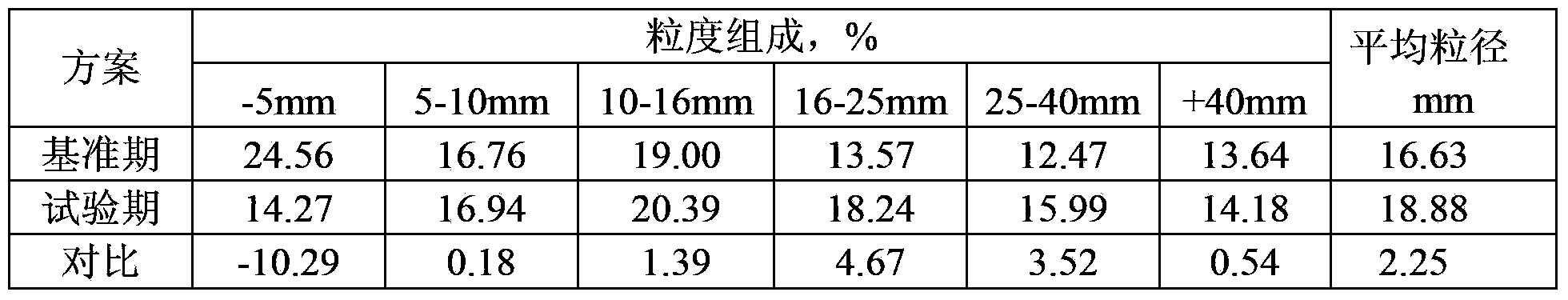

Examples

Embodiment 1

[0012] Embodiment 1 (the basicity value of sintered ore is CaO / SiO 2 for 1.8-2.0)

[0013] (1) Various iron ore powders: 6% rocket super powder, 10% Mauritania powder, 20% Canadian fine powder, 10% Brazilian high silicon powder, 30% Sierra Leone coarse powder, 2% recycled iron fine powder and sintered Mineral powder 22% is prepared in the pre-batching room of the raw material yard to make neutralizing material, and it is laid flat in the secondary material yard to build a pile. After the pile is closed, it is intercepted in the neutralizing material pile by a stacker-reclaimer, and transported to the sintering batching room through a belt;

[0014] (2) In the batching room, mix the neutralization material, coke powder, brucite fiber, calcium flux, and magnesium flux (see the test period in Table 1 for the specific ratio); add brucite fiber (SiO 2 34wt%, MgO23wt%, CaO22%), use electric vibration feeder to feed to ensure the accuracy of feeding;

[0015] Table 1 Sintering raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com