Method for preventing deliquescence and pulverization of lime by using nitrogen

A technology of lime powder and lime, which is applied in the field of metallurgy and can solve the problems of lime being affected by moisture, consumption, and large electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

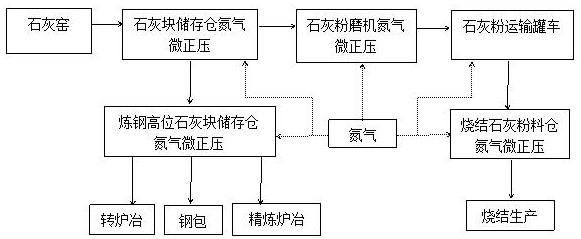

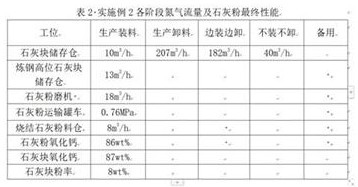

[0071] Nitrogen is used to isolate the lime from the air under a slight positive pressure (to form a nitrogen micro-positive pressure environment around the lime, thereby isolating the contact between the lime and the humid air) to prevent the lime from absorbing moisture and decomposing. The nitrogen in the lime block storage bin is charged The flow rate is 5m 3 / h, the nitrogen flow rate during production and unloading is 197m 3 / h, the nitrogen flow rate when loading and unloading is 172m 3 / h, the nitrogen flow rate when not loading or unloading is 30m 3 / h; Steelmaking high-level lime block storage bin is filled with nitrogen gas for 15m 3 / h, so that it can obtain a slight positive pressure of nitrogen; the lime pulverizer is filled with nitrogen for 20m 3 / h, so that it can obtain a slight positive pressure of nitrogen; the nitrogen pressure for lime powder transportation tank truck ashing is 0.8MPa, and the sintered lime powder silo is filled with nitrogen for 10m ...

Embodiment 2

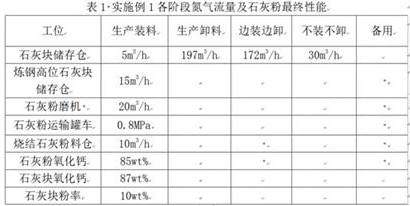

[0074] Nitrogen is used to isolate the lime from the air under a slight positive pressure to prevent the lime from absorbing moisture and decomposing. The nitrogen flow rate of the lime block storage bin when loading is 10m 3 / h, the nitrogen flow rate during production and unloading is 207m 3 / h, the nitrogen flow rate when loading and unloading is 182m 3 / h, the nitrogen flow rate when not loading or unloading is 40m 3 / h; Steelmaking high-level lime block storage bin is filled with nitrogen for 13m 3 / h, so that it can obtain a slight positive pressure of nitrogen; the lime pulverizer is filled with nitrogen for 18m 3 / h, so that it can obtain a slight positive pressure of nitrogen; the nitrogen pressure used for lime powder transport tank truck ashing is 0.76MPa, and the sintered lime powder silo is filled with nitrogen 8m 3 / h, so that it can obtain a slight positive pressure of nitrogen. The calcium oxide detection of the final lime powder was 86wt%, the calcium oxid...

Embodiment 3

[0077] Nitrogen is used to isolate the lime from the air under a slight positive pressure to prevent the lime from absorbing moisture and decomposing. The nitrogen flow rate of the lime block storage bin is 15m when charging. 3 / h, the nitrogen flow rate during production and unloading is 202m 3 / h, the nitrogen flow rate when loading and unloading is 179m 3 / h, the nitrogen flow rate when not loading or unloading is 35m 3 / h; Steelmaking high-level lime block storage bin is filled with nitrogen gas for 10m 3 / h, so that it can obtain a slight positive pressure of nitrogen; the lime pulverizer is filled with nitrogen for 15m 3 / h, so that it can obtain a slight positive pressure of nitrogen; the nitrogen pressure for lime powder transportation tank truck ashing is 0.7MPa, and the sintered lime powder silo is filled with nitrogen for 5m 3 / h, so that it can obtain a slight positive pressure of nitrogen. The calcium oxide detection of the final lime powder was 87wt%, the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com