Method for reducing NOx emission in iron ore sintering process

A sintering process, iron ore technology, applied in fuel additives, petroleum industry, fuel, etc., can solve the problems of high additive consumption and low emission reduction, and achieve the effect of reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

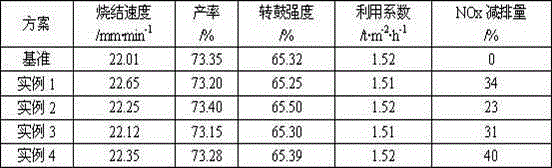

Examples

Embodiment 1

[0025] A method for reducing NOx emissions in the iron ore sintering process of the present invention comprises sieving the coke powder used for iron ore sintering into three grades of -1mm, 1-3mm and +3mm. Mix -1mm coke powder, straw charcoal and asphalt with a particle size of -1mm at a mass fraction of 75%, 18%, and 7% respectively, and then press it under a pressure of 1.5MPa to form a mixture with a particle size of 1-3mm. fuel particles. Add the prepared 1-3mm mixed fuel particles and 1-3mm coke powder to fine-grained iron ore (average particle diameter ≤ -2mm), part of coarse-grained iron ore (average particle diameter>-2mm), flux and In the process of returning to the ore, the alkalinity of the mixed material is 2.0 by controlling the proportion of the coarse-grained grade, and then the mixed material is granulated once in a cylinder mixer, and the granulation time is 4 minutes. The mixed material that has been granulated once and the modified +3mm coke powder (add 10...

Embodiment 2

[0027]A method for reducing NOx emissions in the iron ore sintering process of the present invention comprises sieving coke powder for iron ore sintering into three different particle sizes of -1mm, 1-3mm and +3mm. Firstly mix -1mm coke powder with -1mm semi-coke and asphalt according to the mass fraction of 80%:15%:5%, and then press it under the pressure of 2.5MPa to form a particle size of 1-3mm. Mix fuel pellets. Add the prepared 1-3mm mixed fuel particles and 1-3mm coke powder to fine-grained iron ore (average particle size≤-2mm), part of coarse-grained iron ore (average particle size>-2mm), flux and In the process of returning to the ore, the alkalinity of the mixed material is 2.2 by controlling the addition ratio of the coarse-grained grade, and then the mixed material is granulated once in a cylinder mixer, and the granulation time is 4.5 minutes. The mixed material that has been granulated once, the modified +3mm coke powder (+3mm coke powder is added with slaked li...

Embodiment 3

[0029] A method for reducing NOx emissions in the iron ore sintering process of the present invention comprises sieving coke powder for iron ore sintering into three different particle sizes of -1mm, 1-3mm and +3mm. Firstly mix -1mm coke powder with -1mm fat coal and asphalt according to the mass fraction of 75%:17%:8%, and then press it under the pressure of 1.5MPa to form a particle size of 1-3mm. Mix fuel pellets. Add the prepared 1-3mm mixed fuel particles and sieved 1-3mm coke powder to fine-grained iron ore (average particle diameter≤-2mm), part of coarse-grained iron ore (average particle diameter>-2mm ), flux and return ore, the basicity of the mixture is 2.2 by controlling the proportion of coarse-grained grades, and then the mixture is granulated once in a cylinder mixer, and the granulation time is 5 minutes. The mixed material that has been granulated once, the modified +3mm coke powder (+3mm coke powder is added with slaked lime with a mass fraction of 15%, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com