Automatically identifying and quantitatively detecting method for high alkalinity sintered ore main minerals

A technology for automatic identification and sintering, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as uncertain crystal structure parameters of solid solution minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

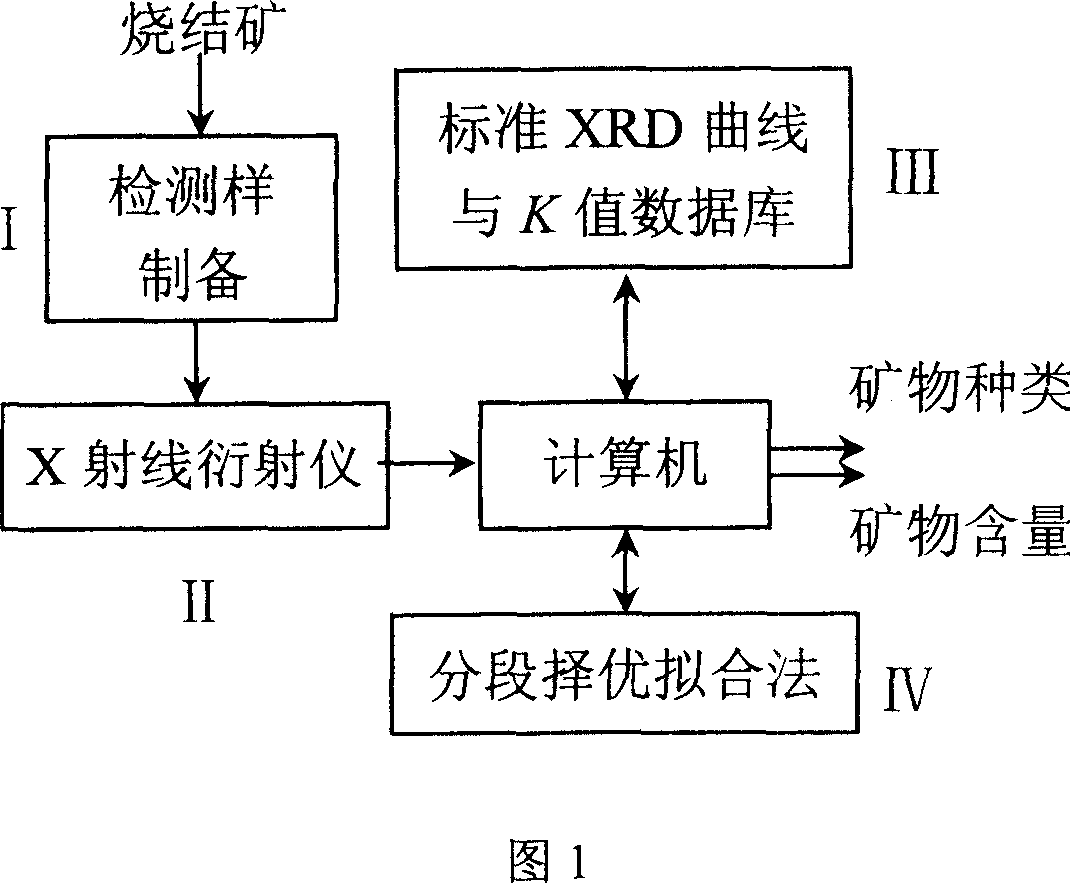

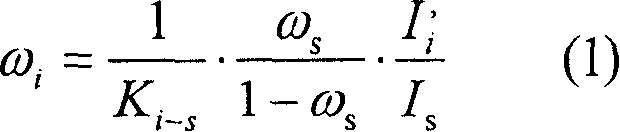

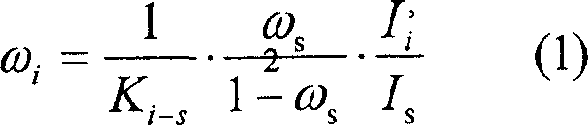

Method used

Image

Examples

example 1

[0015] Example 1: The prepared hematite, magnetite and quaternary calcium ferrite (Ca 5 Si 2 Fe 16 Al 2 o 36 , simplified into cf(4)) minerals, ground to a particle size of less than 0.050mm, adding 10% TiO 2 As a reference substance, the different proportions are shown in Table 1 and mixed thoroughly. Then, X-ray diffraction was performed on the mixed sample in the range of 15-65° at a scanning speed of 2° / min on an M21X X-ray diffractometer. Open the X-ray diffraction quantitative analysis software, then select qualitative analysis, give the possible mineral types and corresponding error indexes, and the minerals corresponding to each diffraction peak, finally, determine the type of reference material, perform quantitative calculation and give The calculated results show that the absolute error is within ±1.80%.

[0016] Experiment number

example 2

[0018] The high-alkalinity sintered ore of Baosteel in May 2005 was subjected to quantitative analysis by X-ray diffraction. Its chemical composition is shown in Table 2. Through peak comparison and diffraction analysis, it can be seen that the minerals in the sintered ore include hematite and magnetite. ore and calcium ferrite. Using this method to carry out mineral quantitative analysis results, the three contents are 54.91%, 19.24% and 25.83% respectively.

[0019] time

[0020] The mineral detection of each sample above, from the beginning of the diffraction experiment on the X-ray diffractometer to the qualitative and quantitative process on the computer, was completed within 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com