Method for biomass carbonization instead of pulverized coal injection in blast furnace

A technology of biomass charcoal and pulverized coal injection, applied in blast furnaces, biofuels, blast furnace details, etc., can solve problems such as the lack of high-quality coal resources and the difficulty of using poor coal resources, so as to reduce the amount of flux and reduce the amount of blast furnace slag , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

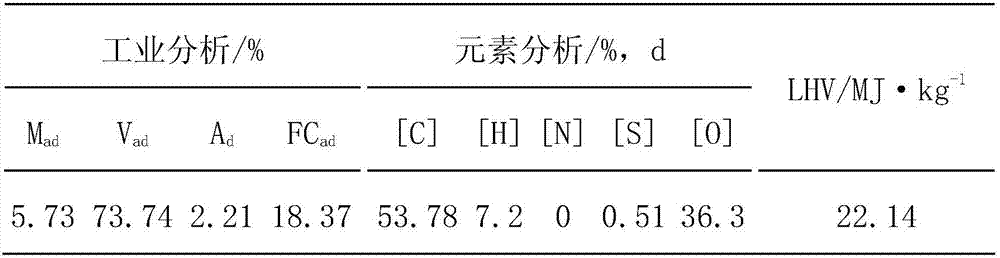

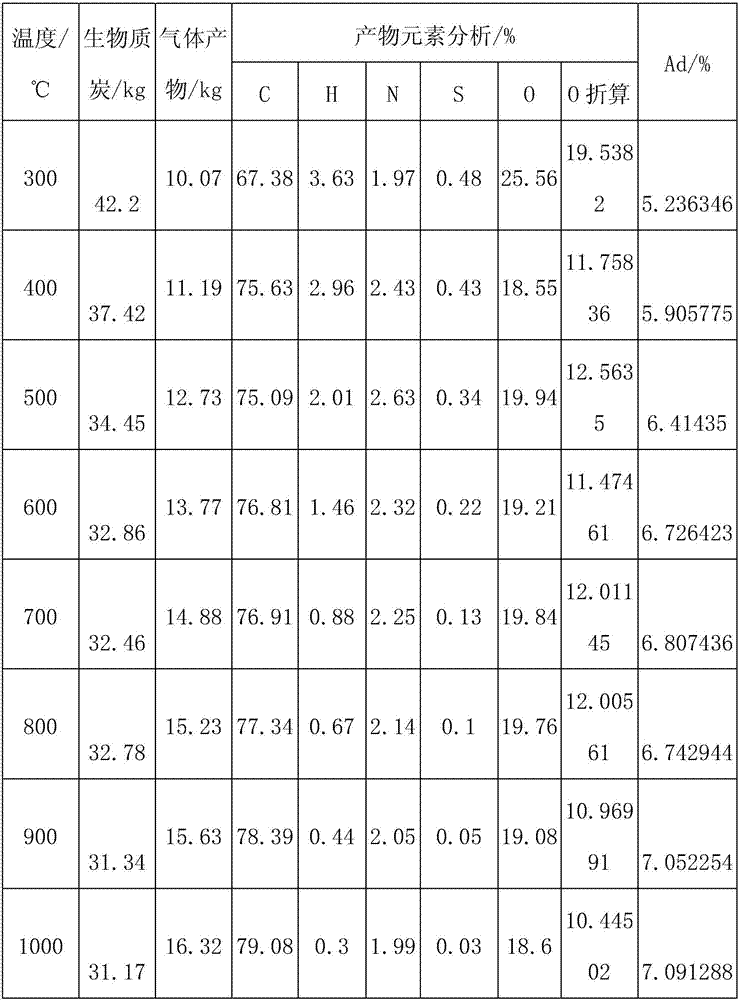

[0030] The industrial analysis and elemental analysis of a kind of straw are shown in attached table 1, and the analysis of pyrolysis products at different temperatures of 100kg is shown in attached table 2.

[0031] Schedule 1:

[0032]

[0033] Schedule 2:

[0034]

[0035] Take carbonization pyrolysis at 600°C as an example:

[0036] Among them, the content analysis of product biomass carbon element: 76.81% [C], 1.46% [H], 2.32% [N], 0.22% [S], 19.21% [O], 11.47% [O] converted, 6.73% ash.

[0037] Gas product analysis (mass fraction): 11.42% CH 4 , 42.36%CO 2 , 25.12%H 2 , 21.1% CO, n 总 is 0.51, and the specific heat capacity of the mixed gas is 286711.1kJ / kg (gas product molar conversion: 0.058511CH 4 , 0.217033CO 2 , 0.128703H 2 , 0.108106CO)

[0038]From attached table 1 and attached table 2, it can be seen that every 100kg of straw can produce about 35kg of biomass charcoal, its carbon content is more than 75%, and its ash content is about 6%, while t...

Embodiment 2

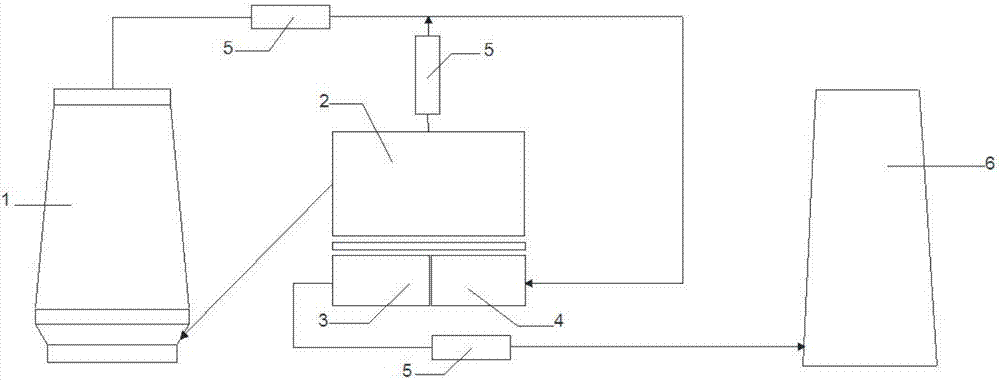

[0040] Such as figure 1 As shown, the process flow diagram of the method of biomass carbonization instead of pulverized coal injection in the blast furnace of the present invention, firstly, the straw is screened by a screening machine to remove impurities, and then the straw is dried to a moisture content lower than 7% by a dryer. Under the conditions of 250-300° C., pressure of 78 MPa, and humidity of less than 7%, the straw is subjected to biomass extrusion molding. Carbonize the machine-made rods obtained by extruding in an external heating carbonization furnace to obtain biomass charcoal and flue gas. The carbonization temperature is 300-1000°C, the charcoal yield exceeds 30%, the fixed carbon content reaches about 80%, and the ash content is about The carbon yield, fixed carbon content and ash content vary with the type of biomass and pyrolysis temperature. The externally heated carbonization furnace uses blast furnace gas and carbonization furnace flue gas to burn and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com