Negative-pressure ignition control device for sintering iron ore

An ignition control and iron ore technology, applied in the metallurgical field, can solve problems such as blockage of bulk materials, and achieve the effect of maintaining normal operation, avoiding blockage and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

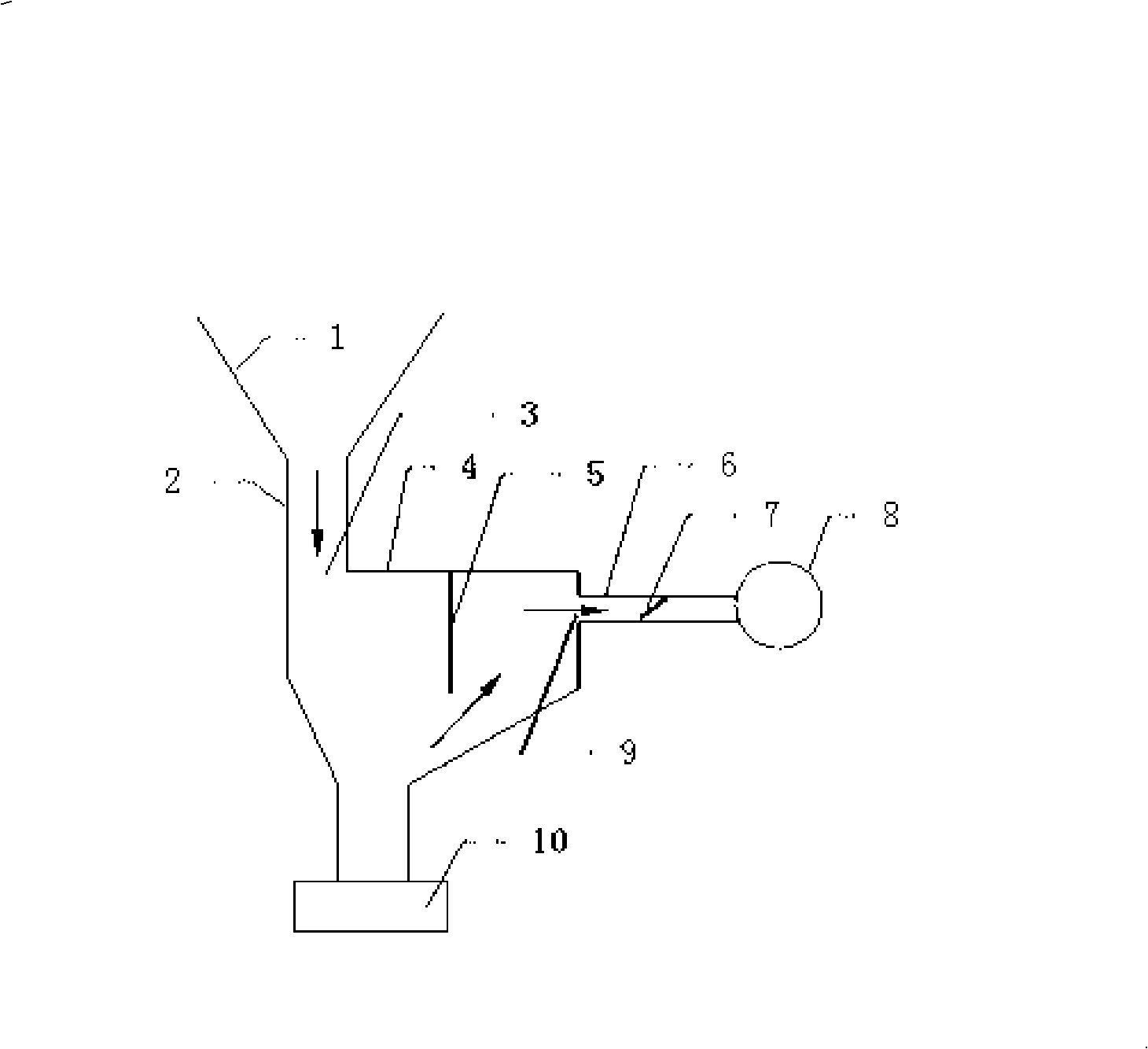

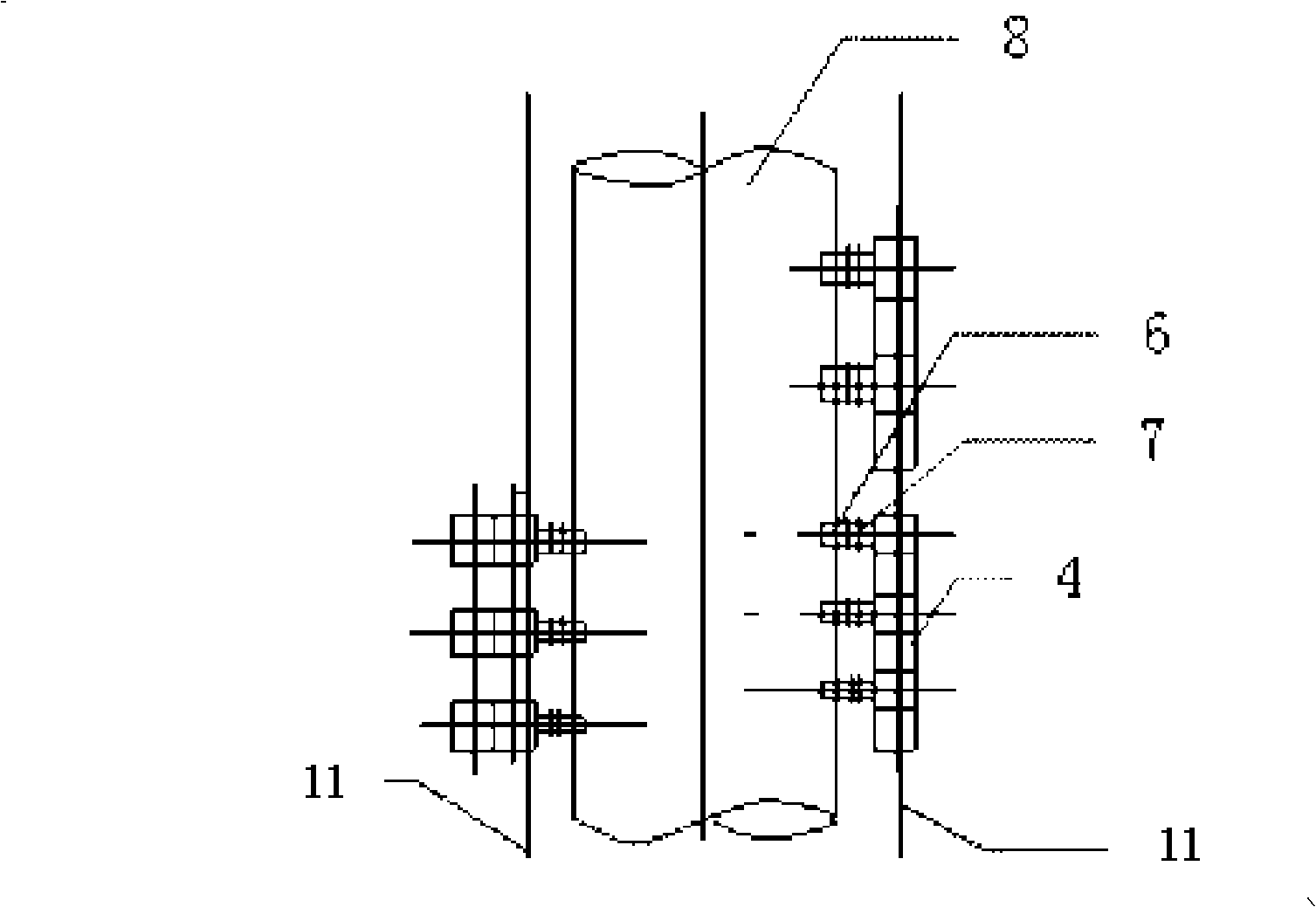

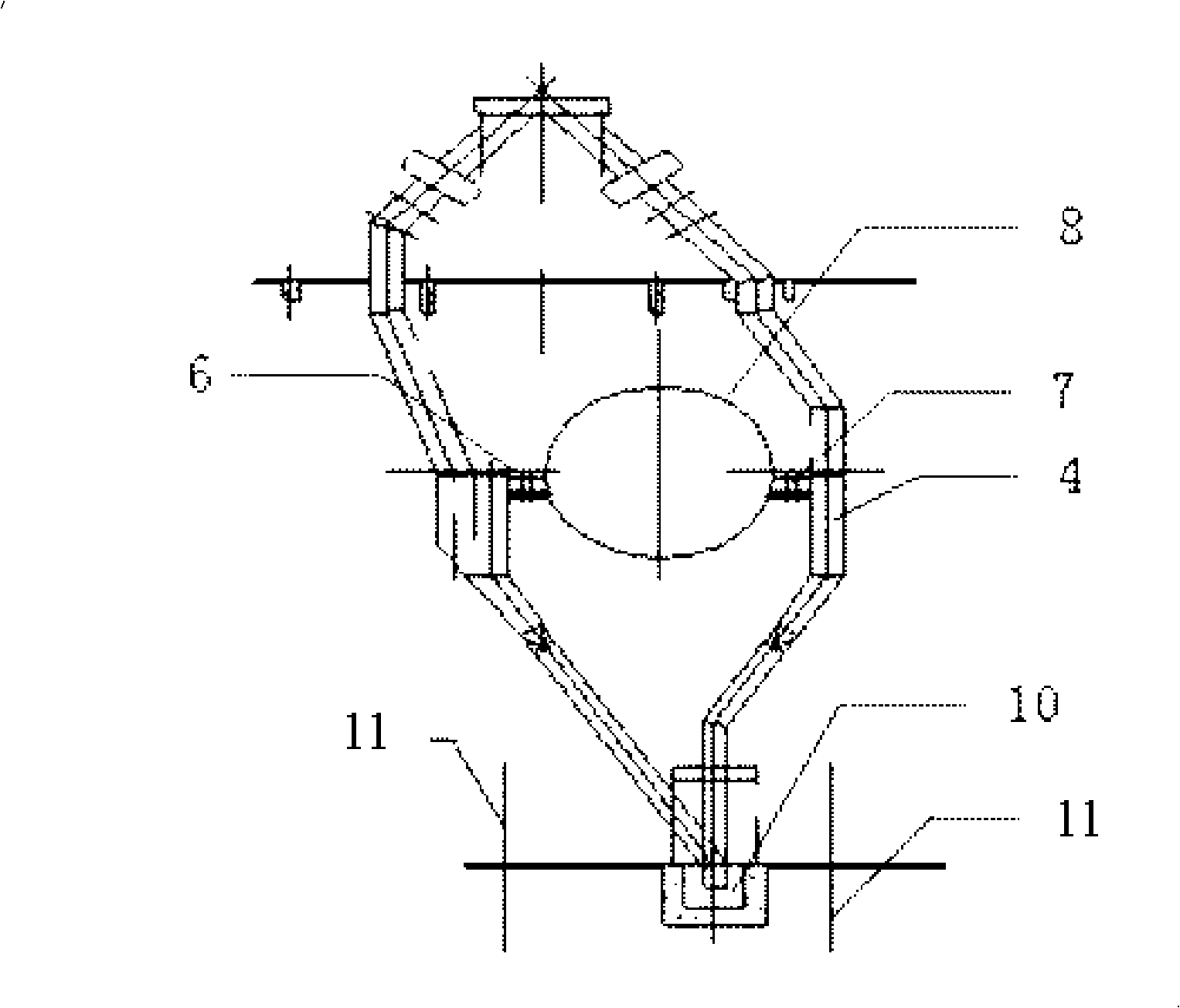

[0024] in a 130m 2 The negative pressure ignition control device for iron ore sintering of the present invention was tested on the sintering machine, and the 1#, 2#, and 3# bellows under the igniter at the head of the sintering machine were modified. The bellows standpipe 2 is connected to the large flue 8 through a turning pipe 4 and a bypass pipe 6 with an electric butterfly valve 7. The inner wall of the turning pipe 4 is installed with a partition 5 perpendicular to the air outlet direction, and a control electric butterfly valve 7 is installed. electronic control device. The negative pressure ignition control device adopts the control design parameters shown in Table 1.

[0025] Table 1 Design parameters of negative pressure ignition control

[0026]

project

ignition negative

to press

Ignition air volume

ignition wind

box area

Control valve

door diameter

Valve conduction

area

unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com