Method for charging iron ore sintering fuel

A technology for iron ore and fuel, applied in the field of metallurgy, can solve the problems of poor strength, high energy consumption, low output and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

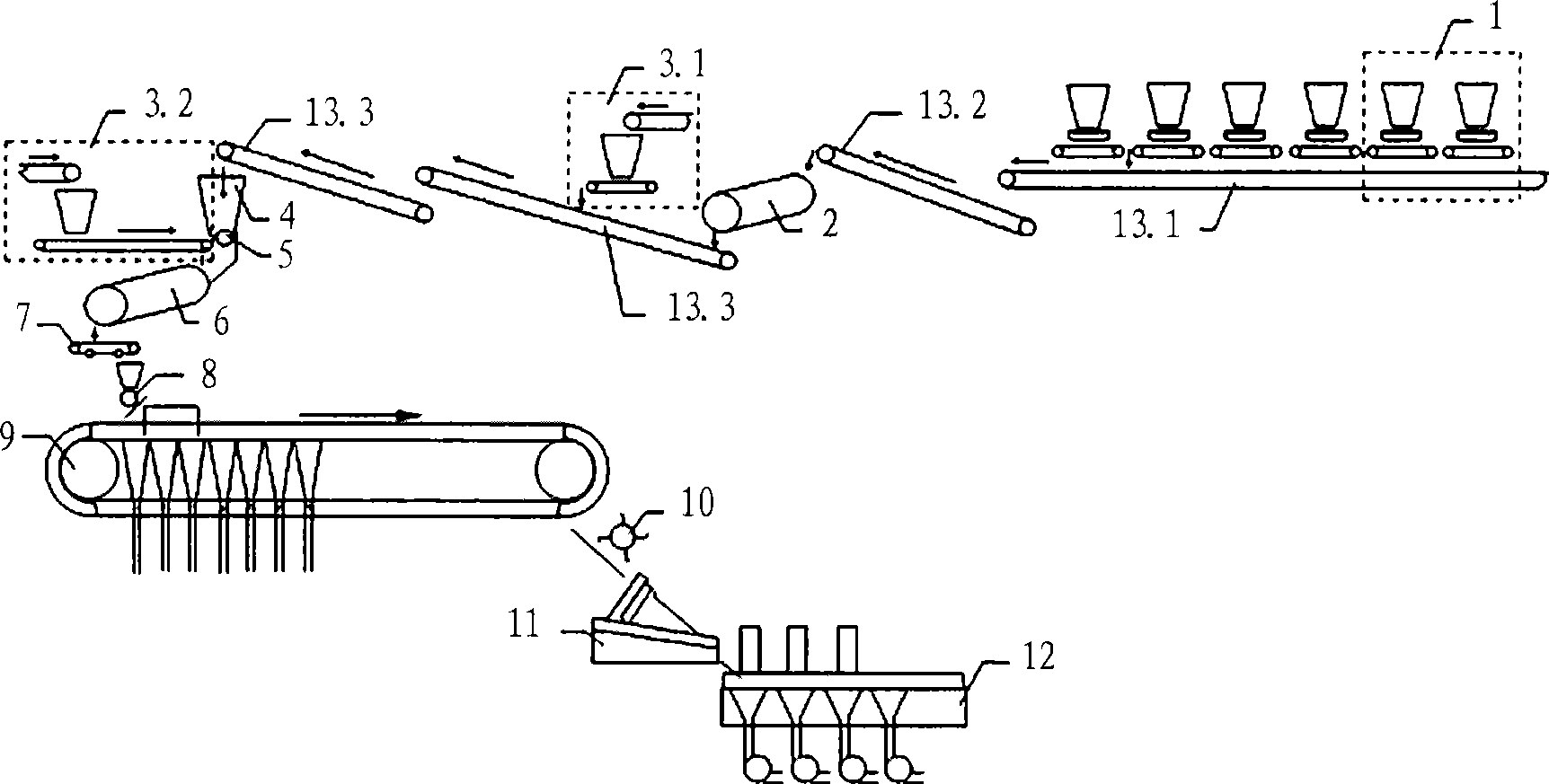

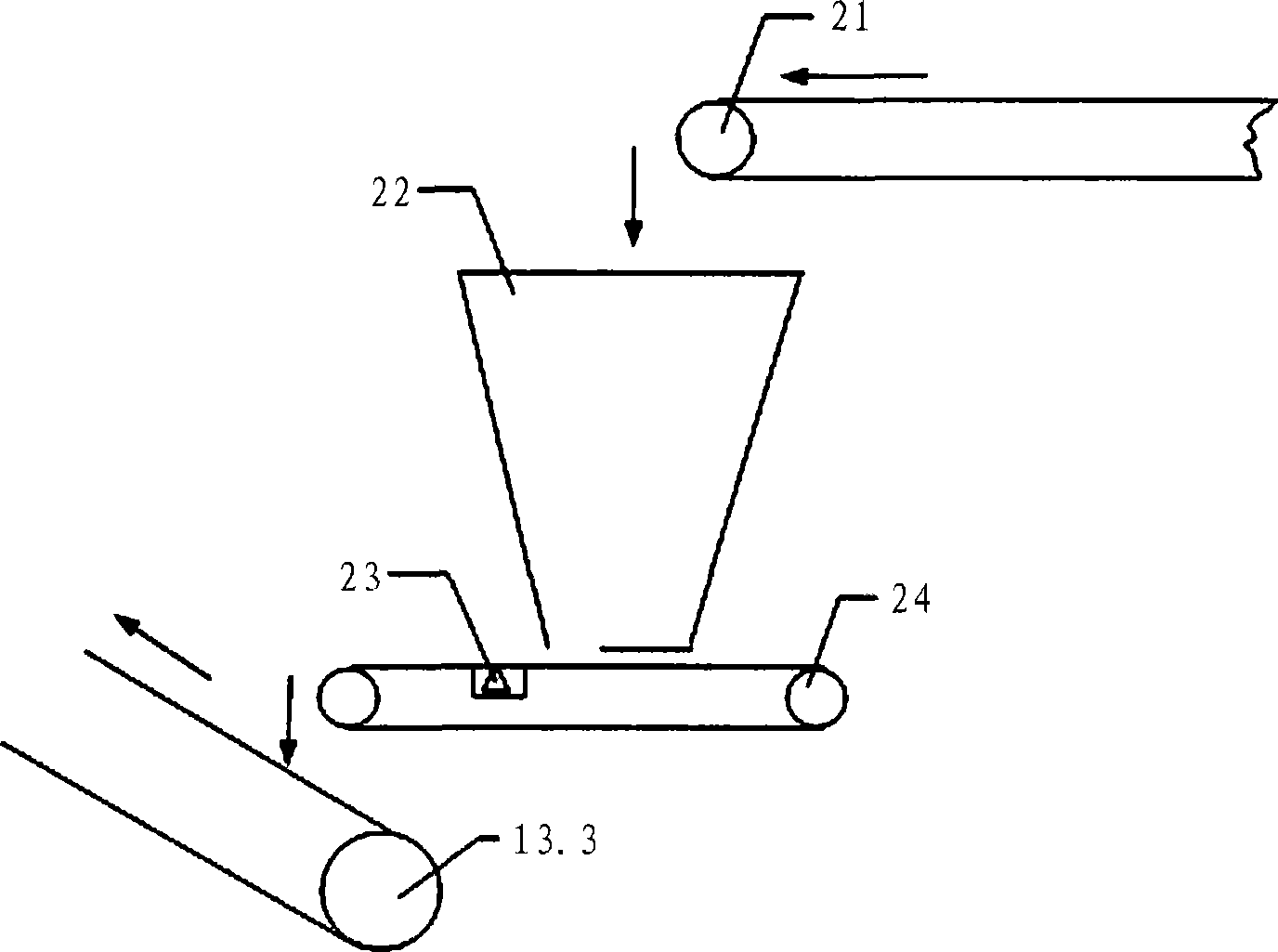

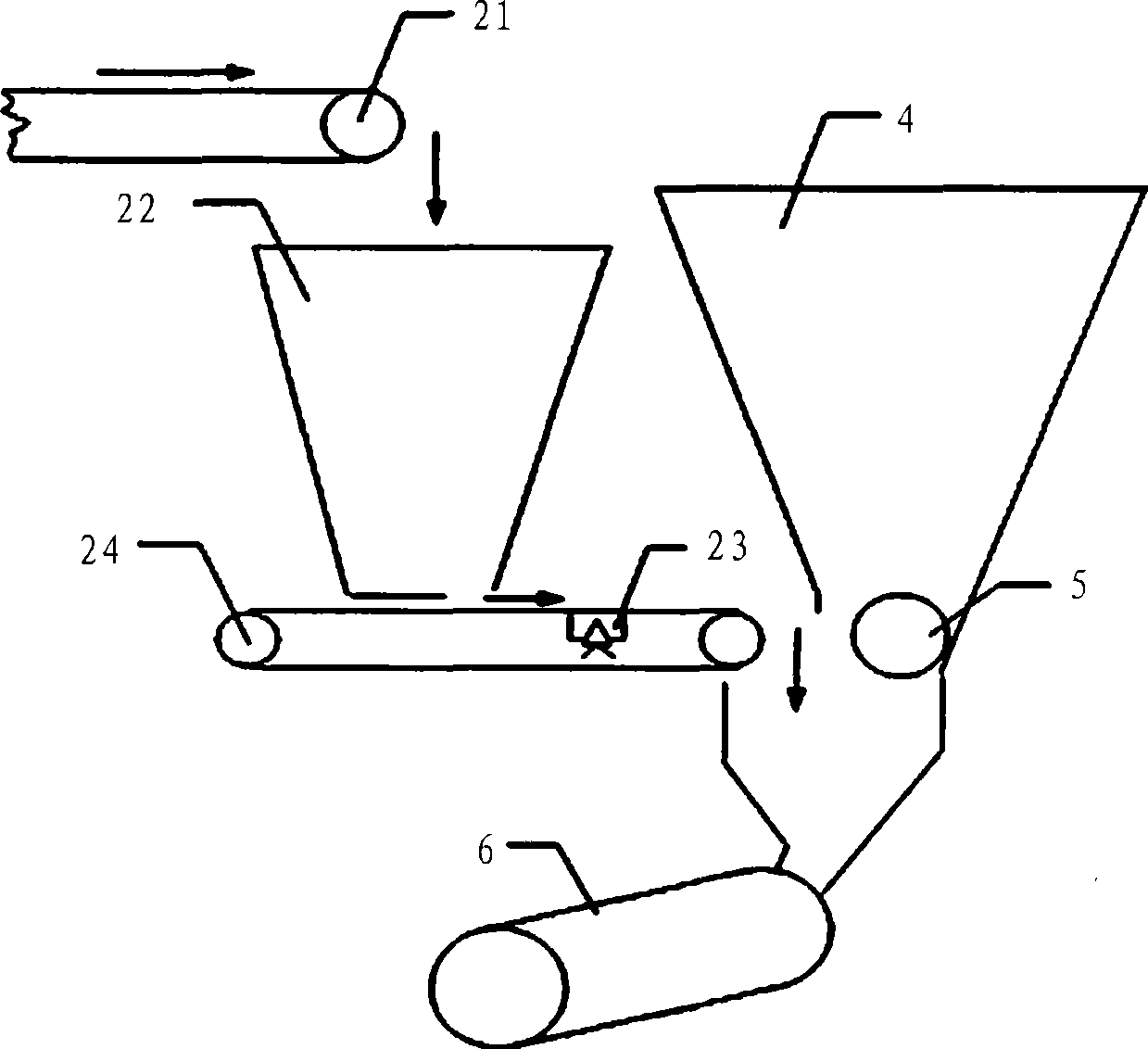

Method used

Image

Examples

Embodiment 1

[0028] According to the method of adding fuel in the first embodiment of the present invention, coke powder, anthracite, and different fuel adding ratios were sintered to produce 5 batches of sintered ore, and the results are shown in Table 1 to Table 3. Among them, the raw materials and formula used are: by weight percentage, 40%-60% of vanadium-titanium magnetite concentrate, 1%-15% of imported fine ore, 1%-20% of ordinary high-grade fine ore, 1%-20% of ordinary medium-grade fine ore %-10%; flux: limestone 1%-15%, quicklime 1%-8%. Fuel: coke powder 4%-6% or anthracite 5%-8%. Sintering machine process parameters: mixed material moisture 6.5-7.5%, material layer 400-600mm, ignition temperature 950-1100°C, sintering negative pressure 11000-14500Pa, main exhaust gas temperature 90-130°C.

[0029] Table 1 The technical parameters of adding the fuel after the secondary parting close to the primary mixing

[0030]

[0031] Note: Batch number 1 in Table 1 is without fuel splittin...

Embodiment 2

[0038] According to the method of the second embodiment of the present invention, the fuel is added twice. The fuel is anthracite in the first addition, and the fuel in the second addition is coke powder. According to the method of the present invention, 6 batches of sinters are produced. The results are shown in Table 4.

[0039] Table 4 The implementation effect of adding the fuel in the secondary part and adding it close to the secondary mixer

[0040]

[0041] It can be seen from Table 4 that after the application of fuel secondary addition technology, the average output of different addition ratios has been increased by 4.2t / h, the increase rate is 2.59%, the solid fuel consumption has been reduced by 0.88kgce / t, and the strength of the drum has also increased A technical effect of 0.13%.

[0042] The method for separately adding fuel of the invention solves the problems of low sintering output, poor strength and high energy consumption of the vanadium-titanium magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com