Pre-selecting and tailings discarding process of lean magnetite ores

A lean magnetite and process technology, which is applied in the field of lean magnetite pre-selection and tailing process, can solve the problems of affecting the effect of pre-selection and throwing tailings, insufficient monomer dissociation degree, waste of grinding energy consumption, etc., so as to reduce grinding Amount and follow-up work load, reduce excessive loss of iron metal, reduce the effect of grinding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

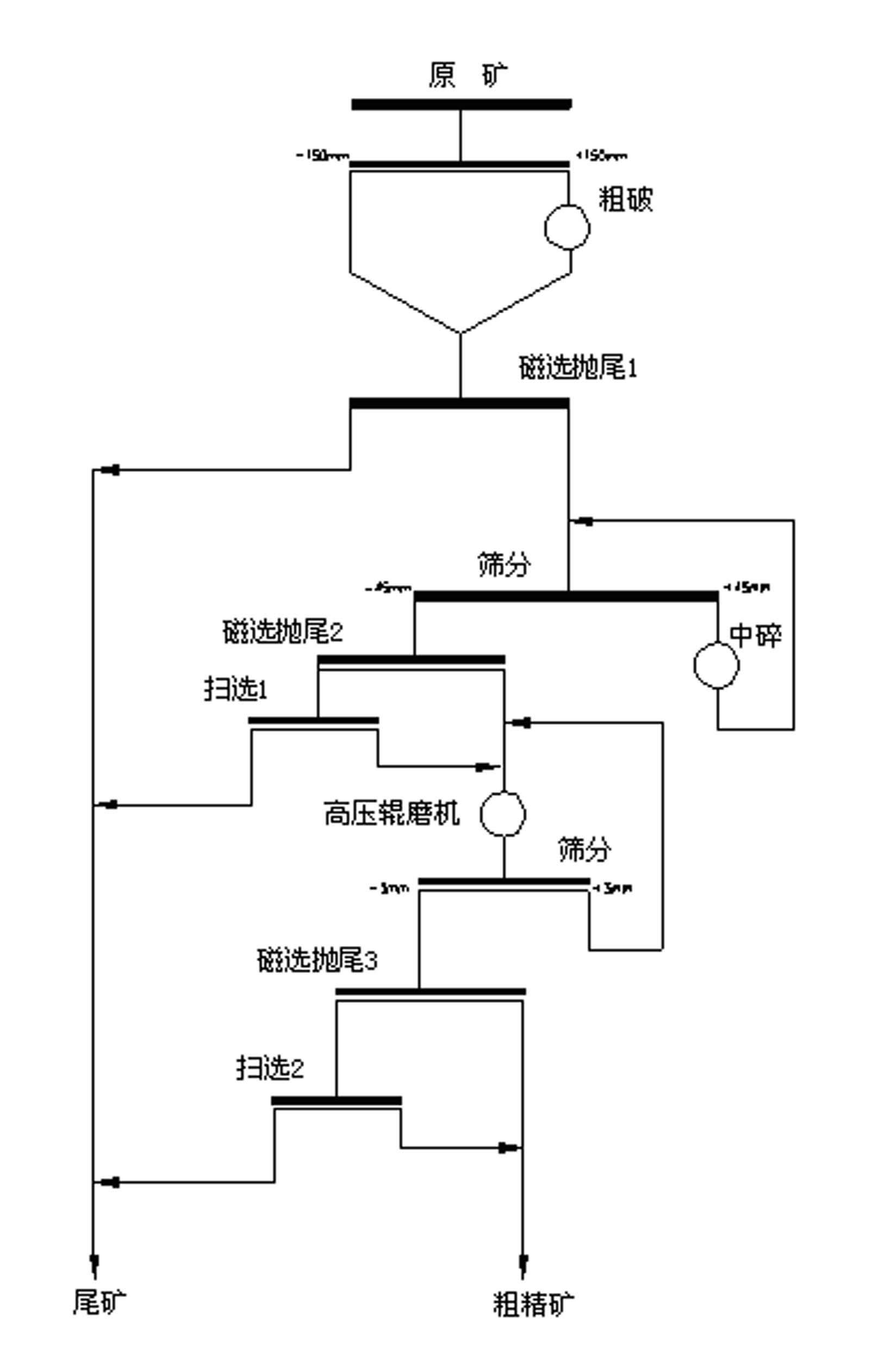

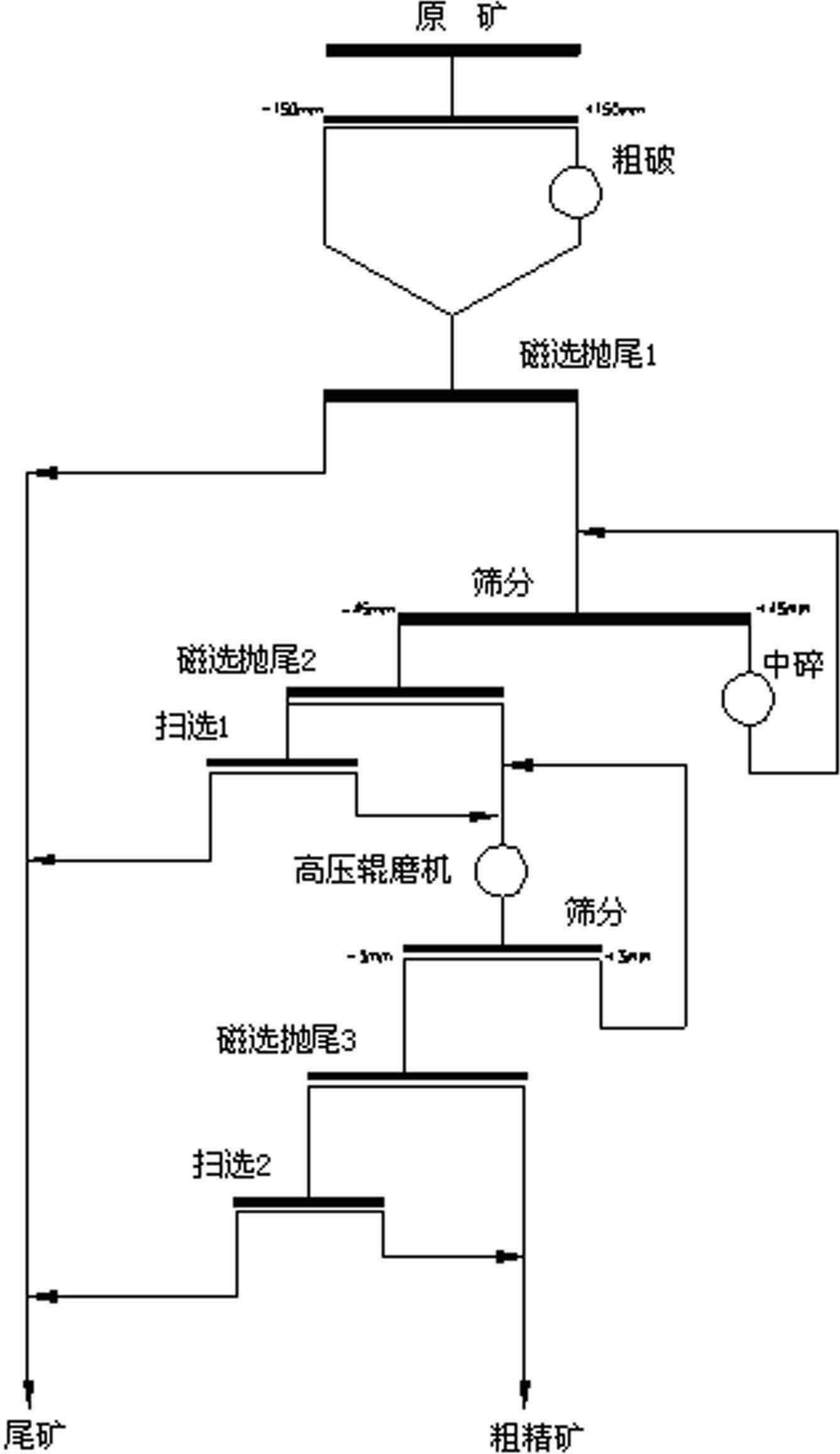

[0028] Such as figure 1 As shown, a. The raw ore is pre-selected and screened, the screen size is 100~200mm, the product on the screen is coarsely crushed and mixed with the product under the screen, and then it is pre-magnetically separated by a magnetic pulley or a dry permanent magnetic separator for large ore Tail throwing operation, throwing away the surrounding rock mixed in mining and part of the dissociated gangue;

[0029] b. The magnetic material after being thrown by the magnetic pulley is screened through a double-layer sieve, the mesh size of the upper layer is 40~50mm, and the mesh size of the bottom layer is 15~20mm; the products on and under the bottom layer are subjected to dry permanent magnetization Magnetic separation tailing operation, and sweeping operation on tailings, the magnetic products obtained by sweeping are mixed into the magnetic products of tailing operation; after the products on the screen are crushed, return to the double-layer screen for i...

Embodiment 2

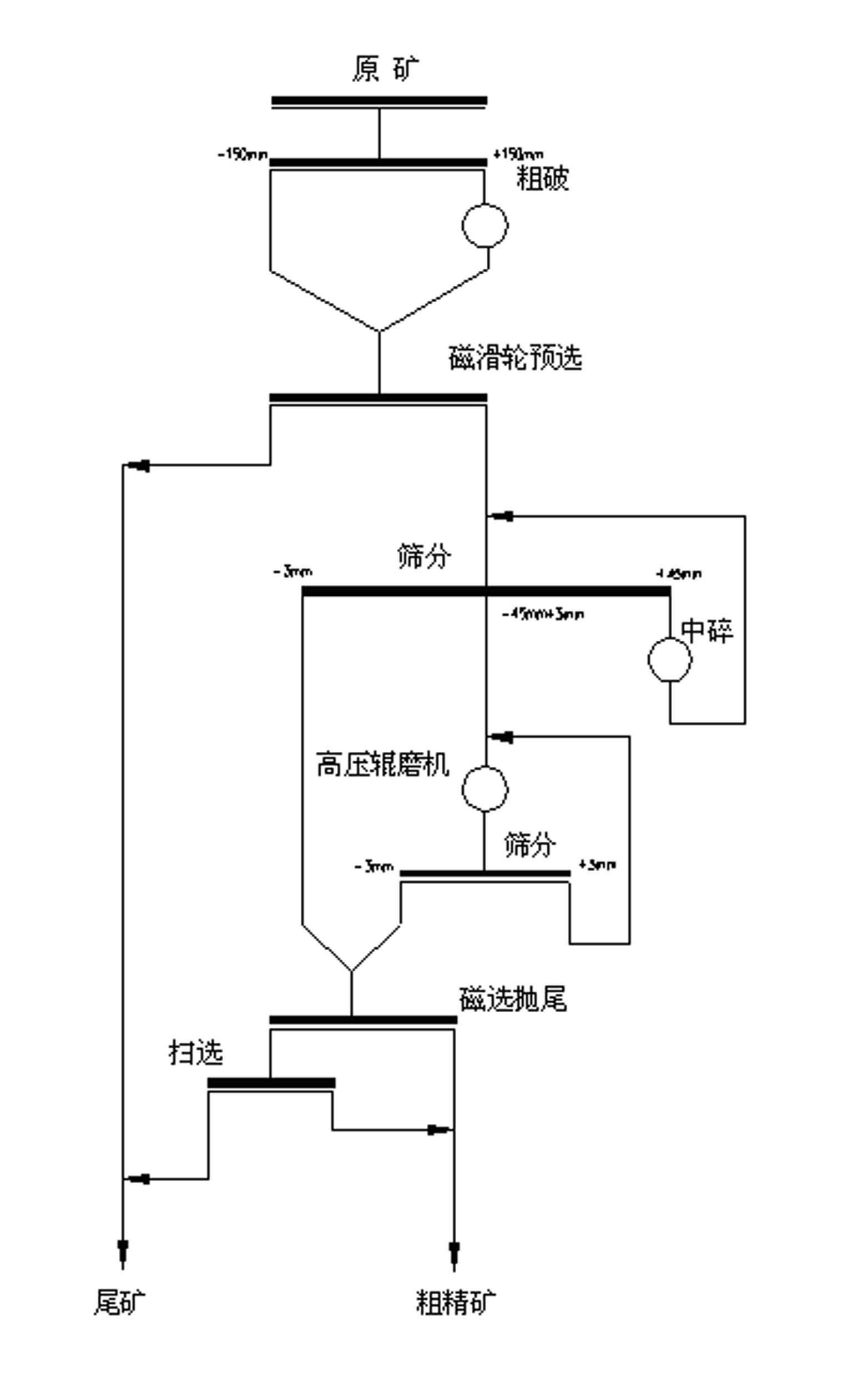

[0034] Such as figure 2 As shown, the difference between this embodiment and Example 1 is that the double-layer sieve in step b selects the sieve size of the upper sieve to be 40-50mm, and the sieve size of the bottom sieve is the same as that of the high-pressure roller mill. The size is the same (3~5mm), the bottom sieve is directly fed into the CTB1021 wet permanent magnet magnetic separator or CG3 up-suction dry permanent magnetic separator for tailing operation, and the bottom sieve is transported to The high-pressure roller mill is ultra-finely crushed, and the material on the upper sieve is crushed and then returned to the double-layer sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com