Detecting method for iron ore sintering machine air leakage rate

A detection method and air leakage rate technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as large errors, inaccurate testing, and impact on sintering production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

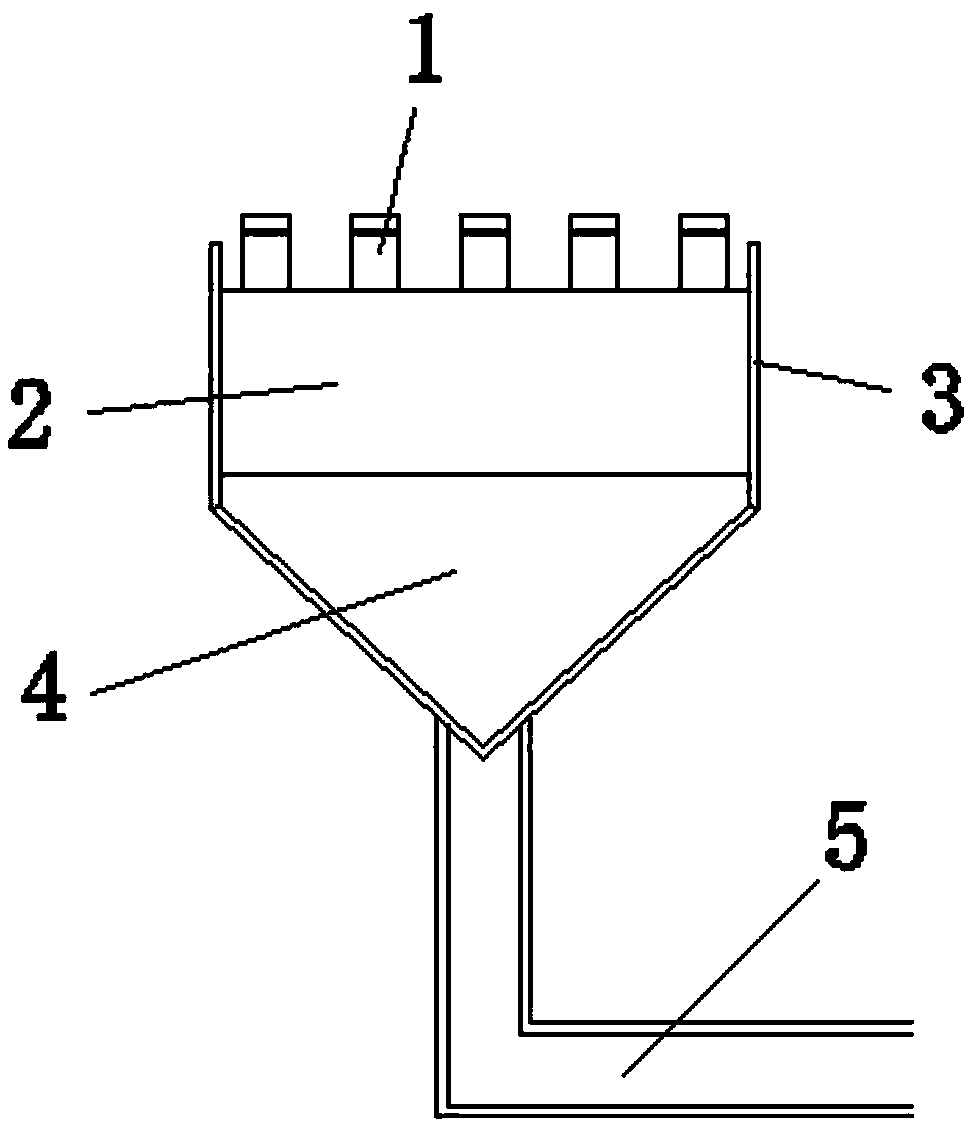

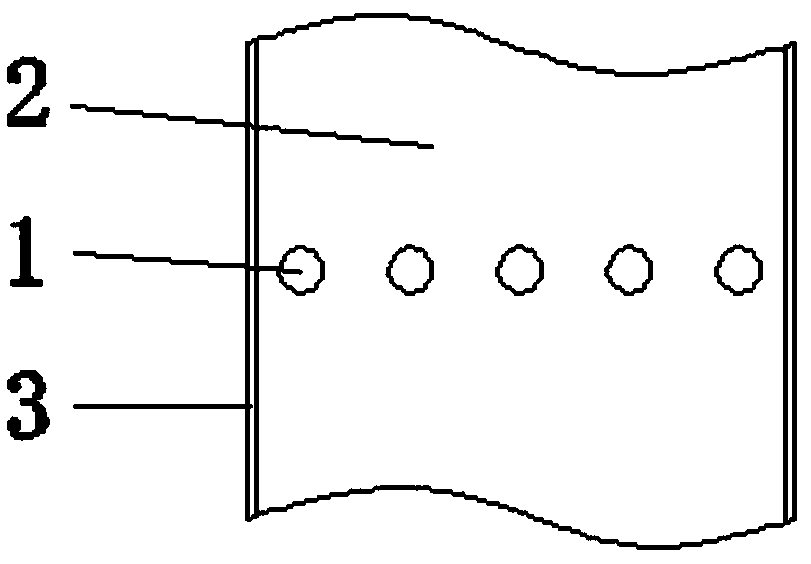

[0076] Below in conjunction with accompanying drawing, the present invention will be further described in detail, so that those skilled in the art can understand more clearly, the method of the present invention is applied to the sintering machine air leakage rate detection of a certain factory of Maanshan Iron and Steel Co., Ltd., and the sintering machine area is 380m 2 , the trolley width is 5.2m, such as Figures 1 to 4 As shown, the specific steps are as follows:

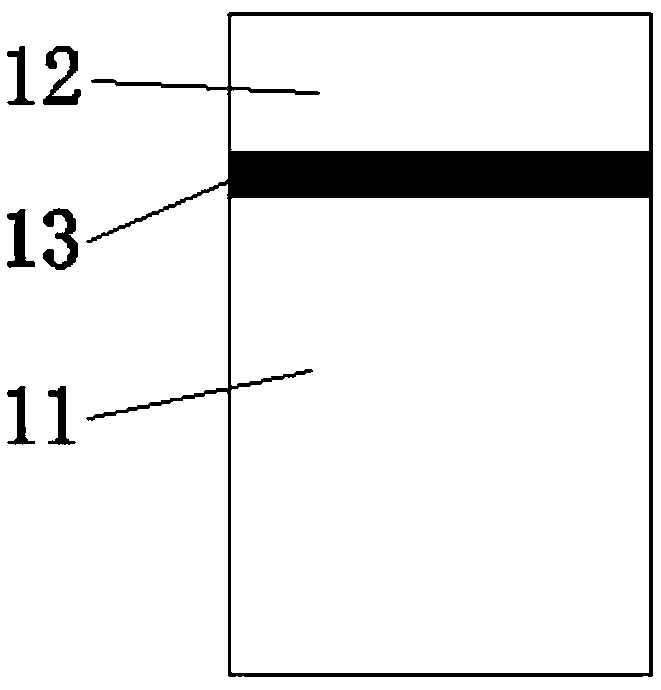

[0077] Step 1: If figure 1 As shown, take an air-introduction circular pipe 11 with an inner diameter of 120mm and a length of 350mm, and an impeller anemometer 12 with an inner diameter of 120mm is arranged on the air-induction circular pipe 11, and the upper end surface of the air-induction circular pipe 11 and the impeller anemometer 12 are lowered. A sealing ring 13 is provided between the end faces to obtain a detection device 1;

[0078] Step 2: If Figures 2 to 4 As shown, five detection devices 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com