Gas chromatography programmed heating injection system and method using vortex effect

A technology of programmed temperature rise and gas chromatography, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low refrigeration efficiency, unfavorable promotion and use, high maintenance cost, etc., achieve great practical value and promotion value, and light weight , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

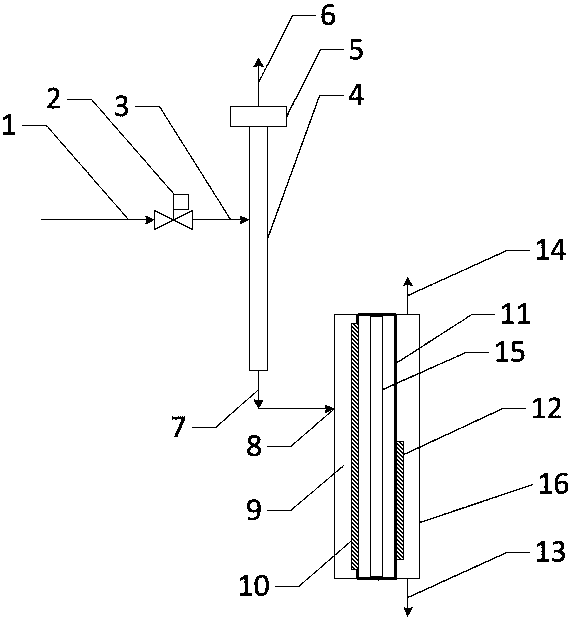

[0045] The specific operation process of this system is: when the system starts to work, the injection port is in a high temperature state, the compressed air passes through the control valve 2 to control the total gas volume entering the vortex tube 4, the gas passes through the vortex tube 4, and the inner generator generates heat and cold Two streams of gas, the gas at the cold end is discharged from the outlet 7 of the cold end of the vortex tube, and enters the inlet of the cold trap of the inlet through the pipeline to cool down the inlet, and the temperature of the gasification chamber is measured by the temperature sensor 12. When the temperature reaches the set temperature . The total gas volume entering the vortex tube 4 is reduced by the control valve 2, the refrigerating capacity of the vortex tube is reduced, the heating device 10 is turned on, and the gasification chamber of the inlet is controlled at a set temperature through dynamic balance. Inject the sample, ...

Embodiment 2

[0047] The specific operation process of this system is: when the system starts to work, the injection port is in a high temperature state, the compressed air is controlled by the control valve 2 to control the total gas volume entering the vortex tube 4, and the gas in the vortex tube 4 passes through the generator in the vortex tube 4 To generate two streams of hot and cold gases, open the control valve 2 to increase the total gas volume entering the vortex tube 4, adjust the regulating valve 5 at the hot end of the vortex tube, increase the gas output at the cold end, and accelerate the reduction of the inlet temperature. The gas at the cold end is discharged from the outlet 7 of the cold end of the vortex tube, and enters the inlet of the cold trap of the injection port through the pipeline to cool down the temperature of the injection port. The temperature of the gasification chamber is measured by the temperature sensor 12. Adjust the valve 5 to gradually reduce the gas t...

Embodiment 3

[0050] The compressor stores the compressed air in the air storage tank, and enters the vortex tube through the gas dryer through the control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com