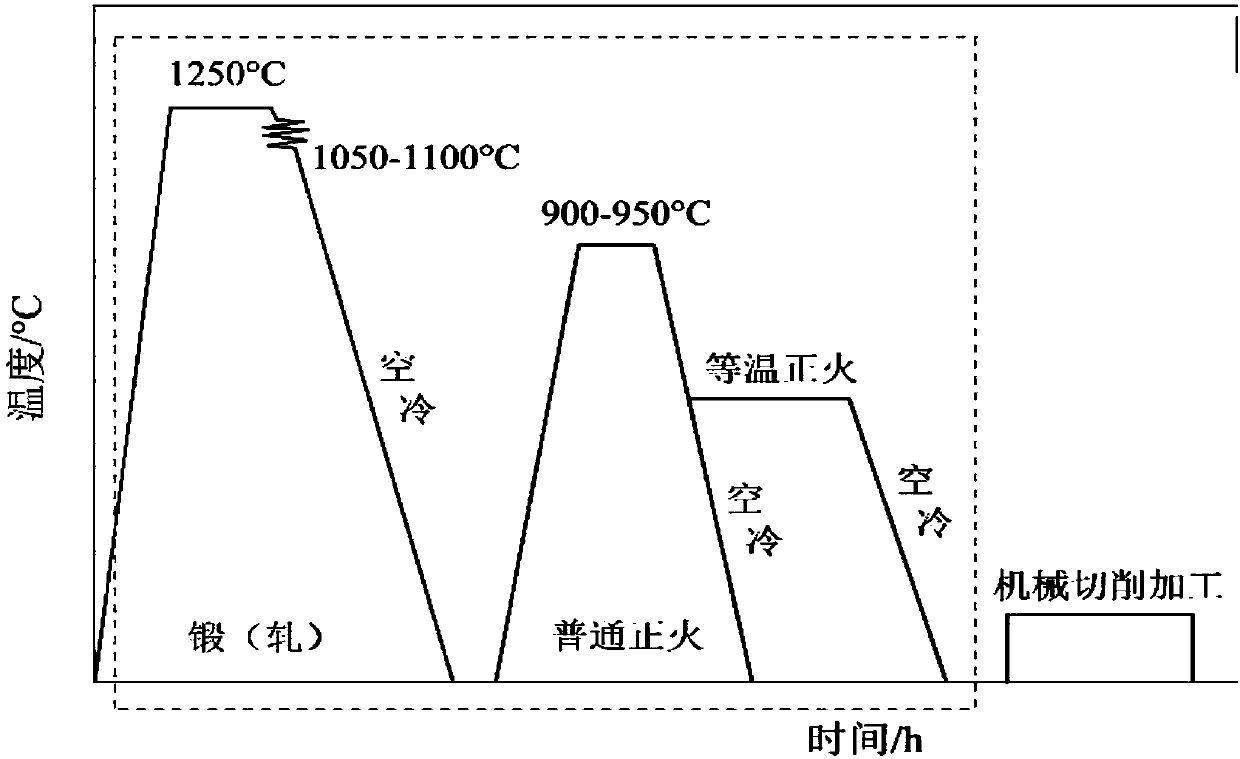

Alloy carburizing steel pretreatment method for changing network ferrites and acicular ferrites in microstructure

A technology of alloy carburizing steel and acicular ferrite, which is applied in the field of alloy carburizing steel pretreatment to change the reticular acicular ferrite in the microstructure, can solve the problems of large hardness fluctuation, coarse microstructure, and inability to Solve problems such as reasonable grain size, easy subsequent cutting, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

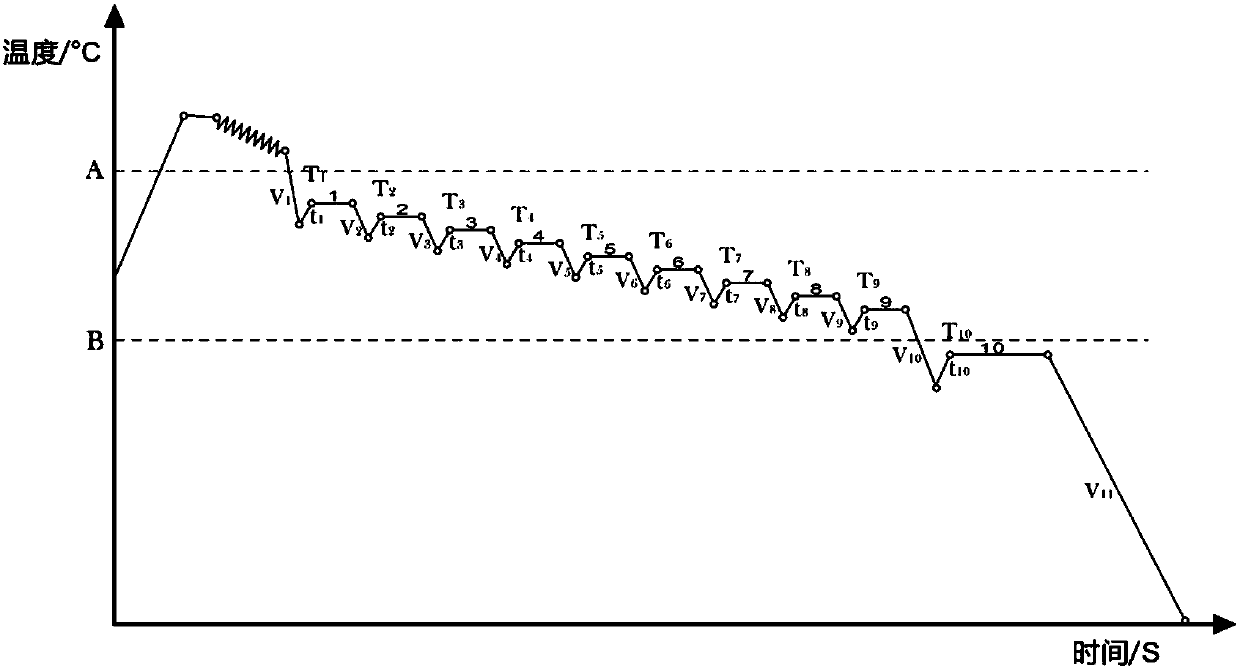

[0052] Example 1: Test Part No. #1

[0053] Adopting the heat treatment process of fast cooling and slow cooling after forging and rolling, and then holding for a certain period of time (see the following processing steps), without precise control of the process steps, it can be verified that the coarse forging grains affect the microstructure of the parts after pretreatment Impact. Since no multi-stage precise control was adopted, the forging was stopped and quickly cooled to 750 degrees, then air-cooled to 600 degrees, and then placed in a holding furnace at 620 degrees for 66 minutes of heat preservation.

[0054] The specific holding temperature (and holding time) of the above process at different stages and the control range of cooling speed at different stages are as follows:

[0055] T3=750°C, T9=600°C, T10=620°C;

[0056] t3=5sec, t9=5sec, t10=66min,

[0057] v3=1.62°C / sec, v9=1.41°C / sec, v10=0.11°C / sec v11=0.15°C / sec.

[0058] Such as Image 6 As shown, what is o...

Embodiment 2

[0059] Example 2: Test Part No. #2

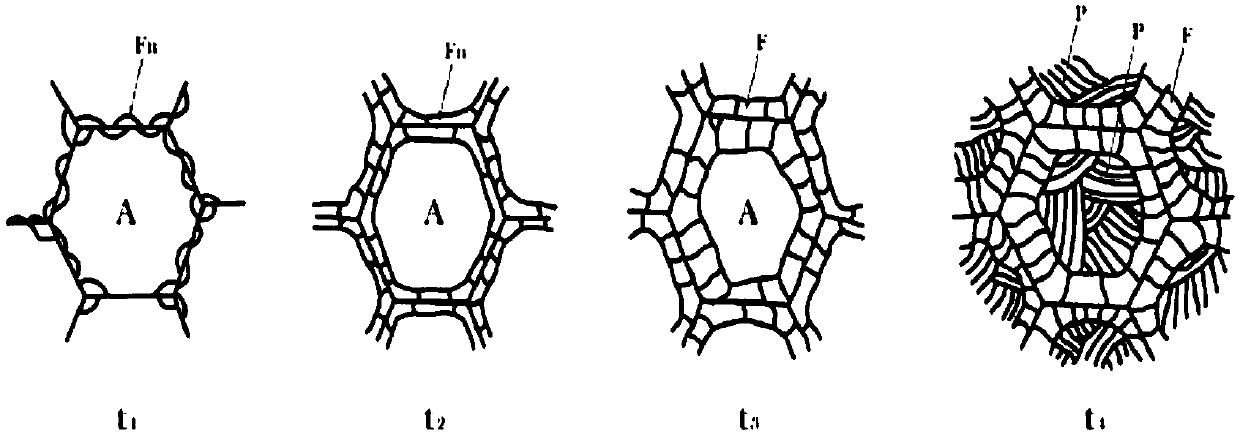

[0060] With a partially improved heat treatment process (see treatment steps below), without precise control of all process steps, it can be found that the influence of coarse forging grains on the microstructure is improved (reticular ferrite begins to thicken). However, there are still a considerable amount of abnormal reticular ferrite that has not had time to become massive, and there is acicular ferrite (Widmanite) inside the reticular ferrite grains (such as Figure 7 shown). The hardness is HB198, and the grain size is grade 3. It is still higher than the requirements of conventional gear blanks (HB160-190, grain size 5-8), and at the same time, the acicular ferrite (or "Widmanite") formed inside a large number of grains will cause subsequent carburization The heat-treated tissue genetics still cannot meet the customer's standard requirements.

[0061] The specific holding temperature (and holding time) of the above process at dif...

Embodiment 3

[0065] Example 3: Test Part No. #3

[0066] By adopting the high-efficiency heat treatment method of the present invention (see the following treatment steps and precise control parameters), all process steps are precisely regulated, and the adverse effects of coarse forging grains on the microstructure are completely improved. Such as Figure 8 As shown, the existence of network and acicular ferrite is completely eliminated, and 100% block ferrite and pearlite can be obtained. The hardness is HB171, and the grain size is 6 grades, which has met the customer's requirements for the microstructure and hardness of the gear blank in all aspects (HB160-190, grain size 5-8 grades). Since there is no non-equilibrium microstructure, it will not bring tissue genetic damage to the heat treatment after carburizing, so it can be used to replace the existing discontinuous heat treatment method to achieve the dual goals of organizational performance and energy saving.

[0067] The specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com