Method for preparing spherocrystal toughening amorphous-based composite

A composite material and toughening technology, which is applied in the field of amorphous matrix composite materials, can solve the problems of low plasticity and toughness of materials, small resistance to shear band expansion, etc., and achieve high strength, excellent mechanical properties, and good fracture plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

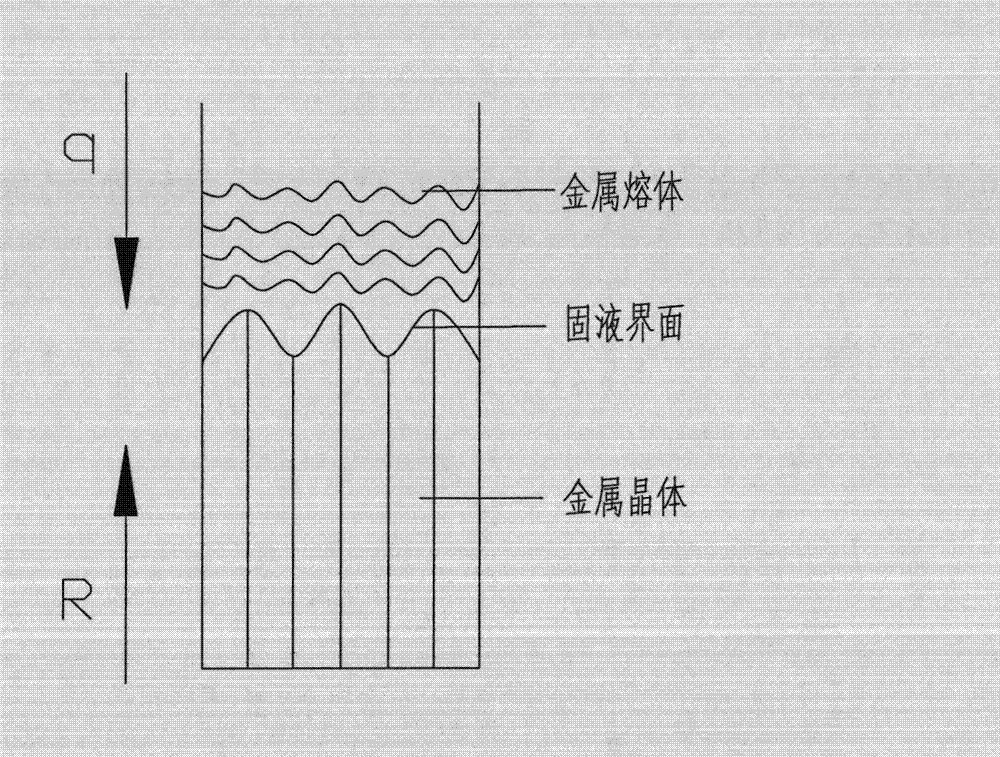

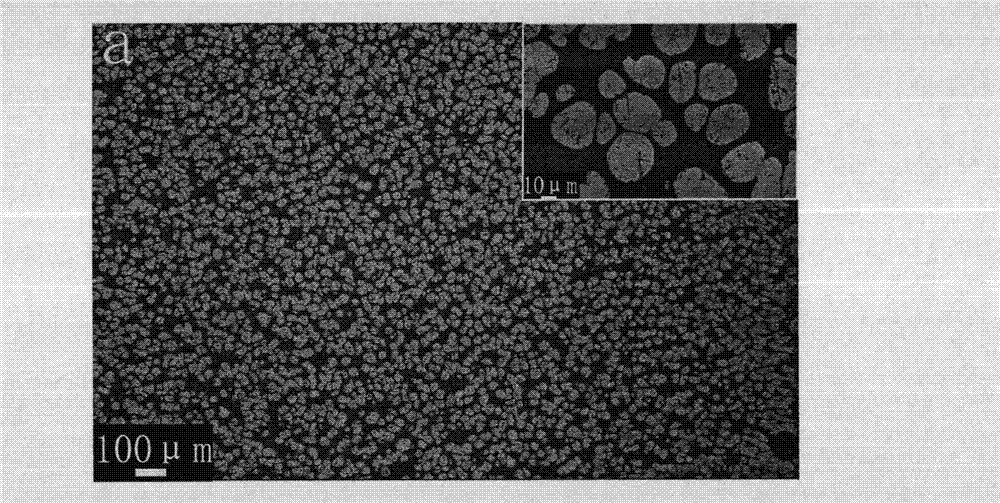

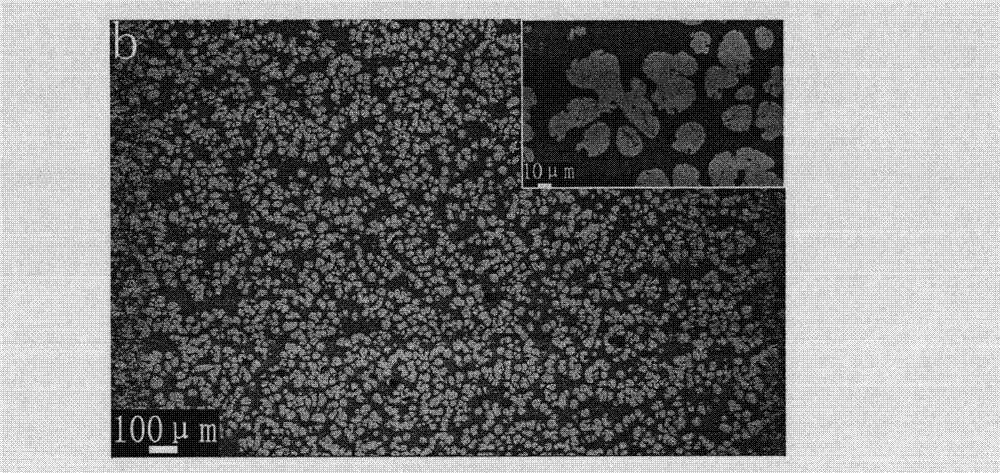

[0015] The present invention adopts semi-solid insulation spheroidization composite liquid metal cooling directional solidification method to prepare the composition as Zr a Ti b Nb c Cu d Ni e be f The spherulite toughened amorphous matrix composite material, wherein a, b, c, d, e, f represent atomic percentage and a+b+c+d+e+f=100. and with Zr 60.0 Ti 14.7 Nb 5.3 Cu 5.6 Ni 4.4 be 10.0 Described as a preferred embodiment.

[0016] The first is semi-solid heat preservation: the alloy needs to be heated to the two-phase region, in which the melting point of the second phase crystal is higher, and the melting point of the amorphous matrix is lower. The morphology of the crystal phase mainly depends on the thermodynamics and kinetics of its growth. The free energy formula for crystal growth can be composed of two terms, surface area and volume, expressed as follows:

[0017] AG = ΔG i +ΔG v =σ·A+Δg·v (1)

[0018] Among them, σ is the interface energy between the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com