Pressure adjusting structure and pressure cooker having same

A technology for pressure regulation and structure adjustment, which is applied in the field of pressure cookers, can solve the problems that the pressure limit value of the pressure limit valve cannot be adjusted, and achieve the effects of improved reliability, convenient assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

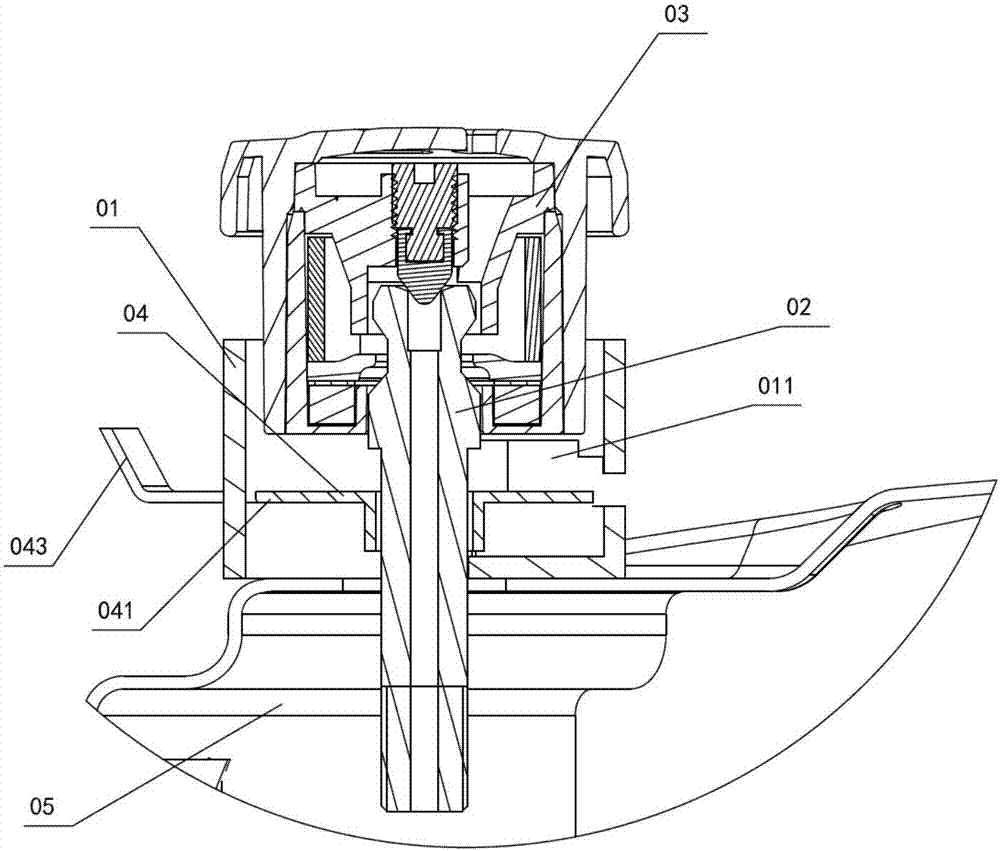

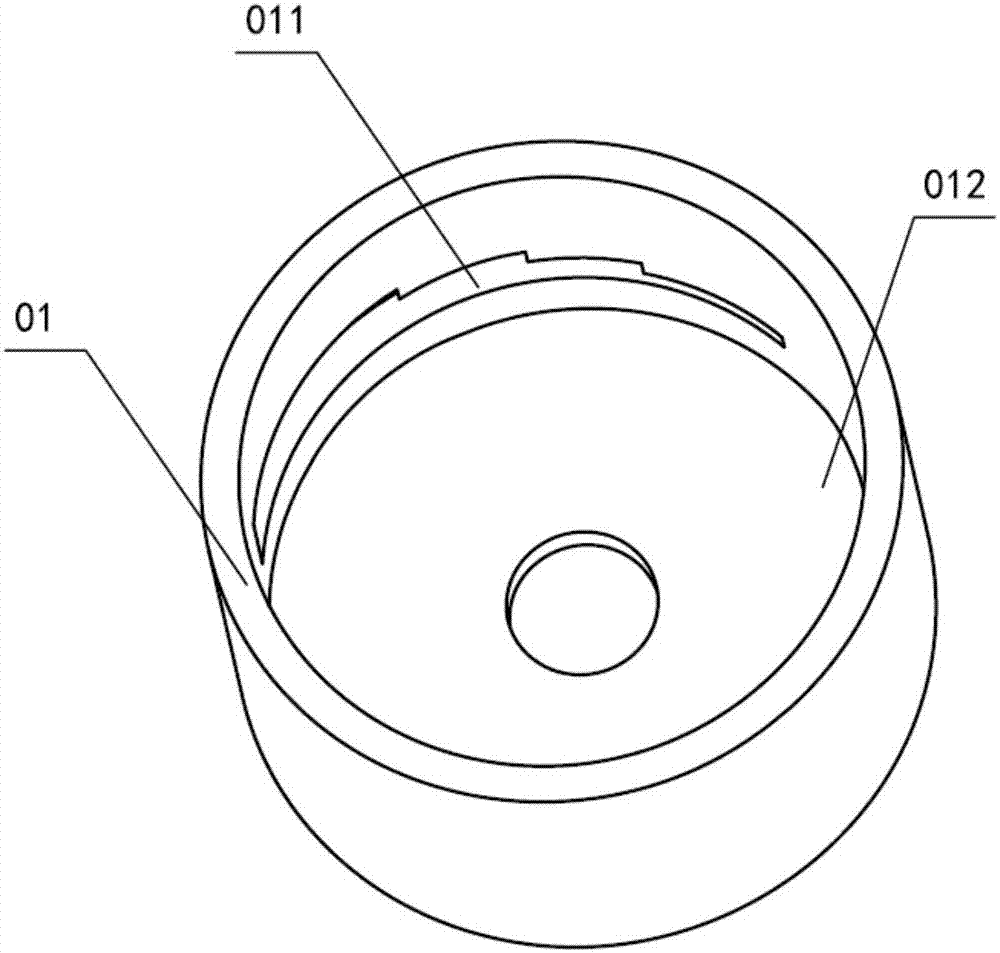

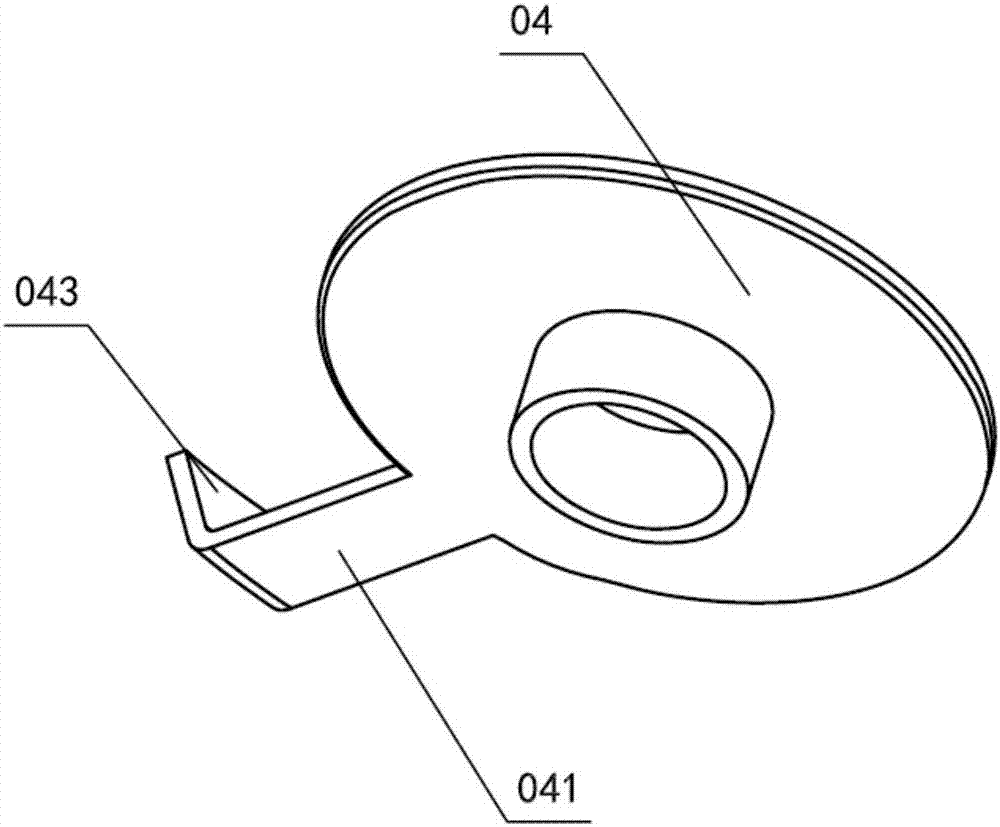

[0050] For the structural diagram of the first embodiment of the pressure regulating structure of the present invention, see Figure 1 to Figure 3 , including the valve seat 01, the exhaust pipe 02 and the magnetic valve body 03, the lower end of the exhaust pipe 02 passes through the valve seat 01, the magnetic valve body 03 is set on the upper port of the exhaust pipe 02, and the valve seat 01 and the magnetic A magnetic pad 04 is arranged between the valve body 03, and the magnetic pad 04 is connected with the valve seat 01 through a magnetic pad adjustment structure for adjusting the up and down position of the magnetic pad; The limit structure on the seat 01, and the extension end 041 arranged on the outer edge of the magnetic cushion block 04, the limit structure and the extension end 041 cooperate with each other, for when the magnetic cushion bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com