Arc additive and laser-assisted thermoplastic forming composite manufacturing device and method

A laser-assisted plastic forming technology, which is applied in the field of additive manufacturing devices, can solve the problems of inability to completely break the columnar crystal structure and limited plastic deformation depth, and achieve the effect of improving comprehensive mechanical properties, sufficient thermal deformation, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

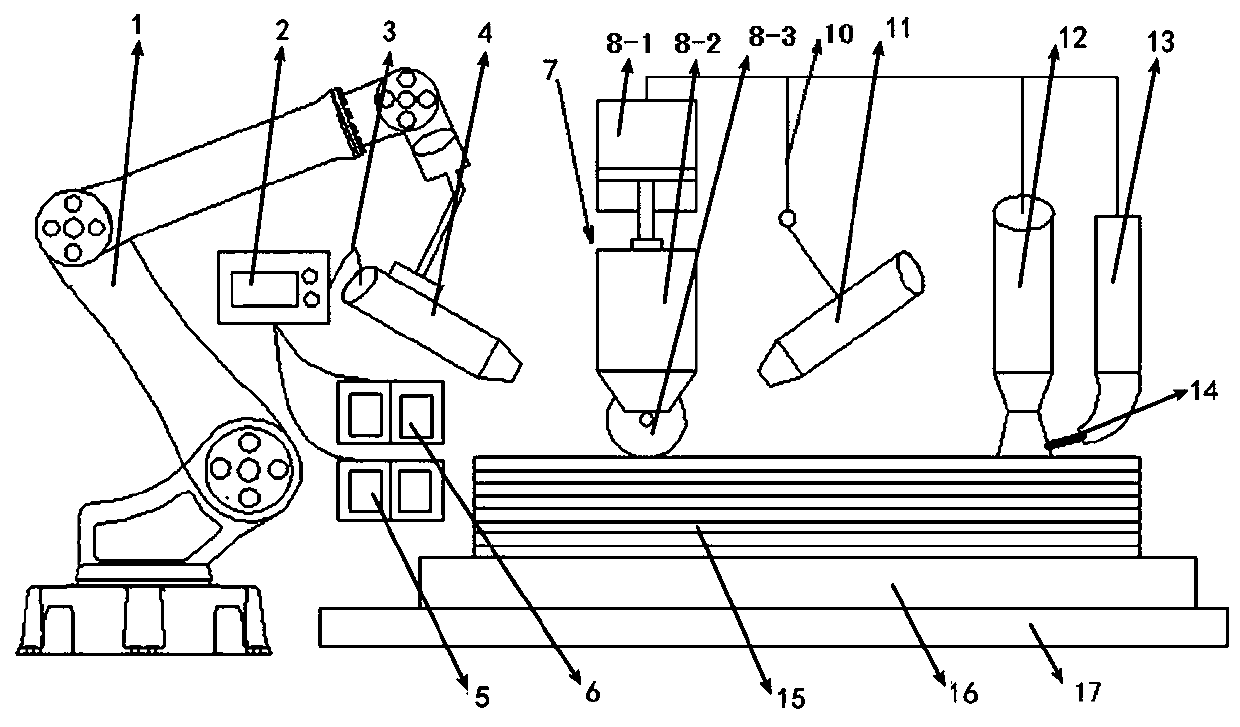

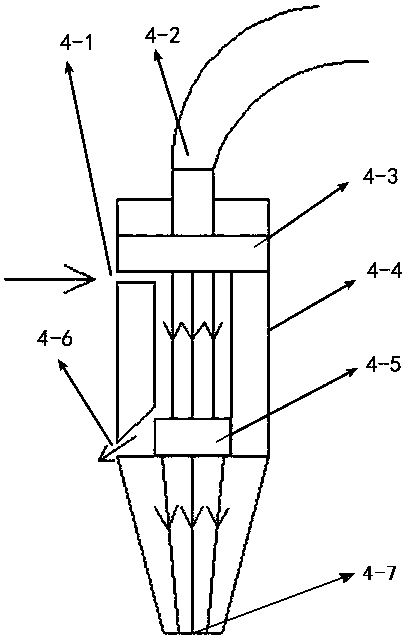

[0027] The structure of the arc additive and laser-assisted thermoplastic forming composite manufacturing device in this embodiment is as follows: Figure 1 to Figure 2As shown, it includes a workbench 17 and a base plate 16 fixed on the workbench 17 by a clamp. A kinematic machine tool is arranged above the workbench 17. An arc additive module and a plastic forming module connected to the kinematic machine tool are arranged above the base plate 16. The arc additive module includes a welding torch 12 and a wire feeder 13 that feeds welding wire 14 to the welding torch 12. The welding torch 12 is connected to a welding power source, and the wire feeder 13 delivers the welding wire 14 required for the addition; A plastic forming mechanism 7 for plastically forming the deposition layer 15, a laser heating module for heating the deposition layer 15 below the plastic forming mechanism 7 is provided on the side of the plastic forming module above the substrate 16, and the laser heati...

Embodiment 2

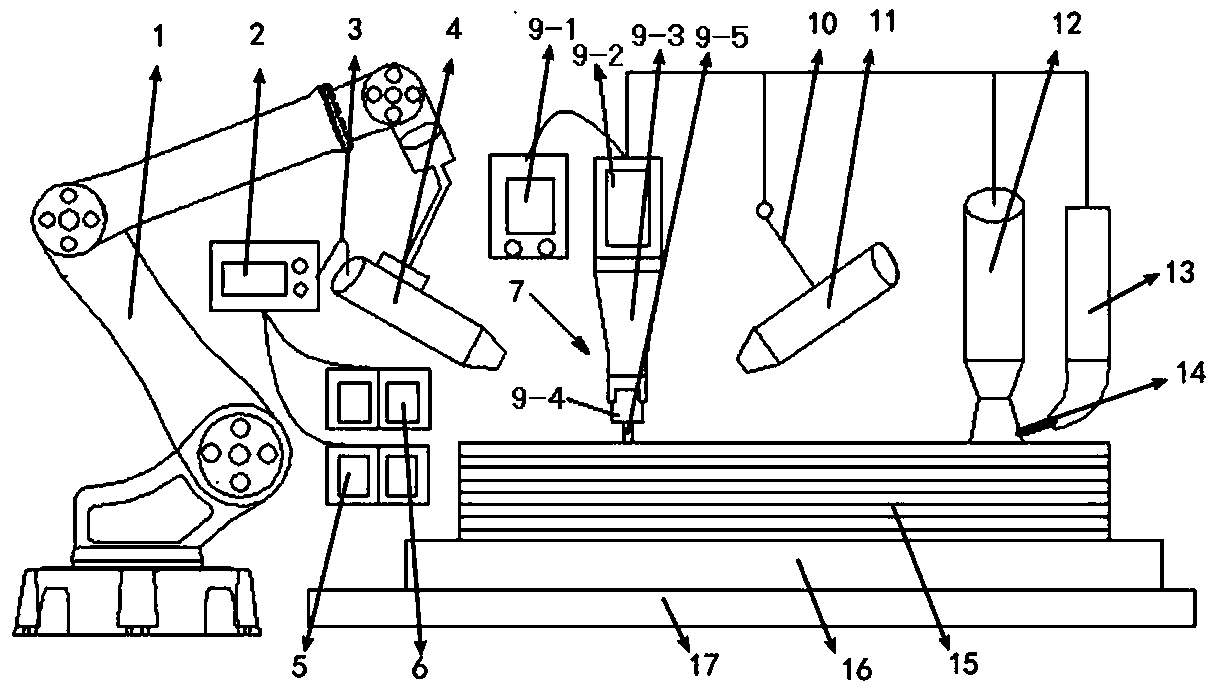

[0032] The structure of the arc additive and laser-assisted thermoplastic forming composite manufacturing device in this embodiment is as follows: image 3 As shown, the only difference between this embodiment and Embodiment 1 is that the plastic forming module of this embodiment is an ultrasonic impact device, and the ultrasonic impact device includes an ultrasonic generator 9-1, an ultrasonic transducer 9-2 and an ultrasonic transducer The amplitude rod 9-3, the ultrasonic transducer 9-2 is connected with the ultrasonic generator 9-1 through a circuit, the ultrasonic horn 9-3 is arranged under the ultrasonic transducer 9-2, and the ultrasonic horn 9-3 The lower end is provided with a clamping handle 9-4, and the lower part of the clamping handle 9-4 holds the impact tool head 9-5, and the ultrasonic horn 9-3, the clamping handle 9-4 and the impact tool head 9- 5 constitutes the plastic forming mechanism 7. The rest of the structure of this embodiment is the same as that of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com