Composite manufacturing system and method of additive manufacturing and laser preheating assisted subtractive cutting

An additive manufacturing and manufacturing system technology, applied in the field of parts processing and manufacturing, can solve the problems of poor machining accuracy, reduced material manufacturing parts, poor applicability of additive manufacturing parts, and complicated processing operations, so as to reduce tool wear, improve mechanical performance, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

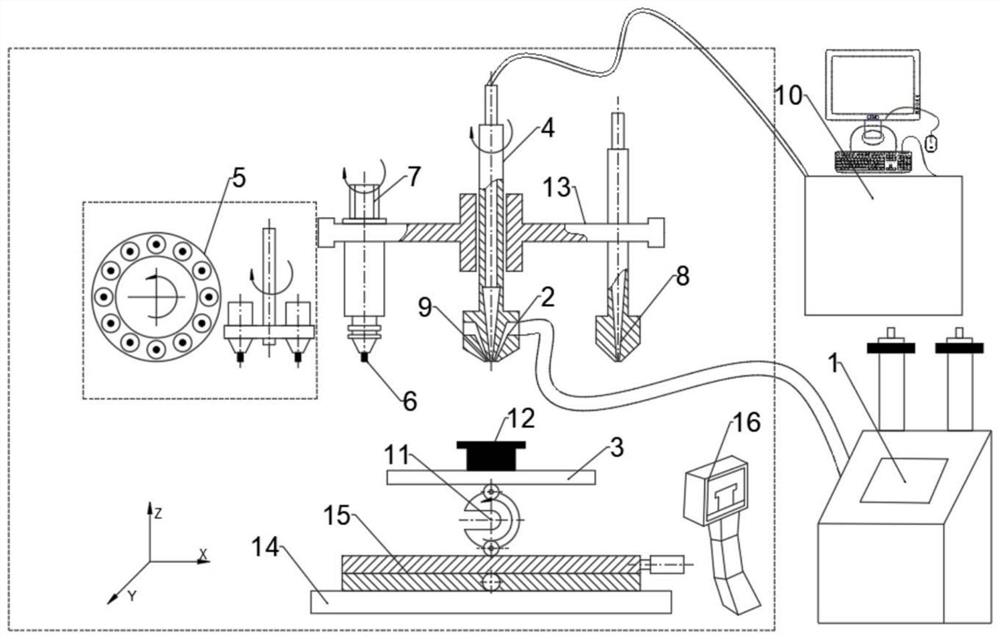

[0052] This embodiment takes 316L stainless steel to manufacture metal parts with hollow structures as an example, using such as figure 1 The shown composite manufacturing system of additive manufacturing and laser preheating assisted subtractive cutting specifically includes the following steps (note: the specific parameters involved are only typical values, in order to better express this invention, do not limit the scope of this invention Effective range of use):

[0053] (1) Generate the additive path and the subtractive path.

[0054] (2) Vacuumize the sealed cavity, and then pass argon gas into the sealed cavity, so that the oxygen content in the sealed cavity is lower than 0.3%.

[0055] (3) The control unit 10 switches the additive manufacturing module to the top of the processing substrate 3 through the module switching unit, turns on the powder feeder 1, and the spherical 316L stainless steel powder is ejected from the powder feeding nozzle 2 to the processing subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com