Equipment for applying ultrasonic cutting to powder laying type additional and subtractive composite manufacturing and machining method

A technology of ultrasonic cutting and processing method, which is applied in the field of additive and subtractive material manufacturing, can solve the problems that affect the service life of the tool, the machining accuracy and surface quality of the workpiece, the heat cannot be taken away in time, and the cutting fluid cannot be used, etc., achieving significant social benefits, The effect of novel structure, improving processing accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

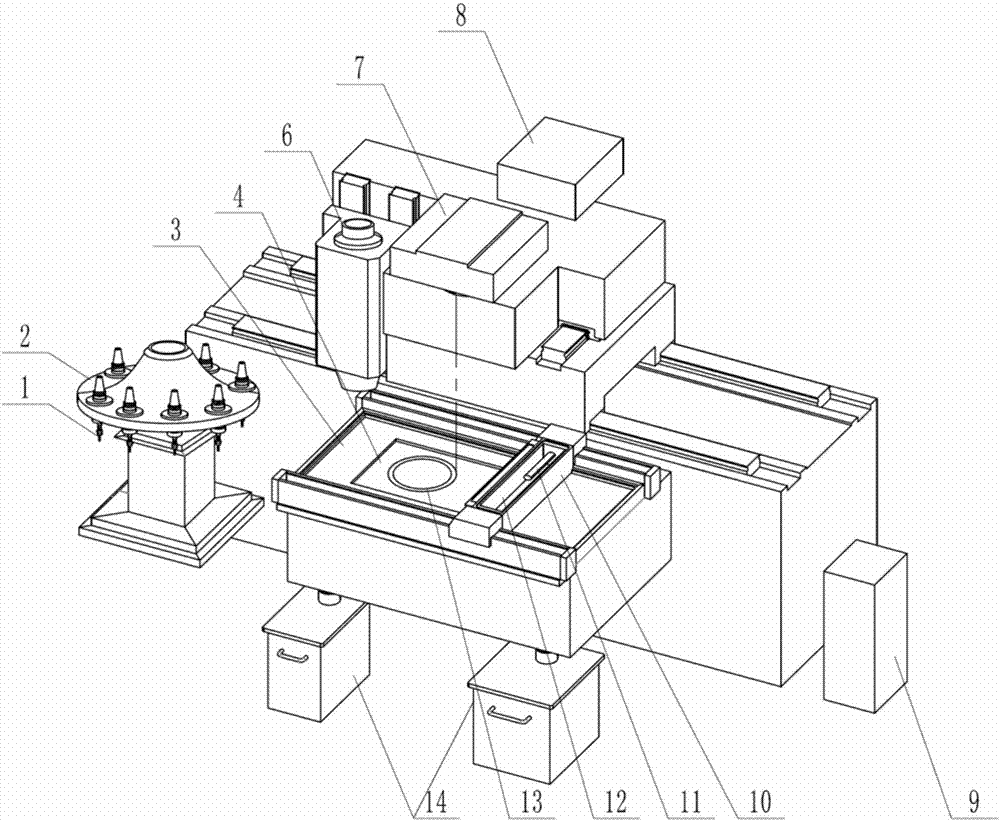

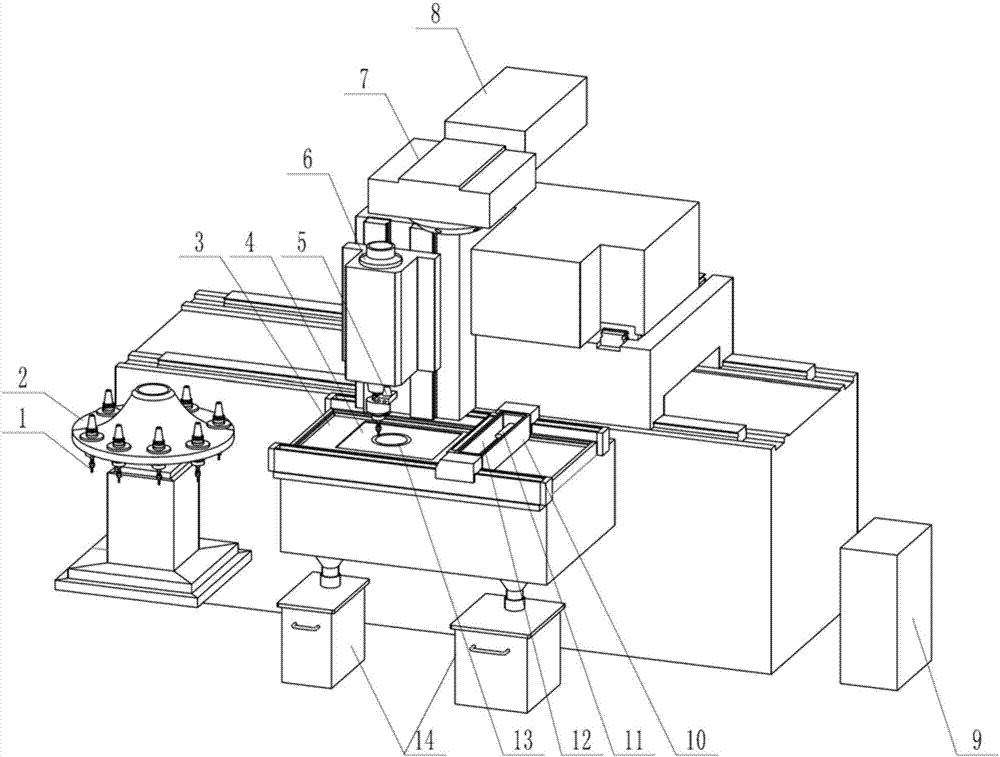

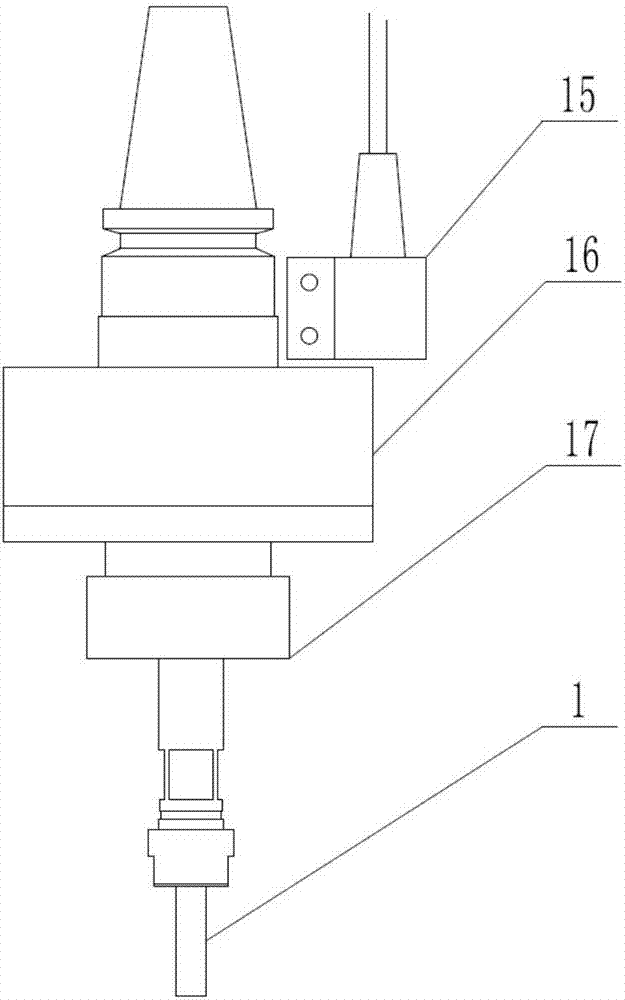

[0037] The specific embodiment of the present invention is shown in the accompanying drawings. The equipment that applies ultrasonic cutting to powder-spreading type additive and subtractive material composite manufacturing includes: tool 1, tool magazine 2, workbench 3, bed, spindle 6, and laser scanning system 7 , a laser generator 8, a powder supply device 9, a powder spreading device, an ultrasonic cutting device 5 and a powder recovery device 14; the workbench 3 is installed in the middle of the front of the bed and arranged horizontally, and there is a molding cavity in the workbench 3 4. The molding cavity 4 can move up and down in the vertical direction, and the substrate can be installed in the molding cavity 4, and the composite manufacturing of adding and subtracting materials is carried out on the substrate; the powder spreading device is installed on the workbench 3 and is located at one end of the workbench 3 ; The laser generator 8 and the laser scanning system 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com