Coal-fired power plant turbulent burner suitable for low-order mixed coal combustion

A swirl burner and mixed coal combustion technology, applied in the burners, burners, combustion methods and other directions of burning powder fuel, can solve the problem of aggravating the overheating temperature of the furnace outlet superheater and slagging, shortening the effective combustion residence time, and boiler flying. The increase of carbon content in ash and other problems can solve the problem of local over-temperature at the outlet, eliminate the phenomenon of hypoxia, and reduce the generation of NOx.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

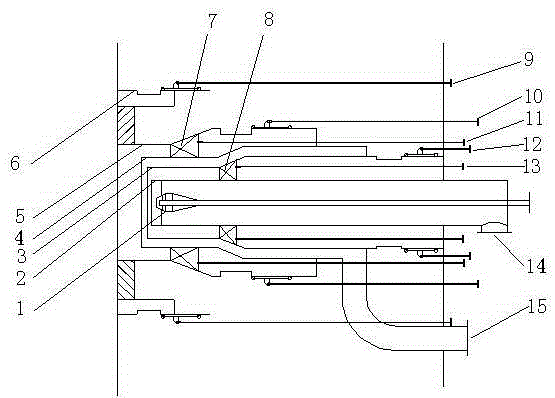

[0023] See attached figure 1 , the present invention includes a cone body 1, an inner primary air casing 2 set on the periphery of the central cone body 1, an inner secondary air casing 3 set on the periphery of the inner primary air casing 2, and an inner secondary air casing set on the inner secondary air casing 3, the outer primary air casing 4 on the periphery and the outer secondary air casing 5 set on the periphery of the outer primary air casing 4; the inner primary air casing 2 is enclosed to form an inner primary air passage, and the inner secondary air casing 3 and the inner primary air casing 2 to form an inner secondary air passage, the inner secondary air casing 3 and the outer primary air casing 4 form an outer primary air passage, and the outer primary air casing 4 and The outer secondary air casing 5 is enclosed to form an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com