Material filling device for plugging high-pressure underground water

A groundwater and high-pressure technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and mining, etc., can solve problems such as difficult control of grout solidification time, uncoagulated concrete structure, pollution of chemical grouting environment, etc., to achieve design Ingenious design, safe and convenient use, and smooth sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

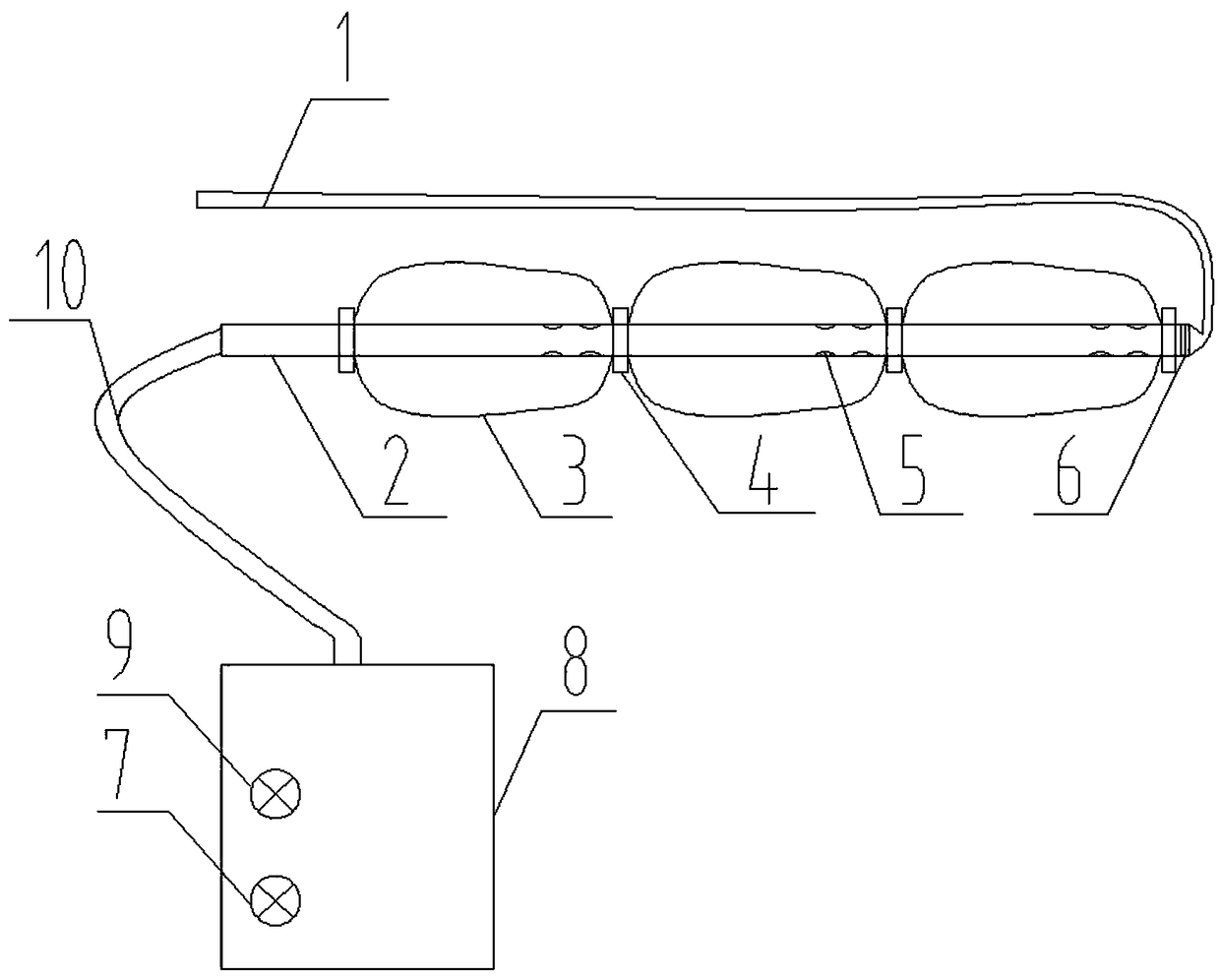

[0022] This embodiment relates to a filling device for blocking high-pressure groundwater, which is realized through the following technical scheme: the injection steel pipe 2 used for pouring concrete is a hollow straight tubular structure, and the injection steel pipe 2 is used for placing in deep-dug wells Or in the exploration well, as the guide pipe for pouring concrete, the length of the injection steel pipe 2 is advisable to be longer than 1 meter in the deep digging well or the exploration well, and the filter sponge 6 for exhaust is fixedly arranged on the injection steel pipe 2, and the filter sponge 6 is in the When blocking the discharge of concrete, the gas in the concrete can be discharged under high-pressure extrusion to improve the sealing performance of the concrete. The exhaust pipe 1 with a metal shell is connected to the exhaust end of the filter sponge 6, and the metal shell prevents the exhaust pipe from leaking. 1 It is difficult to exhaust when it is squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com