Water-soluble briquette adhesive and process applied to briquette production thereof

A water-soluble and adhesive technology, applied in the field of water-soluble briquette adhesive and briquette production technology, can solve the problems of not easy to ignite, reduce fixed carbon content, reduce the amount of adhesive, etc. The effect of low dosage, high fixed carbon content and high product strength

Inactive Publication Date: 2010-08-25

宋邦娟

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the process of coal mining, the amount of coal dust accounts for about 30% of the total coal. The application of coal dust is mostly processed into shaped coal, which is suitable for civil and industrial production. The simplest method of processing shaped coal is Mix with yellow mud to form, use yellow mud as binder, usually 40-60 catties of yellow mud is mixed with every 100 kg of coal dust, which greatly reduces the content of fixed carbon, reduces the fuel value of coal, and increases the ash content. Moreover, the briquette is fragile, not strong, and not suitable for industrial production. Some artificial binders are used to increase the strength of the briquette and reduce the amount of binder. It is better than using yellow mud alone as a binder, and is suitable for industrial briquettes. Production, such as Chinese invention patent 00134771.3 "Industrial Briquette Composite Adhesive", the briquette produced by this binder is suitable for industrial production, but not completely suitable for civilian use. Although the solid briquette has a high combustion value, it is not easy to catch fire

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

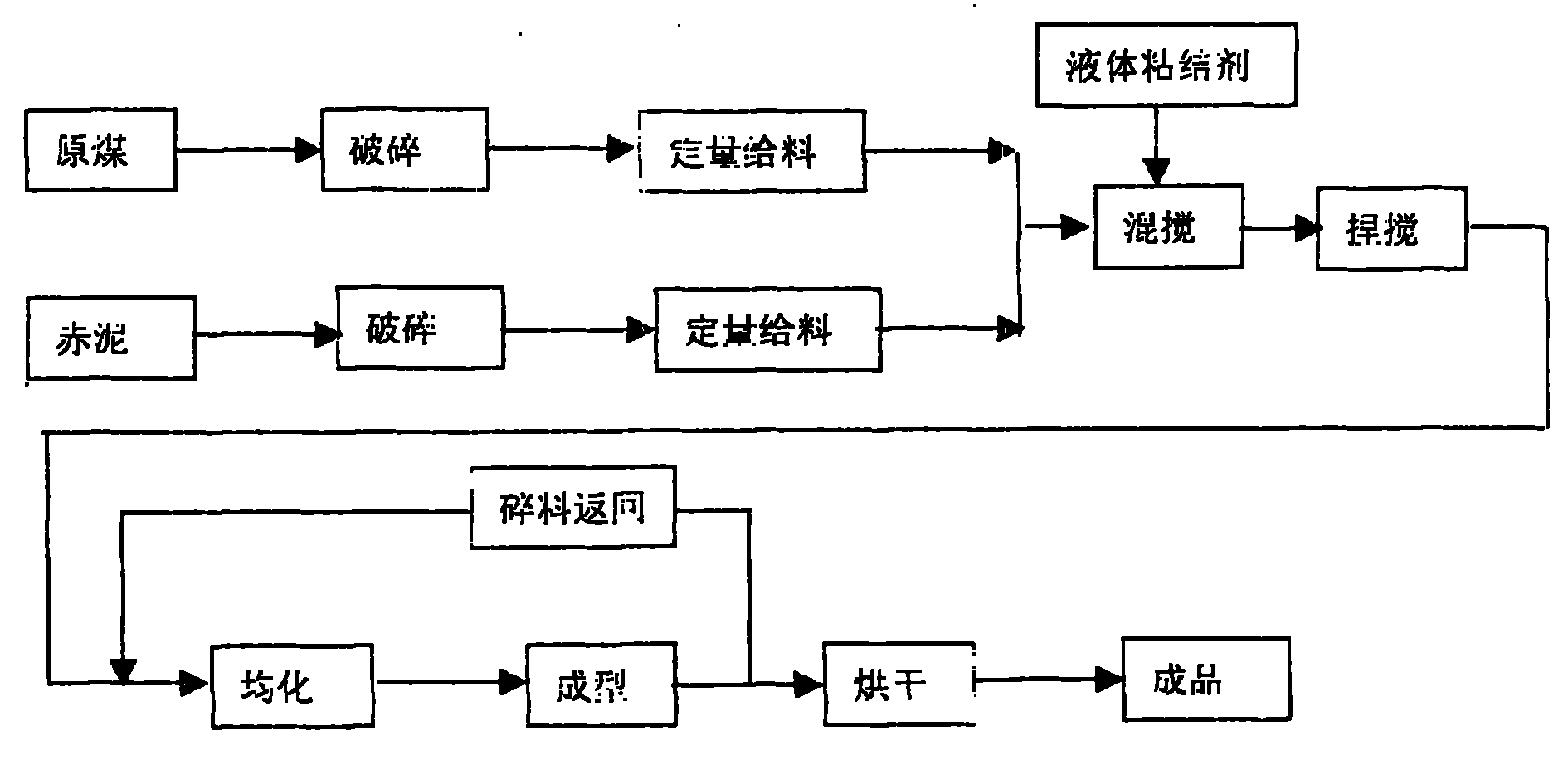

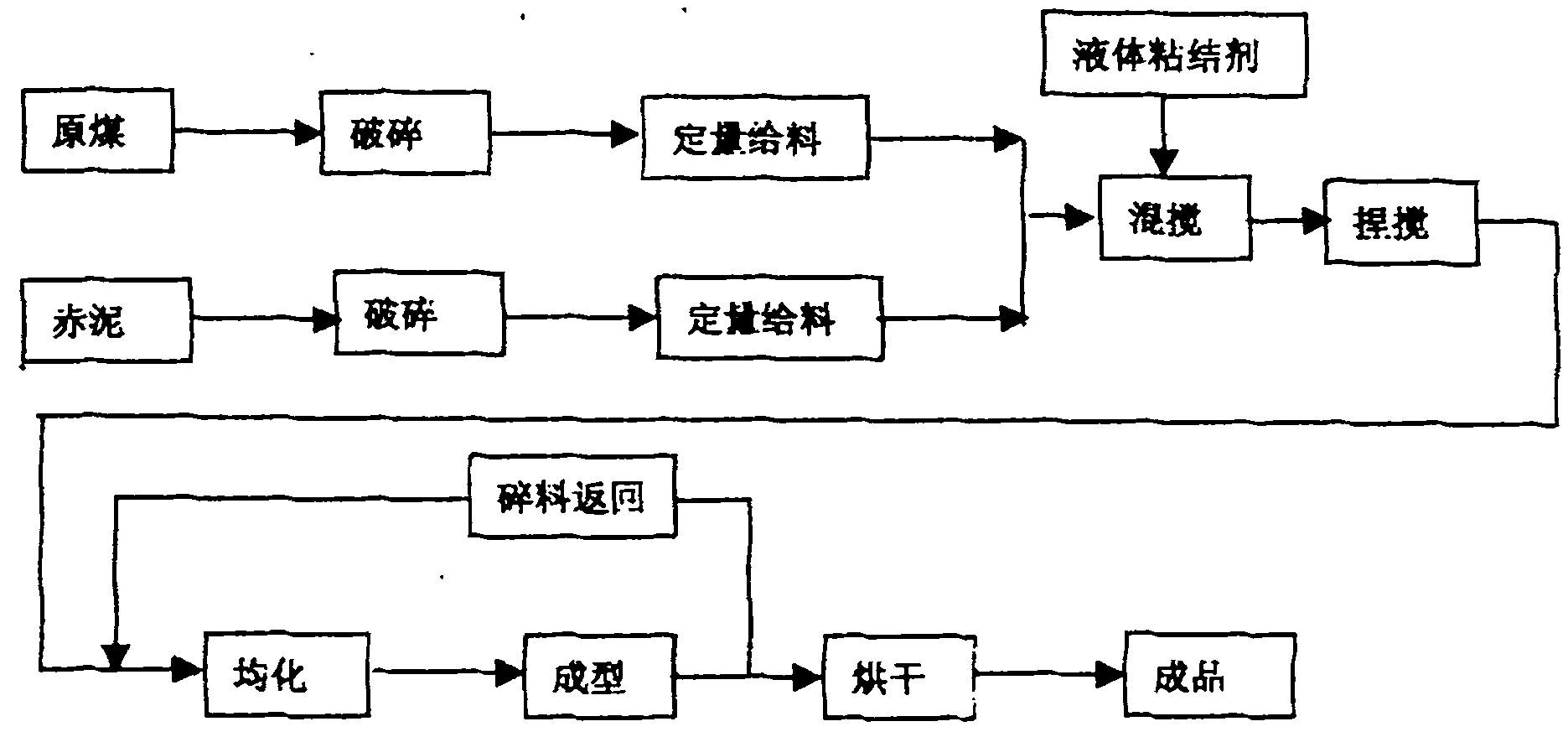

The invention discloses a water-soluble briquette adhesive and a process applied to briquette production thereof and relates to an adhesive for briquette for production industry and civilian use and application thereof. The water-soluble briquette adhesive is combined by organic water-soluble adhesive, inorganic water-soluble adhesive, water-soluble preservative, water-soluble combustion improver and water-soluble sulfur and fluorine removal agent, and the process flow for producing the briquette by utilizing the adhesive is as follows: A. raw material crushing; B. quantitative feeding; C. mixing and stirring; D. pinching and stirring; E. homogenizing; F. molding; and G. drying. The adhesive has little use amount in the briquette production, high adhesive strength, high content of fixed carbon and high fuel value, fire-leading is easy, the firepower is large, and soot smell is difficult to smell.

Description

Water-soluble briquette binder and its application in briquette production technical field The invention relates to an adhesive for producing industrial and civil coal briquettes and its application, in particular to a water-soluble adhesive for briquette coal and its application to the production of briquette coal. Background technique In the process of coal mining, the amount of coal dust accounts for about 30% of the total coal. The application of coal dust is mostly processed into shaped coal, which is suitable for civil and industrial production. The simplest method of processing shaped coal is Mix with yellow mud to form, use yellow mud as binder, usually 40-60 catties of yellow mud is mixed with every 100 kg of coal dust, which greatly reduces the content of fixed carbon, reduces the fuel value of coal, and increases the ash content. Moreover, the briquette is fragile, not strong, and not suitable for industrial production. Some artificial binders are used to increase...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L5/10

Inventor 宋邦娟

Owner 宋邦娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com