Special double-layer temperature-controllable steel frame pleurotus geesteranus greenhouse and thermoregulation fruiting stimulating cultivation method thereof

A technology of pear mushrooms and sheds, which is applied in the field of edible fungi production, can solve the problems of high power consumption, difficult temperature control and temperature adjustment, and unreasonable and scientific problems, so as to achieve improved output and quality, low daily maintenance costs, and easy The effect of administrative operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is an embodiment of the present invention.

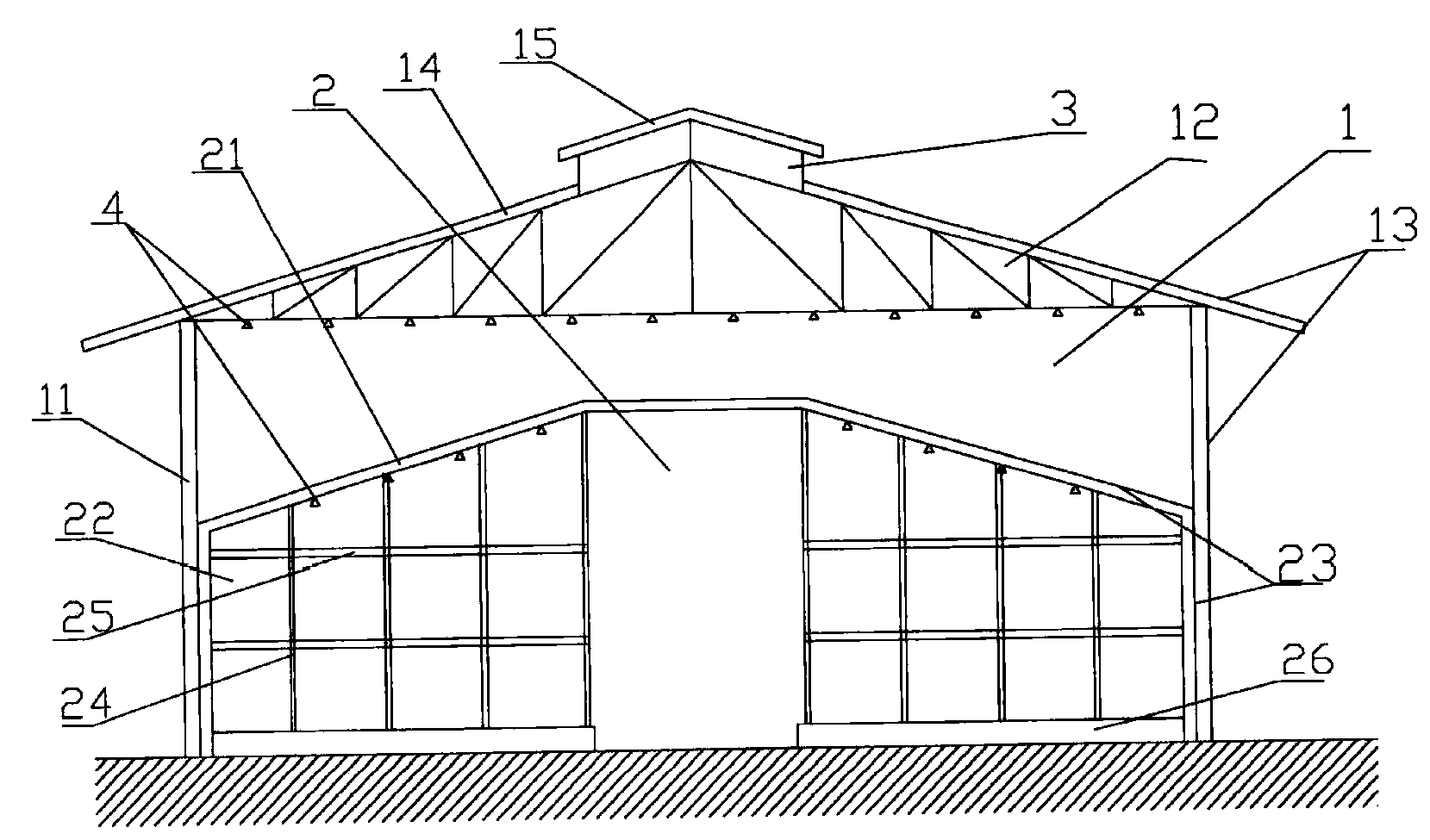

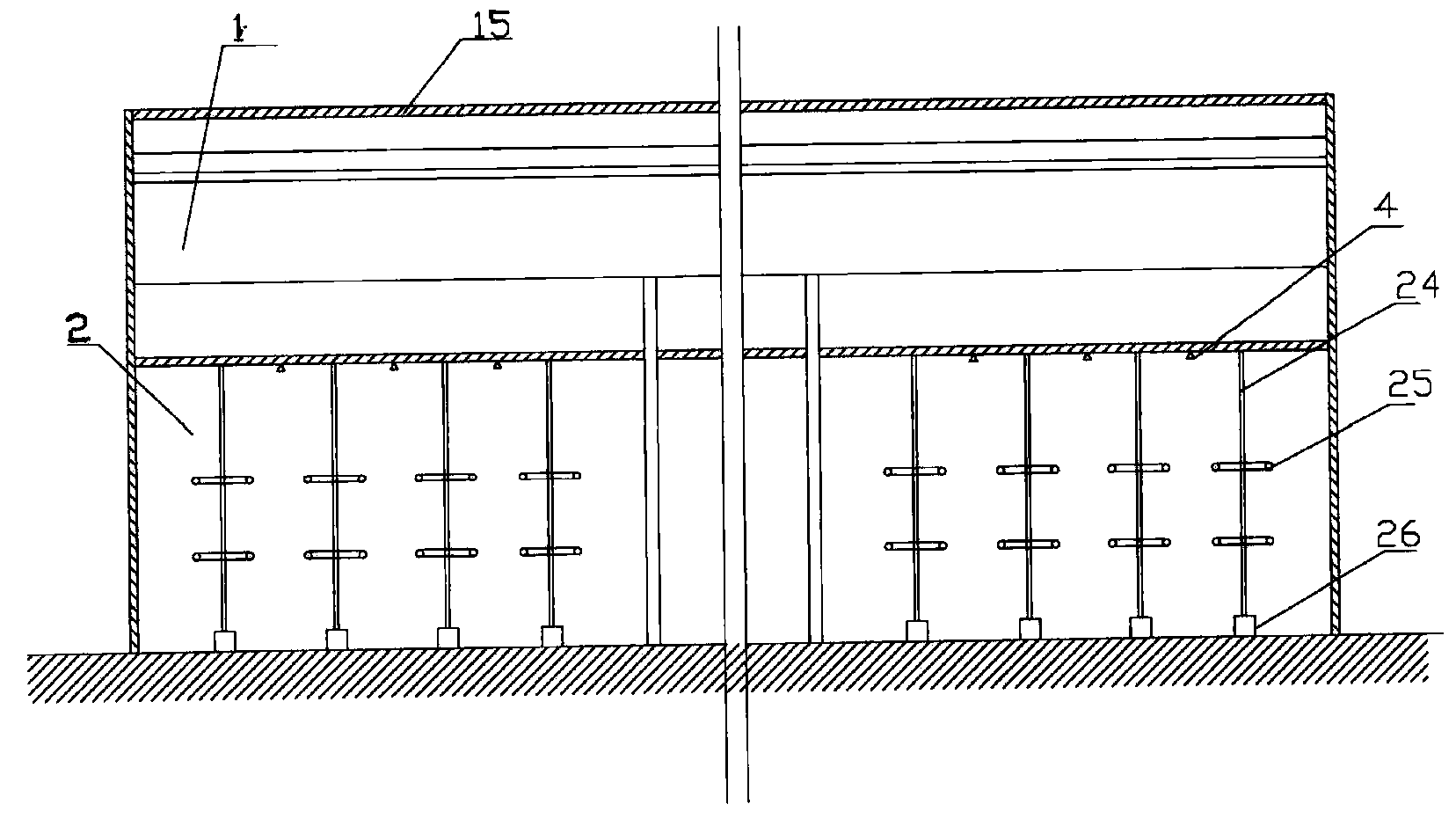

[0039] A double-layer temperature-controlled steel-frame mushroom shed dedicated to rare mushrooms, comprising an outer support shed 1 as the outer layer and an inner shed 2 as the inner layer. The outer support shed 1 includes a shed 11, a shed roof 12 and an outer shed. The surface covering 13, the outer support shed 1 and the inner layer shed 2 located in the inner layer are two independent sealed sheds, and the inner shed 2 is covered in the outer support shed 1, and the shed of the outer support shed 1 There is a vent 3 on the top 11, and the inner shed 2 includes a shed roof 21, a shed 22 and an outer surface covering 23 of the shed, and cooling and moisturizing devices are arranged in the outer shed 1 and the inner shed 4. The roof 11 of the outer support shed is a double-layer structure, and has a roof 14 and a roof 2 15. The roof 14 and the roof 15 are all high in the middle, and the slope roof structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com