Environment-friendly sludge compound briquette fuel and preparation method thereof

A composite molding and environmental-friendly technology, which is applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of molding fuel quality and combustion characteristics maintenance, affecting fuel quality and environmental protection performance, and difficult mixing of sludge and conditioner. Achieve the effects of reducing the cost of chemicals, improving the overall combustion reactivity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

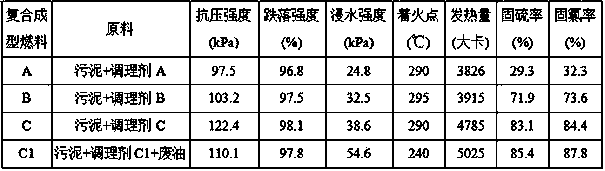

Examples

preparation example Construction

[0022] Preparation method of an environmentally friendly sludge composite briquette fuel

[0023] 1) Sludge dehydration pretreatment: According to the method described in the patent "a method for conditioning and dehydrating sludge with high dryness", the sludge is pretreated to make the moisture content 50-65%;

[0024] 2) Conditioner raw material pretreatment:

[0025] Raw material (1): Biomass powder: at least one of wood chips and straw powder, made by crushing branches and straw to a particle size of less than 0.05mm;

[0026] Raw material (2): shell powder: obtained by crushing discarded shells such as oyster shells, scallops, and clams to a fineness of more than 35 mesh;

[0027] Raw material (3): aluminum powder: commercially available, above 400 mesh;

[0028] 3) Preparation of conditioner:

[0029] Mix shell powder and aluminum powder in step 2) evenly according to the mass ratio of 10: (1~3%), then add biomass powder according to 1%~2% of its weight, mix evenly, ...

Embodiment 1

[0034] 1) Sludge dehydration: Sewage plant sludge is selected as the raw material, and the sludge is pretreated according to the method described in the patent "A Method for Conditioning and Dehydrating Sludge with High Dryness", so that the moisture content is 57.2%;

[0035] 2) Conditioner raw material pretreatment:

[0036] Biomass powder is selected from at least one of wood chips and straw powder, which is obtained by crushing branches and straw to a particle size below 0.05mm;

[0037] Shell powder is obtained by crushing discarded shells such as oyster shells, scallops, and clams to a fineness of more than 35 mesh;

[0038] The aluminum powder is commercially available aluminum powder of more than 400 mesh.

[0039] 3) Preparation of conditioner:

[0040] Conditioning agent A: biomass powder;

[0041] Conditioning agent B: a mixture of biomass powder and shell powder, wherein the biomass powder is 1.5% of the weight of shell powder;

[0042] Conditioning agent C: a ...

Embodiment 2

[0069] 1) Dewatering the sludge: select sewage plant sludge as raw material, and pretreat the sludge according to the method described in the patent "A Method for Conditioning and Dehydrating Sludge with High Dryness" to make the moisture content 50%;

[0070] 2) Conditioner raw material pretreatment:

[0071] Biomass powder is selected from at least one of wood chips and straw powder, which is obtained by crushing branches and straw to a particle size below 0.05mm;

[0072] Shell powder is obtained by crushing discarded shells such as oyster shells, scallops, and clams to a fineness of more than 35 mesh;

[0073] The aluminum powder is commercially available aluminum powder of more than 400 mesh.

[0074] 3) Preparation of conditioner: The conditioner is a mixture of biomass powder, shell powder and aluminum powder. After the shell powder and aluminum powder are mixed evenly at a mass ratio of 10:1, 1% of its weight is added to the biomass powder and mixed. Uniform;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com