Water-soluble briquette adhesive and process applied to briquette production thereof

A water-soluble, adhesive technology, applied in the field of water-soluble briquette adhesive and briquette production, can solve the problems that are not suitable for industrial production, reduce fixed carbon content, increase the strength of briquette, and achieve sulfur removal Complete fluorine removal, high ball forming rate, and high fixed carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, the production of industrial briquette: at first select high-quality anthracite by the technical index of production briquette, then prepare water-soluble briquette binder, the water-soluble briquette binder compounding method is to add organic Add 10 kg of adhesive, add 15 kg of water, heat and stir until completely dissolved, add 50 kg of saturated lime aqueous solution, then add 20 kg of water glass with 45-56 degrees Baume, then add 1 kg of potassium nitrate, and then add sodium fluorosilicate 0.3 kg, add water to 100 kg, stir while adding, until all raw materials are completely dissolved.

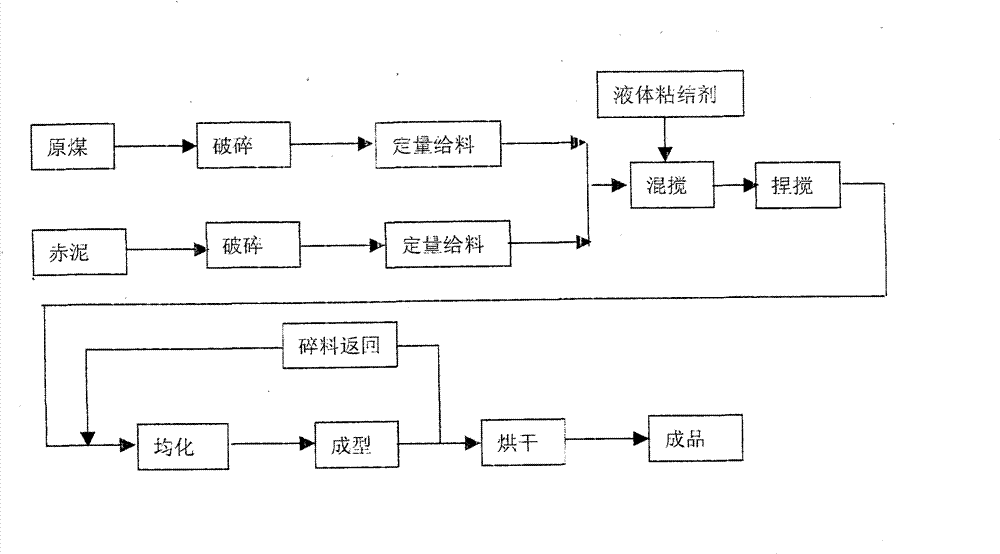

[0046] Then follow the process steps

[0047] A. Raw material crushing: the raw material is anthracite and red mud, the crushing particle size is ≤2.5mm; the sieve residue is 10-20%

[0048] B. Quantitative feeding: the weight ratio of coal to red mud is 100:2;

[0049] C. Mixing: Add 11 kg of water-soluble briquette binder to the mixed powder of 100 kg of coal a...

Embodiment 2

[0056] Embodiment 2, the production of civil briquette

[0057] The production conditions of civil briquettes are not as strict as those of industrial briquettes, and high-quality anthracite is not necessarily selected for raw coal. The preparation of water-soluble binders in the production of civil briquettes: add organic binders to the reaction kettle Add 5 kg of glue, add 20 kg of water, heat and stir until completely dissolved, add 50 kg of saturated lime water, then add 10 kg of water glass with 45-56 degrees Baume, 3 kg of water-soluble combustion aid ammonium nitrate, preservative sodium fluorosilicate 0.2 kg, add water to 100 kg, stir while adding until all raw materials are completely dissolved, then process according to the process steps of Example 1, wherein the difference in step B is that the weight ratio of coal to red mud is 100:8, step C mixing is different in that 10 kg of water-soluble briquette binder is added to 100 kg of mixed powder of coal and red mud fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com