Regenerated coal prepared by oil-containing sludge from oil production field and oil-extraction plant and preparation technology thereof

A production process and refinery technology, which is applied in the field of oil field and refinery oily sludge regeneration coal and its production process, can solve the problems of high operating costs, large energy consumption, and large investment in facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Weigh raw materials (kg) according to the following proportioning ratio:

[0040] Oily sludge, 45% coal, 5% sulfur-fixed substances, 5% adhesives and preservatives.

[0041] Oily sludge 20% Coal 70%

[0042] Sulfur fixation 5% Preservative 5%.

[0043] The coal is crushed to less than 3mm, and ordinary coal with a combustion calorific value of 3000Kcal / Kg-4000Kcal / Kg is selected, preferably 3500Kcal / Kg.

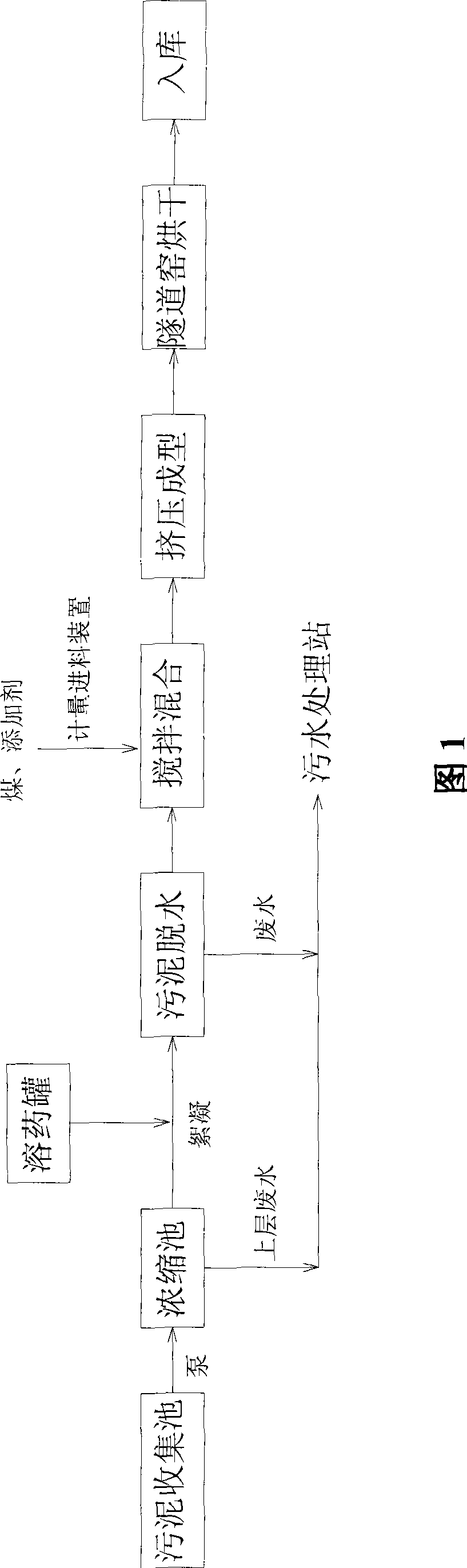

[0044] Please refer to shown in Fig. 1, the oily sludge regenerated coal production process of the present invention is as follows:

[0045] 1) Collect all kinds of oily sludge to the sludge collection tank;

[0046] 2) The oily sludge in the sludge collection tank is lifted to the sludge concentration tank through the sludge lifting pump, and the sludge in the concentration tank is settled by gravity for 2 hours, and the upper wastewater is discharged into the sewage station for treatment;

[0047] 3) Transport the over-concentrated sludge to the pipeline mixer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com