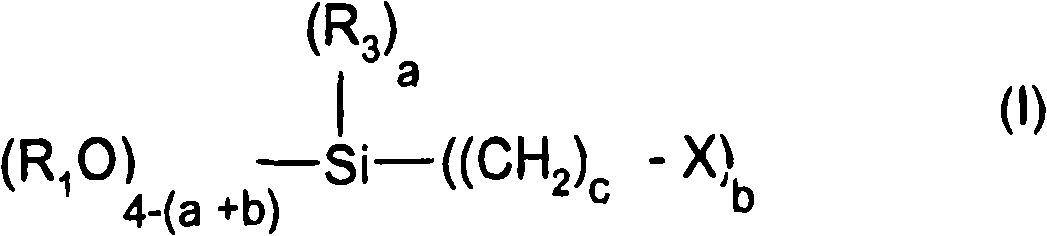

Aqueous emulsion containing organic silicon compound, preparation and use thereof in surface treatment

An organosilicon compound, water-based emulsion technology, applied in impregnating building materials, compound of formula II, preparation of special organosilicon compound, application of emulsion, application field of this emulsion, can solve the problem of reducing the hydrophobic effect of alkoxysilane, penetration Insufficient depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

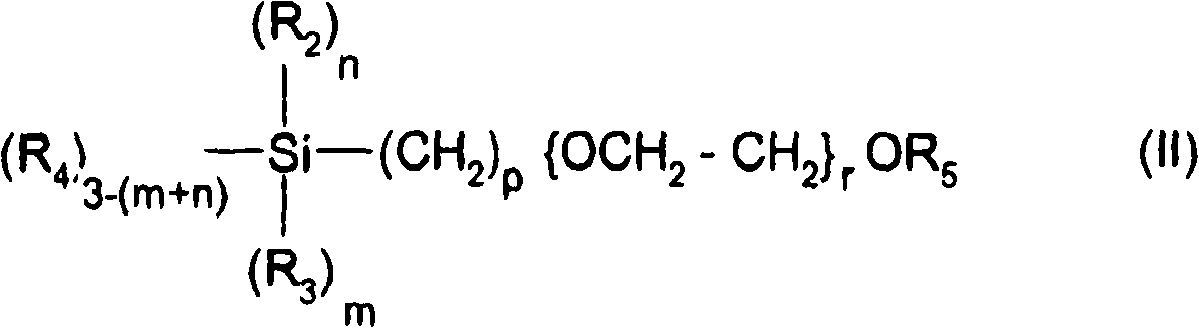

[0105] According to the process of the invention, organosilicon compounds of formula (II) are prepared.

[0106] Usual process:

[0107] The alkoxysilane and surfactant or surfactant mixture are mixed in equimolar amounts or in excess of 0.1-5 mole % of surfactant and the pH is adjusted to about 5 with acid, especially hydrochloric acid.

[0108] The reaction was allowed to proceed by heating to reflux temperature with a continuous decrease in temperature. After the reaction was complete, the alcohol formed was removed under vacuum.

[0109] Yields > 97% are typically obtained. However, it is also possible, according to methods known from the prior art, to prepare said compounds from the corresponding chlorosilane compounds.

[0110] Depending on what proportion of the chlorine atoms should be replaced by surfactant molecules or alkoxy groups, one or more surfactants or alcohols are used in corresponding equimolar amounts or preferably in an excess of 0.1-5 mole %.

[0111...

Embodiment 12

[0120] Likewise, compounds of the type silanes substituted with two surfactant molecules were prepared from the corresponding dichlorosilanes or dialkoxysilanes as described in previous examples.

[0121]

[0122] Table 1.3 includes the following types of compounds prepared,

[0123]

[0124] Table 1.3

[0125]

[0126]

Embodiment 13

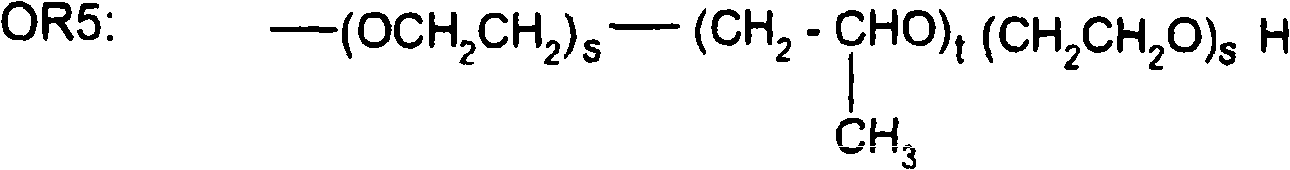

[0128] In this example the preparation of the following types of silicon surfactants is described.

[0129]

[0130] If working in ethanol, the sodium is first dissolved to form sodium ethanolate, followed by the addition of an equimolar amount of surfactant, calculated on alkali metal, followed by heating, preferably to reflux temperature. After about 2 hours, the reaction was complete, it was cooled and 3-chloropropyltriethoxysilane was added dropwise to the clear solution. Then heat to 50-65°C. After 1-2 hours, the reaction is complete at this temperature. After cooling, the precipitated NaCl was filtered and the alcohol was separated by distillation. The reaction is complete.

[0131] In another variation, the surfactant-O-Na-compound is prepared directly by placing the surfactant in an inert organic solvent, such as toluene, followed by the introduction of approximately equimolar amounts of sodium. The reaction was terminated after 1-2 hours at 70°C-80°C. Cool to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com