Novel composite luxury wood-like compression-molded door and manufacturing method

A composite material and manufacturing method technology, applied in the direction of door leaf, window/door, building components, etc., can solve the problems of poor corrosion resistance, thermal insulation performance and sound insulation performance, no fire resistance performance, short service life, etc. Outstanding combustion effect, low oil absorption rate, and the effect of improving oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

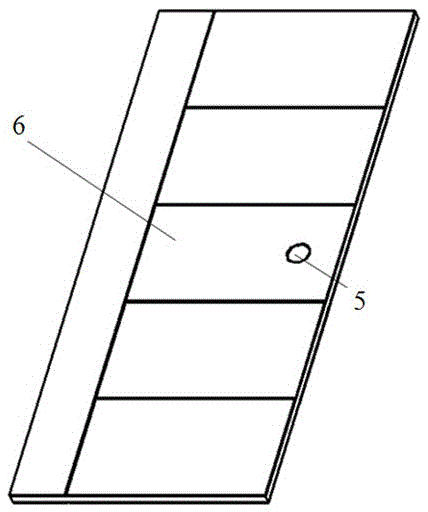

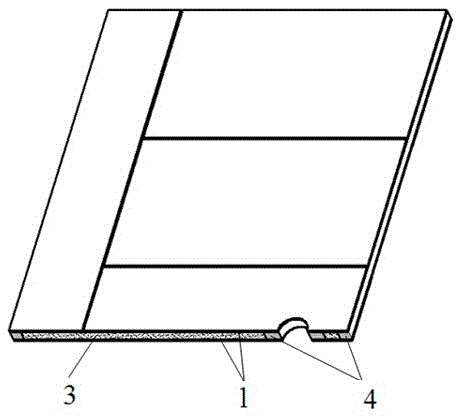

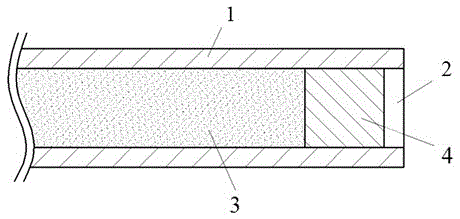

[0039] Embodiment 1: in combination with Figure 1-3 , to further describe the present invention:

[0040] The present invention mentions a novel composite material luxury imitation wood molded door. Its technical solution is to include a composite material door panel 1 made by SMC molding process and a support frame 4 fixed on the periphery of the door panel 1. The inside of the door skin panel 1 is provided with a cavity, and the inside of the cavity is filled with polyurethane foam polymer material 3, and the door skin panel 1 is provided with a lock hole 5, and a solid wood block is inlaid inside the lock hole 5 structure, the surface of the door panel 1 is designed with imitation wood grain texture structure 6.

[0041] The side of the door skin panel 1 is provided with a groove with a depth of 2mm sunken inward, and a PVC edge banding strip 2 is provided inside the groove, which can be used in the assembly and compounding process of the door skin panel, solid wood strip...

Embodiment 2

[0069] Embodiment 2: the difference with embodiment 1 is:

[0070] The door skin plate 1 adopted in the manufacturing process of a novel composite material luxury imitation wood molded door mentioned in the present invention is pressed and formed by using SMC sheet molding compound by molding process, and the described SMC sheet molding compound comprises the following components: Components prepared in weight percent: 25 parts of unsaturated polyester resin, 30 parts of reinforced glass fiber, 35 parts of filler, 1.5 parts of low shrinkage agent, 2 parts of curing agent, 3.5 parts of color paste, 1 part of thickener, 2 parts of molding agent, 4 parts of additives;

[0071] The viscosity of the unsaturated polyester resin is 200mPa.s;

[0072] The reinforced glass fibers are ply rovings with a length of 15 mm;

[0073] The filler is aluminum hydroxide powder with a particle size of 15um;

[0074] The low-shrinkage agent is more than 99% concentration polystyrene;

[0075] ...

Embodiment 3

[0082] Embodiment 3: difference with embodiment 1 is:

[0083] The door skin plate 1 adopted in the manufacturing process of a novel composite material luxury imitation wood molded door mentioned in the present invention is pressed and formed by using SMC sheet molding compound by molding process, and the described SMC sheet molding compound comprises the following components: Components prepared in weight percent: 30 parts of unsaturated polyester resin, 35 parts of reinforced glass fiber, 40 parts of filler, 2 parts of low shrinkage agent, 3 parts of curing agent, 5 parts of color paste, 2 parts of thickener, 3 parts of molding agent, 6 parts of additives;

[0084] The viscosity of the unsaturated polyester resin is 200mPa.s;

[0085] The reinforced glass fibers are ply rovings with a length of 20mm;

[0086] The filler is aluminum hydroxide powder with a particle size of 20um;

[0087] The low-shrinkage agent is more than 99% concentration polystyrene;

[0088] The curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com