High-energy-content amorphous alloy material and preparation method and application thereof

A technology of amorphous alloy and amorphous phase, which is applied in the field of high-energy amorphous alloy materials, and can solve the problem that amorphous alloy strips are easily oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

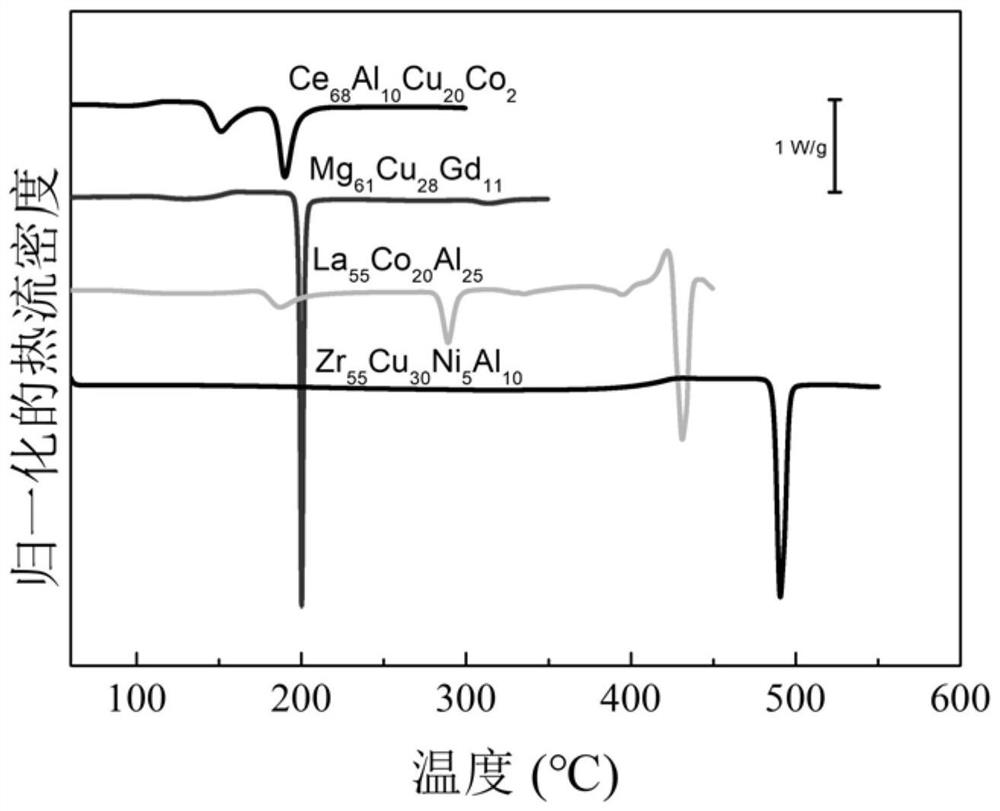

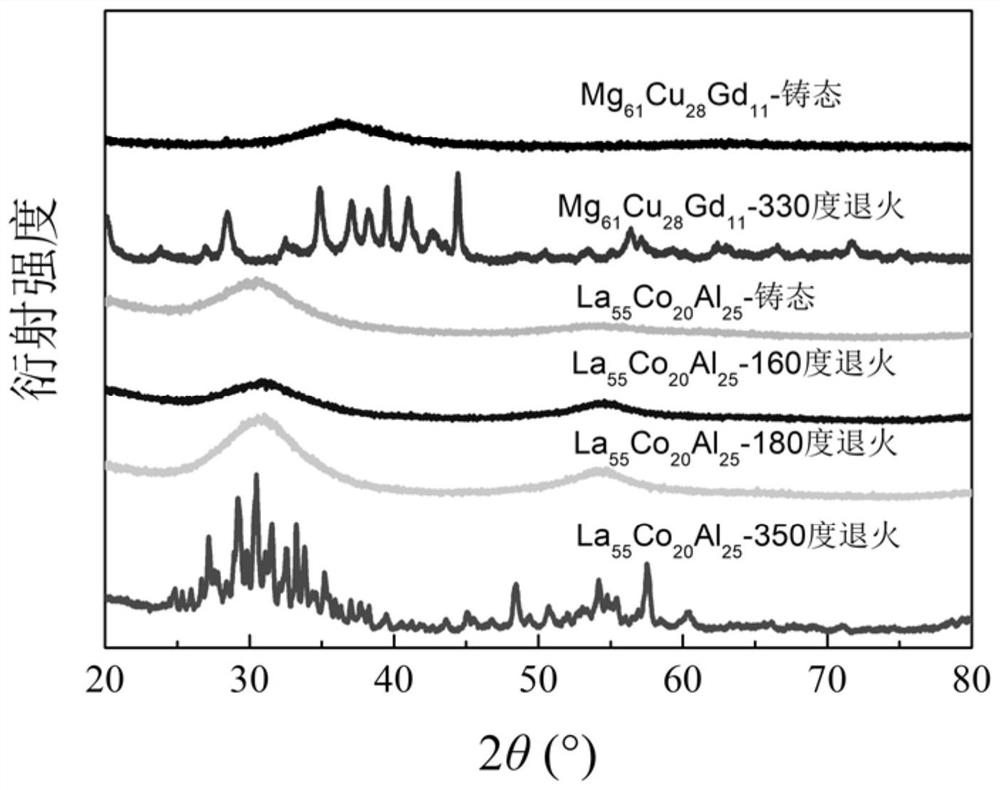

[0110] This embodiment is used to illustrate the preparation of Mg 61 Cu 28 Gd 11 Magnesium-based amorphous strips with high energy content.

[0111] The raw material purity is 99.5wt.% (percentage by weight) Mg, Cu, Gd component is carried out batching according to 61:28:11 (atomic percent); Put into quartz tube and do sealing treatment; Repeated induction melting for many times; after the ingredients are mixed evenly, cool down to obtain the master alloy ingot; crush the ingot and take 5 grams of the scrap and put it into the conical quartz tube of the belt throwing machine; Under the atmosphere, the temperature is raised to 800 degrees Celsius; when the liquid is about to flow, the injection button is quickly pressed, so that the liquid is blown down to the surface of the water-cooled and high-speed rotating (30m / s) copper wheel by high-speed argon gas for spin quenching. Thus, an amorphous alloy strip with a thickness of 50 μm and a length of about 1 meter can be obtain...

Embodiment 2

[0114] This example is used to illustrate the preparation of La 55 co 20 Al 25 Lanthanum-based amorphous alloy filaments with high energy content.

[0115] The La, Co, and Al components whose raw material purity is more than 99.5wt% (weight percent) are dosed according to 55:20:25 (atomic percent); Smelting, more than 5 times until the ingredients are evenly mixed; cooling to obtain master alloy ingots, and then crushing, taking 4g of scraps and putting them into a special glass tube for belt throwing machine; When the liquid is about to flow, it is quickly sprayed onto the surface of a copper roller with convex grooves that is water-cooled and rotates at high speed (line speed 30-50m / s). Thus, lanthanum-based amorphous alloy wires with a diameter of 10-30 μm can be thrown out. The spin speed is fast and the strips are thin.

[0116] Suction-cast the master alloy ingot in an electric arc furnace into a copper mold with an upper diameter of 2mm and a lower diameter of 1.5m...

Embodiment 3

[0119] This embodiment is used to illustrate preparation (Mg 61 Cu 28 Gd 11 ) 0.97 h 0.03 Magnesium-based amorphous alloy powder with high energy content.

[0120] Grind the magnesium-based amorphous strip prepared in Example 1 vigorously in a mortar for 20 minutes, or use a high-speed ball mill (180rpm, 3h) after throwing the strip, and then pass through a 200-mesh sieve to obtain a powder sample with a size of about 10 μm , the material remains amorphous. Such as Figure 6 As shown, the ball-milled amorphous powder has a uniform particle size distribution.

[0121] Use high-pressure argon gas to shock the amorphous alloy fragments, and the fragments gradually become powders in about 2 hours, with a particle size range of 10-200 μm.

[0122] In the high-pressure hydrogen storage device, put 2g of magnesium-based amorphous alloy powder into it, pass through a hydrogen atmosphere of 20mL / min, raise the temperature to 300°C, and keep it for 30min to obtain magnesium-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com