Catalyst for combustion of soot particles in diesel vehicle exhaust, and preparation method thereof

A soot particle and catalyst technology, which is applied in the field of combustion temperature catalyst and its preparation, can solve the problems of high NOx and particulate matter emissions, health hazards, etc., and achieve the effects of fast combustion speed, low production cost, and easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add 0.101g of potassium nitrate KNO to a 200ml beaker 3 , 3.04g cerous nitrate Ce (NO 3 ) 3 ·6H 2 O, 0.537g manganese nitrate Mn(NO 3 ) 2 , and 10ml of deionized water to dissolve, then add 2.732g of citric acid under stirring at room temperature, then add 0.32g of polyethylene glycol (molecular weight 400) after dissolving, after the dropwise addition, heat and stir at 75-80°C until the moisture Evaporates to form a viscous gel. Then the obtained colloid was dried in an air atmosphere at 110°C for 24 hours overnight, and after drying, it was taken out and ground into fine powder, and placed in a muffle furnace for calcination at 600°C for 4 hours, and the composite oxide catalyst K was obtained after the furnace was cooled. 0.1 / C 0.7 mn 0.3 o 2 .

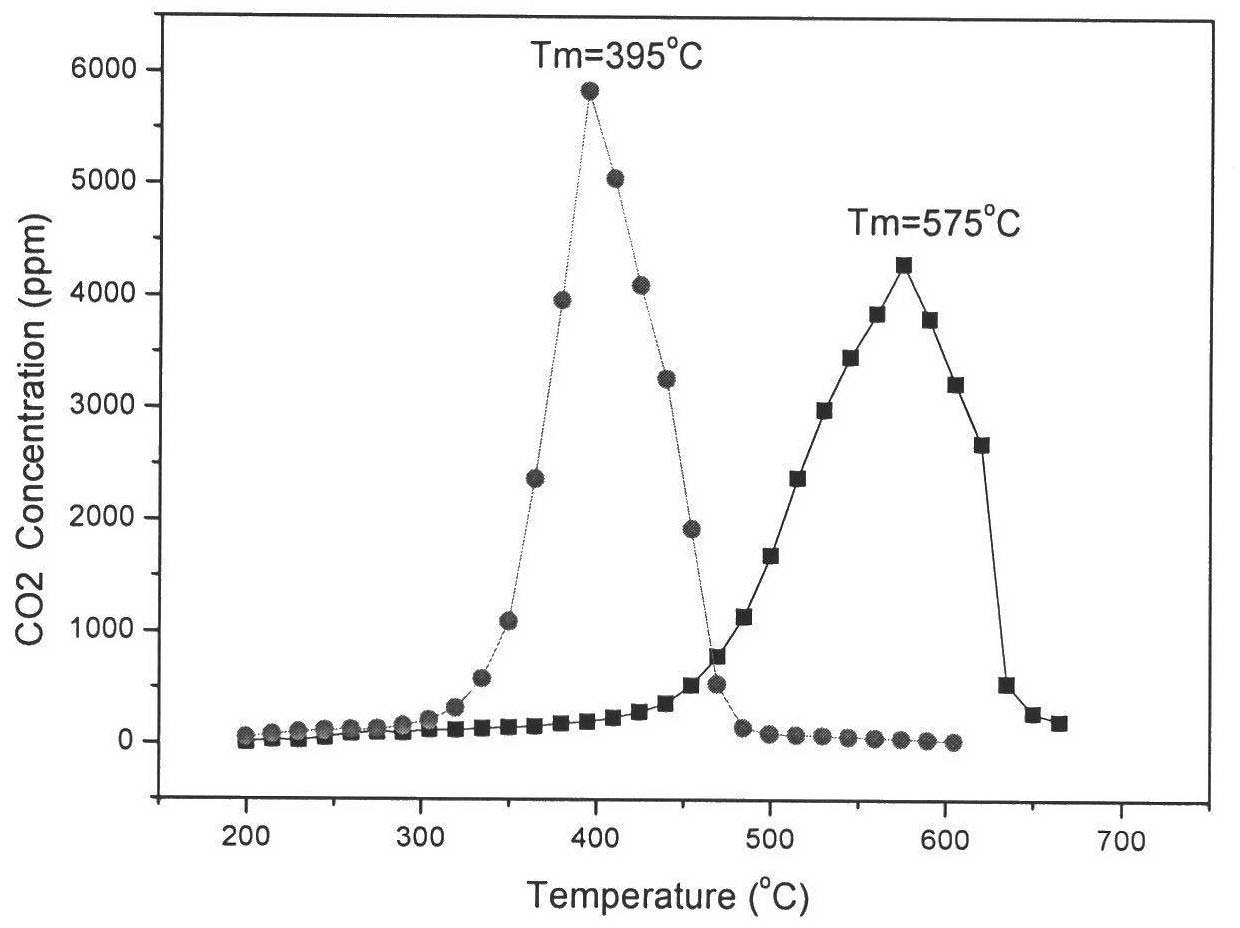

[0015] The catalyst obtained above was mixed with soot (Printex-U, Degussa) at a mass ratio of 10:1 in an agate mortar for 2 min by gently scraping with a spatula to simulate the loose contact conditions between th...

Embodiment 2

[0018] Add 0.202g potassium nitrate KNO to a 200ml beaker 3 , 3.04g cerous nitrate Ce (NO 3 ) 3 ·6H 2 O, 0.537g manganese nitrate Mn(NO 3 ) 2 , and 10ml of deionized water to dissolve, then add 2.732g of citric acid under stirring at room temperature, then add 0.32g of polyethylene glycol (molecular weight 400) after dissolving, after the dropwise addition, heat and stir at 75-80°C until the moisture Evaporates to form a viscous gel. Then the obtained colloid was dried in an air atmosphere at 110°C for 24 hours overnight, after drying, it was taken out and ground into fine powder, and placed in a muffle furnace for calcination at 600°C for 4 hours, and the composite oxide catalyst K was obtained after the furnace was cooled. 0.2 / C 0.7 mn 0.3 o 2 .

[0019] As in Example 1, the catalyst obtained above was mixed with soot (Printex-U, Degussa) at a mass ratio of 10:1 in an agate mortar for 2 min by gently scraping with a spatula to simulate the loose contact conditions ...

Embodiment 3

[0021] Add 0.303g potassium nitrate KNO to a 200ml beaker 3 , 3.04g cerous nitrate Ce (NO 3 ) 3 ·6H 2 O, 0.537g manganese nitrate Mn(NO 3 ) 2 , and 10ml of deionized water to dissolve, then add 2.732g of citric acid under stirring at room temperature, then add 0.32g of polyethylene glycol (molecular weight 400) after dissolving, after the dropwise addition, heat and stir at 75-80°C until the moisture Evaporates to form a viscous colloid. Then the obtained colloid was dried in an air atmosphere at 110°C for 24 hours overnight, and after drying, it was taken out and ground into fine powder, and placed in a muffle furnace for calcination at 600°C for 4 hours, and the composite oxide catalyst K was obtained after the furnace was cooled. 0.3 / C 0.7 mn 0.3 o 2 .

[0022] Measure the combustion situation of soot by the same method of embodiment 1, Tm is 420 ℃ under this catalyst, CO 2 The selectivity was 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com