Catalyst capable of reducing soot particle combustion temperature and preparation method thereof

A technology of combustion temperature and soot particles, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve the effects of easy operation, promotion of soot combustion, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

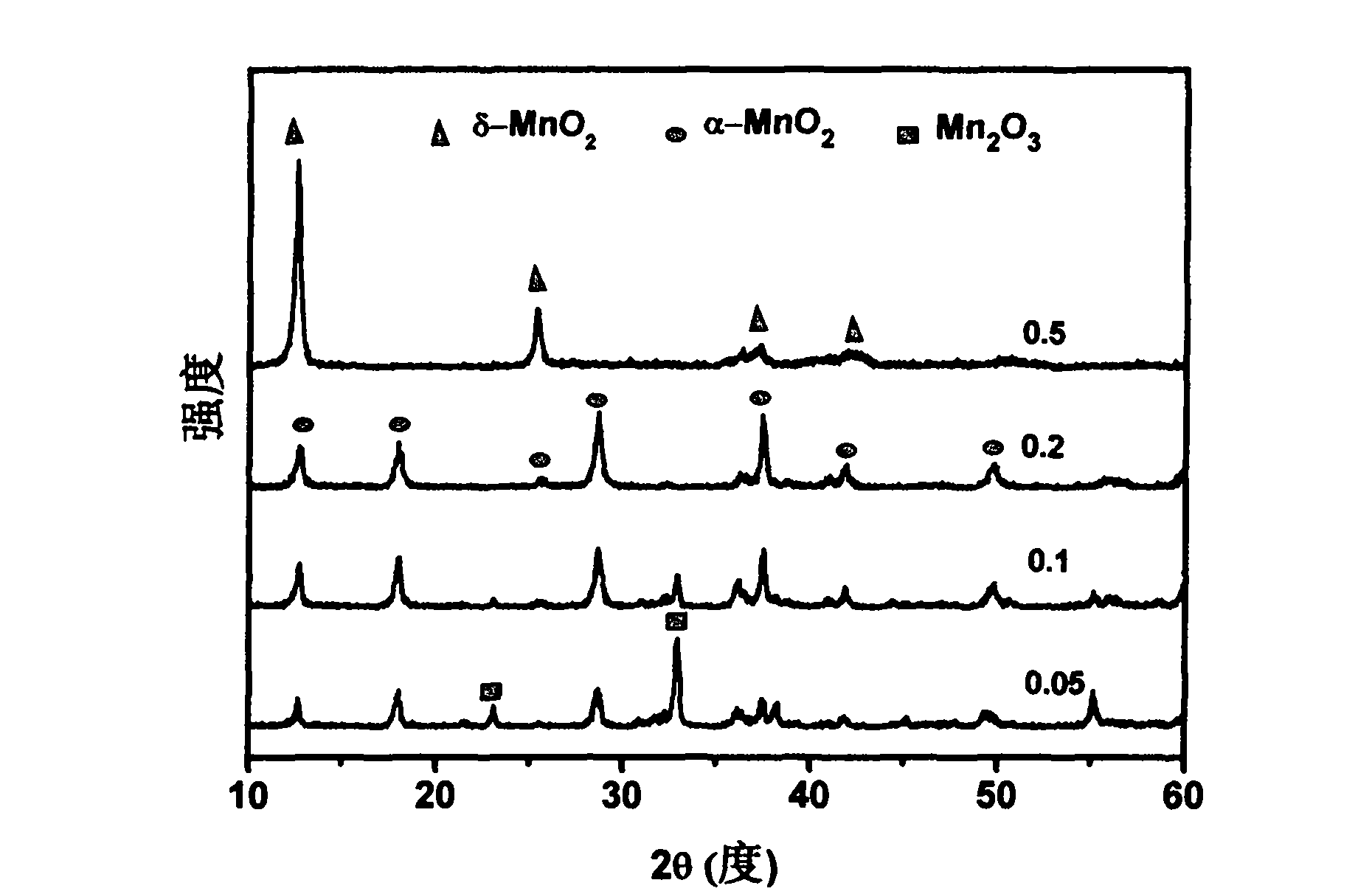

[0014] Weigh 0.005 mol of potassium nitrate and 0.1 mol of manganese acetate, mix them uniformly in a mortar and grind for 10 minutes, then put them into a muffle furnace and bake at 600°C for 5 hours.

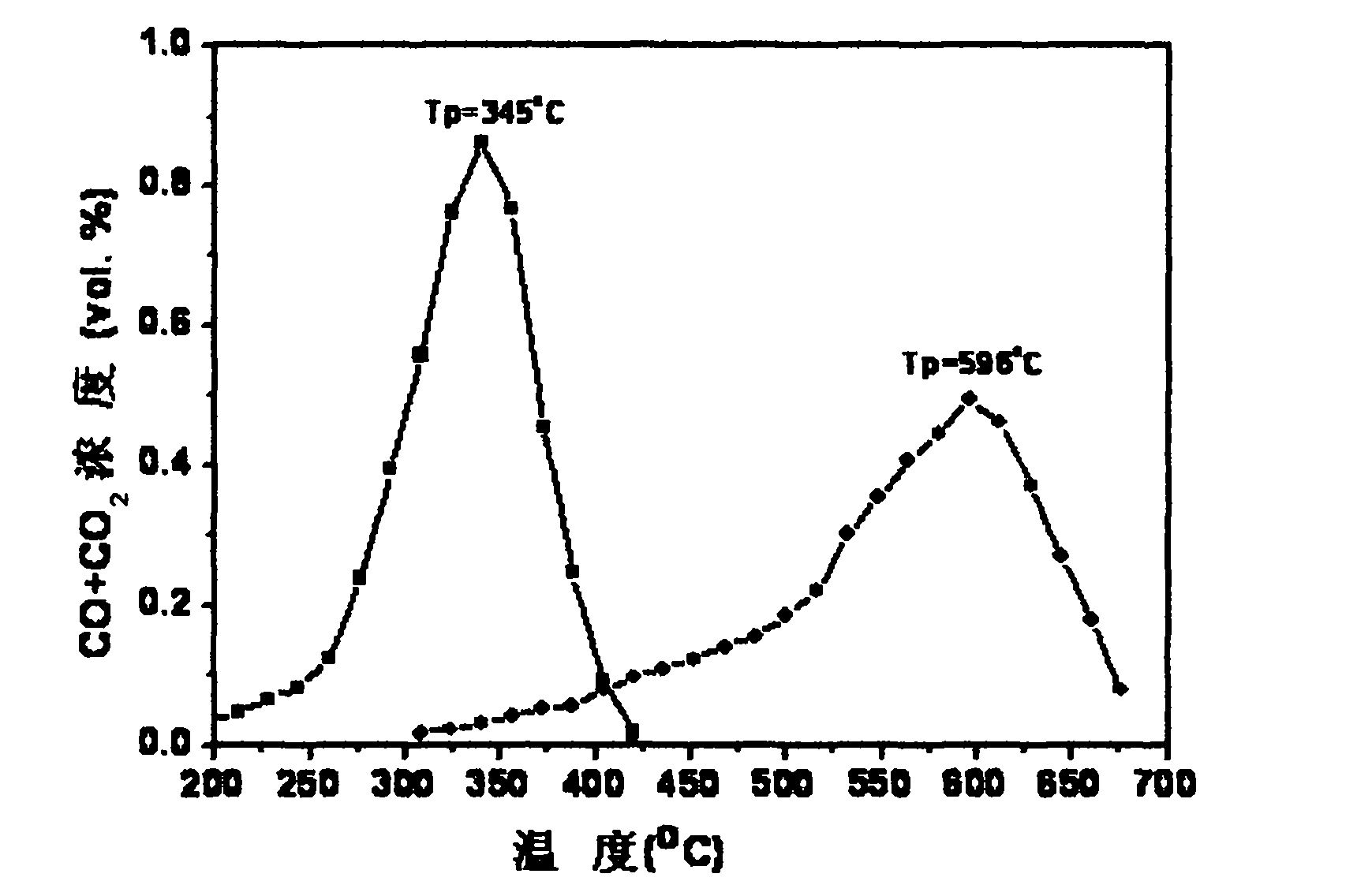

[0015] Mix the catalyst obtained above with the soot particles at a mass ratio of 10:1, stir them evenly in a mortar, and put them into a fixed-bed reaction. At 1000ppmNO+5v%O 2 In the atmosphere of +He, the heating rate is 2°C / min from 200°C until the soot is completely burned out. Chromatographic recording of CO 2 and CO production. CO 2 Corresponding to the temperature at the time when the concentration of CO is the maximum is the temperature T at the time of the highest burning speed of soot p . Under this catalyst T p = 384°C.

Embodiment 2

[0017] Weigh 0.01 mol of potassium nitrate and 0.1 mol of manganese acetate, mix them uniformly in a mortar and grind for 10 minutes, then put them into a muffle furnace and bake at 600°C for 5 hours.

[0018] Measure the combustion situation of soot by embodiment 1, under this catalyst T p = 365°C.

Embodiment 3

[0020] Weigh 0.02 mol of potassium nitrate and 0.1 mol of manganese acetate, mix them uniformly in a mortar and grind for 10 minutes, then put them into a muffle furnace and bake at 600°C for 5 hours.

[0021] Measure the combustion situation of soot by embodiment 1, under this catalyst T p = 345°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com