Low-carbon energy-saving gas

A fuel and raw material technology, applied in the field of industrial or civil gas fuel, can solve the problems of high cost, environmental pollution, hidden safety hazards, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The low-carbon fuel is composed of raw materials mixed in the following weight ratios: dimethyl ether 60-80, refined methanol 20-36, additives 1-3, nano-nickel liquid suspension 0-0.2; the above-mentioned additives are composed of raw materials in the following weight ratios : Propyl ether 15-25, ferrocene 0.3-0.7, naphthenate 1-2, anti-gelling agent 1-3, preservative 1-2, dispersant 1.5-2.5, stabilizer 8-12, anti-aggregation 1.5-2.5, lanthanum isozincate 1-1.4, nano-nickel liquid suspension 0.2-0.4.

[0018] The naphthenic acid salts are lanthanum and manganese salts of naphthenic acid.

[0019] Described anti-gelling agent is: T501.

[0020] Described preservative is: BR-903.

[0021] Described dispersant is: T151.

[0022] The stabilizer is: 3:3:3 oil mixture.

[0023] The aggregation prevention is: dimethylsiloxane.

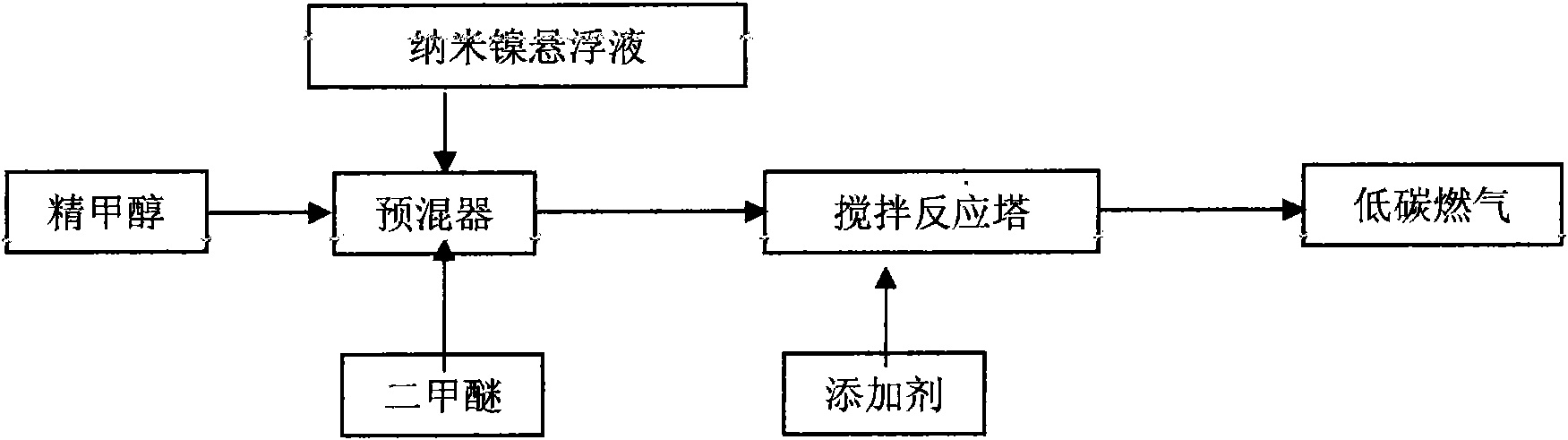

[0024] refer to figure 1 , the manufacturing method of the above-mentioned low-carbon fuel is: when the refined methanol enters the pre-mixer, d...

Embodiment 2

[0026] The low-carbon fuel is composed of raw materials in the following weight ratios: dimethyl ether 68-72, refined methanol 26-30, additives 1.8-2.2, nano-nickel liquid suspension 0.08-0.12; the above additives are composed of raw materials in the following weight ratios : Propyl ether 18-22, ferrocene 0.4-0.6, naphthenate 1.3-1.7, anti-gelling agent 1.8-2.2, preservative 1.3-1.7, dispersant 1.8-2.2, stabilizer 9-11, anti-aggregation 1.8-2.2, lanthanum isozincate 1.1-1.3, nano-nickel liquid suspension 0.25-0.35.

[0027] The manufacturing method and ingredients of the low-carbon fuel in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0029] The low-carbon fuel is composed of raw materials mixed in the following weight ratio: dimethyl ether 70, refined methanol 28, additive 2, nano-nickel liquid suspension 0.1; the above additives are composed of raw materials in the following weight ratio: propyl ether 20, ferrocene 0.5, naphthenate 1.5, anti-gelling agent 2, preservative 1.5, dispersant 2, stabilizer 10, aggregation inhibitor 2, lanthanum isozincate 1.2, nano-nickel liquid suspension 0.3.

[0030] The manufacturing method and ingredients of the low-carbon fuel in this embodiment are the same as those in Embodiment 1.

[0031] The present invention establishes a new raw material direction. Since oil can be pumped out, coal can be dug up, and biomass resources are inexhaustible, we choose the third direction to obtain resources, that is, the raw material of low-carbon gas can be natural gas, coal, or biomass. Matter is inexhaustible, as long as there is the sun, there will be biomass, and there will be low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com