Two-stage flame generator

A generator and flame technology, applied in the burner, combustion ignition, combustion method, etc., can solve the problems of increasing the power adjustment range of the flame generator, and achieve the effects of significant energy saving, reduced consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

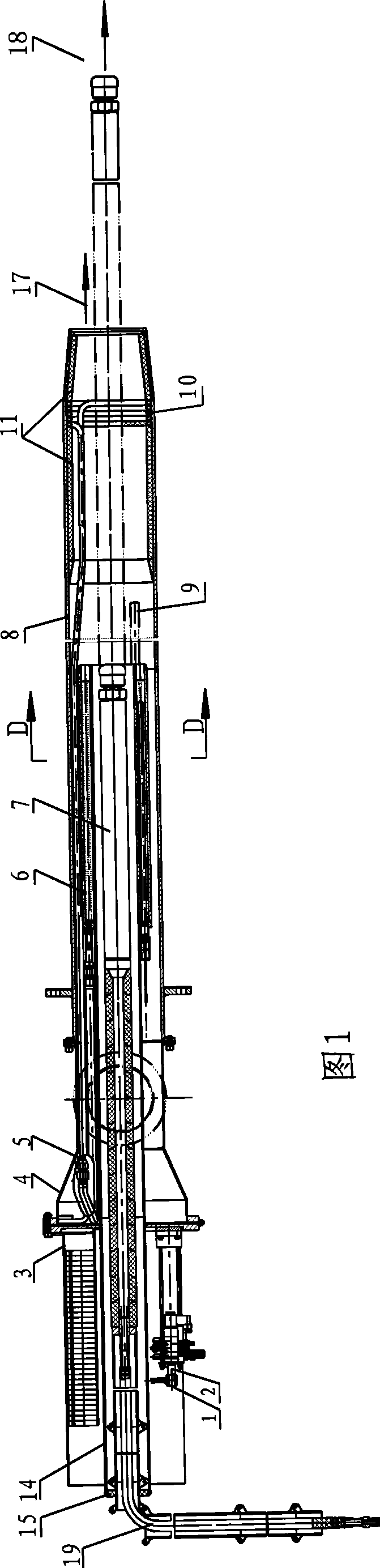

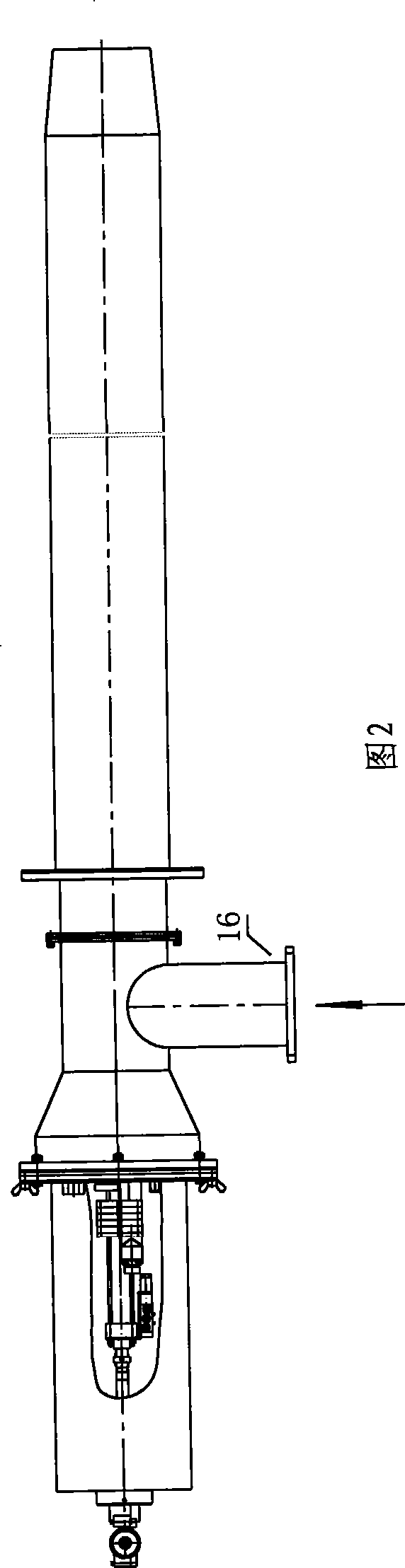

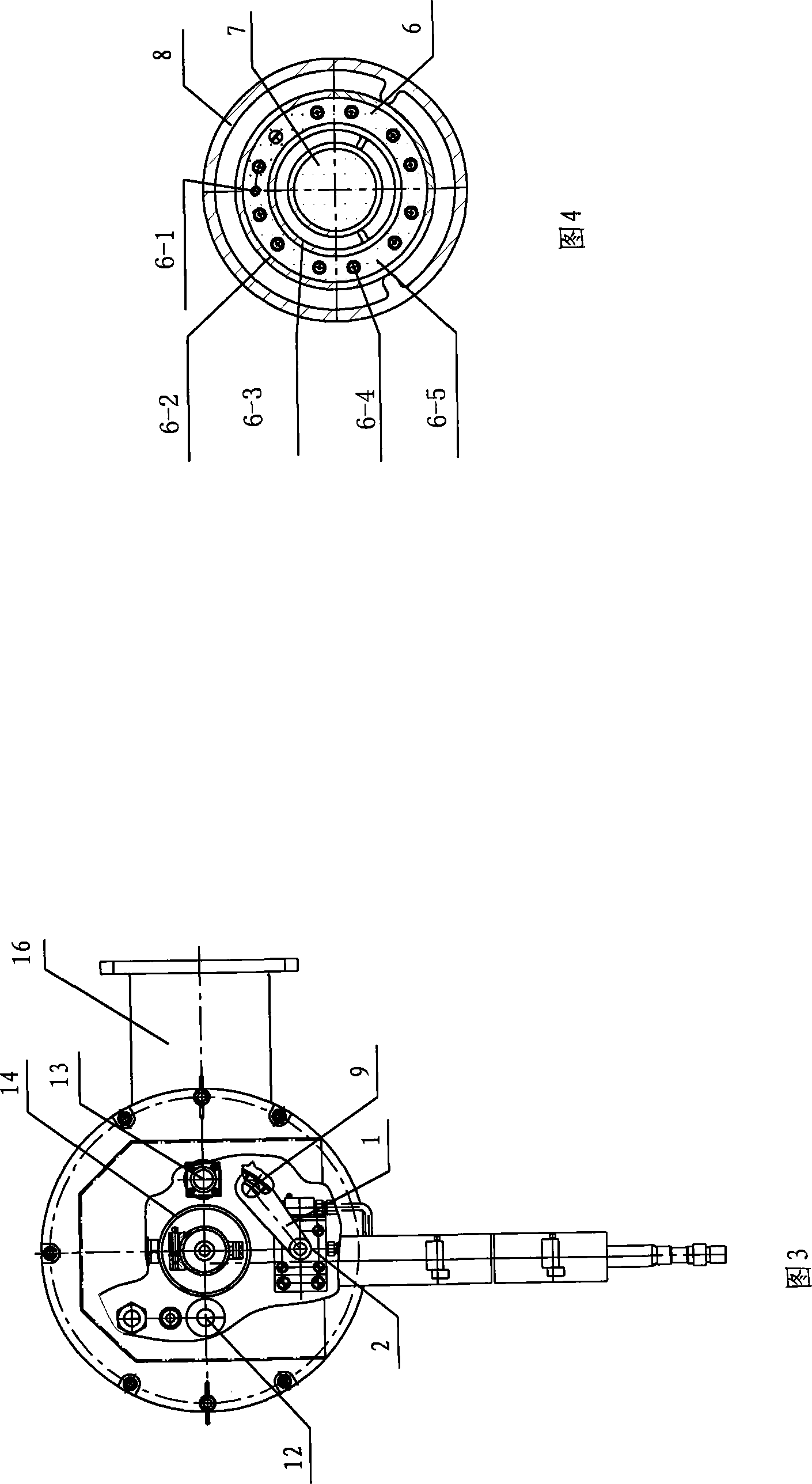

[0023] The structure of the novel flame generator of the present invention is shown in Figure 1, and it is mainly made up of following seven parts components and parts: 1, oil inlet pipeline; 2, vaporizer; ; 4. Air distribution device: including air distribution tube, preheating ring, heat insulation cover, etc.; 5. Detection mechanism: including fire viewing hole, visible light flame detection probe, etc.; , ignition gun and other pieces; seven, the second-stage flame generator. The shell is composed of rear hood, middle bellows and front air distribution tube. The first-stage flame generator is composed of an ignition gun, an oil inlet pipe and a vaporizer inside the shell. The second-stage flame generator is axially and concentrically set in the central ventilator of the first-stage flame generator.

[0024] In Fig. 1 and Fig. 2: 1, connecting plate, 2, cylinder, 3, hood, 4, bellows, 5, oil inlet pipe, 6, carburetor, 7, second-stage flame generator, 8, air distribution cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com