Gas burner capable of adjusting premix

A gas burner and premixing technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of unstable gas volume, inability to meet the requirements of the process curve, and difficult process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

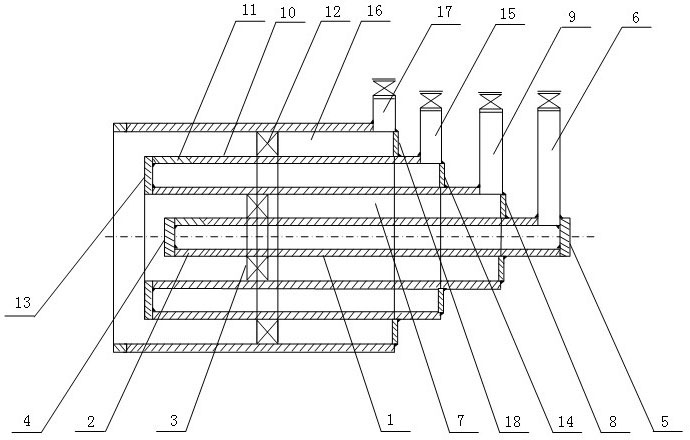

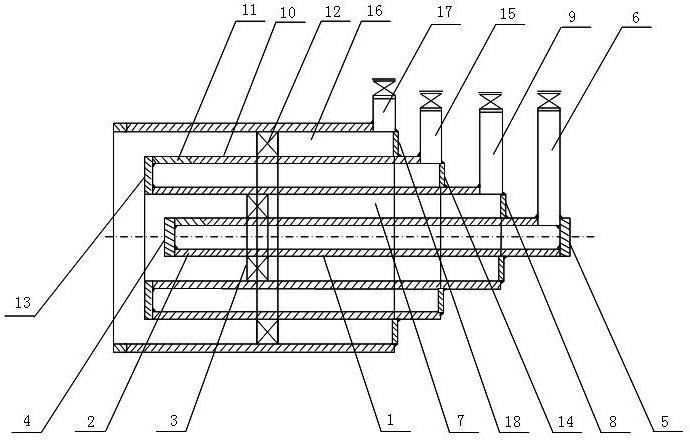

[0008] Five, specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

[0009] The small nozzle gas pipe 1 of this gas burner is designed according to the minimum heat required for implementing the furnace. The small nozzle gas pipe 1 is located at the center of the gas burner, and the annular space between the small nozzle gas pipe 1 and the large nozzle gas pipe 10 is an air channel 7 . Small nozzle gas pipe 1 front end side circumferentially opens gas injection hole 2, and front end welds blocking plate 4, and rear end welds blocking plate 5, and the rear end side is connected with gas by the gas inlet pipe 6 welded therewith. A gas control valve is installed on the gas inlet pipe 6, which is used to adjust and control the amount of gas entering the small nozzle gas pipe 1. The air swirl sheet 3 is set on the outside of the small nozzle gas pipe 1, the height of the air swirl sheet 3 is slightly smaller than the i...

Embodiment 1

[0014] The present invention is used in the old factory of Puyang Pu Nai Functional Materials Co., Ltd. 1# kiln furnace with 1.6 million kcal, the natural gas pressure is 8Pa, and one furnace is provided with 8 burners. According to the furnace type, heat required by the furnace, and natural gas pressure, the amount of natural gas is distributed to the small nozzle gas pipe 1 and the large nozzle gas pipe 10 in the 8 burners. The amount of natural gas ejected from the small-nozzle gas pipe 1 is 0.5-5 m3 / hour, and the amount of natural gas ejected from the large-nozzle gas pipe 10 is 5-25 m3 / hour. After processing and assembling, the gas pipe 1 is ignited. Raise the temperature from 100°C to 400°C according to the heating curve, switch to the large nozzle gas pipe 10 after keeping the temperature at 400°C for 8 hours, slowly raise the temperature to 1100°C according to the heating curve 500-600-700-800-900-1100°C, and then keep the temperature for 4 After 1 hour, continue to he...

Embodiment 2

[0016] The furnace used in Puyang Glass Factory is 1.6 million kcal, one burner, and the natural gas pressure is 0.2Mpa. It is designed, processed, installed, ignited and operated according to the furnace type and the heat required by the furnace. The natural gas injection volume per hour is 187 m3 / hour. The original natural gas injection volume is 200 m3 / hour, saving energy by 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com