Multifunctional combined type lifting framework for installing large scale electrical power unit

A kind of power equipment and multi-functional technology, which is applied in the field of lifting steel structure for large-scale equipment installation and construction, can solve the problems of poor safety and low efficiency, achieve the effect of small impact, high safety, and meet the requirements of road transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

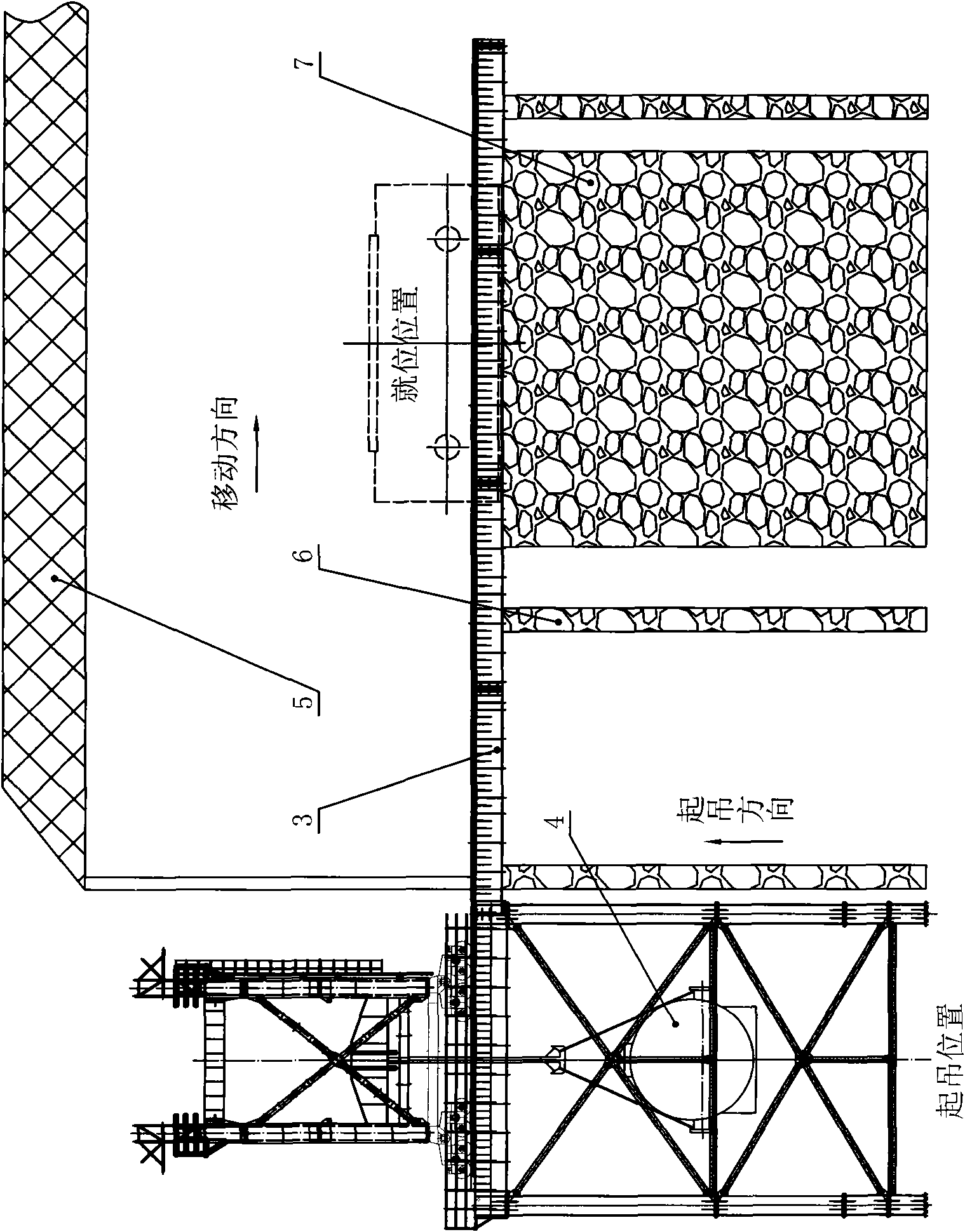

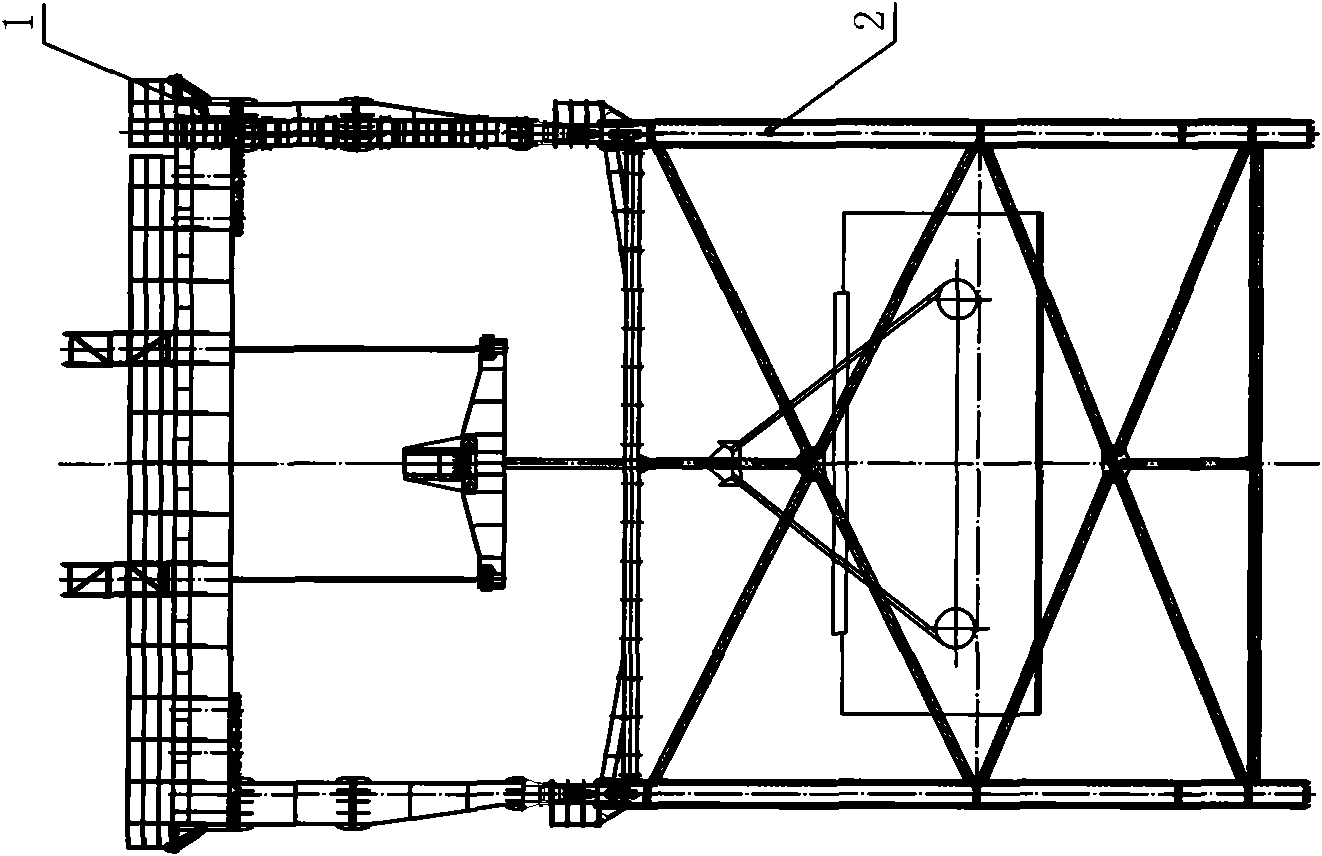

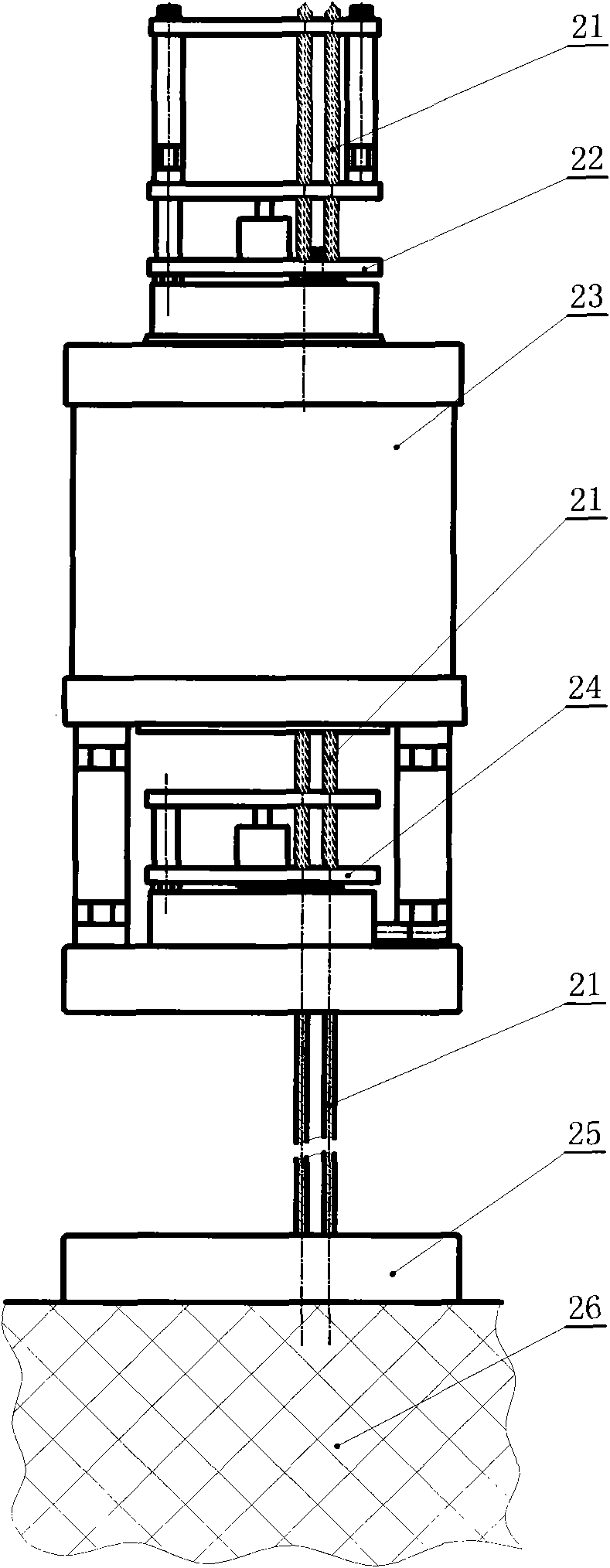

[0052] FIG. 1 is a schematic diagram of the composition and structure of the multifunctional combined hoisting frame of the present invention and a schematic diagram of hoisting the stator. The multi-functional combined hoisting frame includes four parts: mobile frame 1, fixed frame 2, track beam 3 and auxiliary components. The functions of each part are as follows:

[0053] 1) The moving frame 1 is provided with the installation position of the cable-type hydraulic lifting device to realize the horizontal movement of the suspended member 4 (the vertical lifting of the suspended member 4 is realized by the cable-type hydraulic lifting device);

[0054] 2) The fixed frame 2 is installed on the outer side of the end of the turbine room 5 (or on the hanging object hole inside the turbine room) to provide support for the movable frame 1;

[0055] 3) The rail beam 3 is erected on the upright column 6 of the steam engine room to provide a walking track for the mobile frame 1;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com