Optical fiber preform and preparation method thereof

An optical fiber preform and core rod technology, which is used in cladding optical fibers, glass manufacturing equipment, optics, etc., can solve the problem of simultaneous optical and optical simultaneous interpretation of base station construction at the access layer, the attenuation coefficient of optical fiber preforms is not ideal, and the bending resistance of optical fibers Preform difficulties and other problems, to achieve the effect of improving transmission quality, small attenuation coefficient, and small attenuation amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

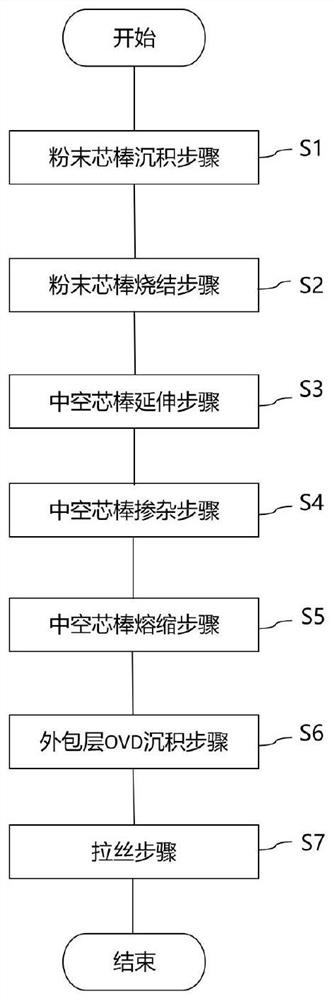

[0059] In this embodiment, the preparation method of the optical fiber preform is described in detail.

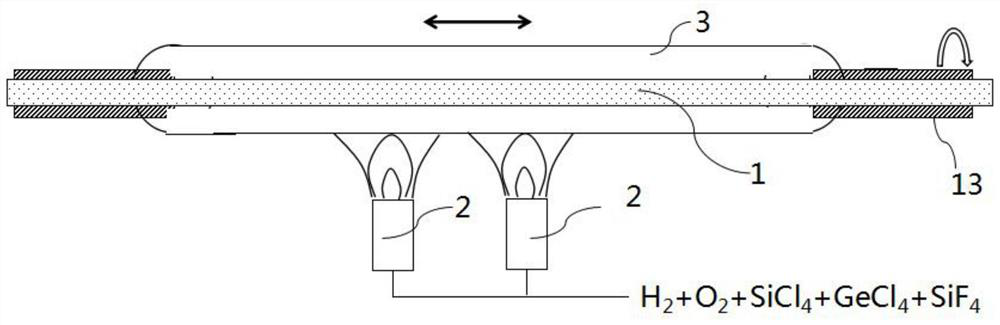

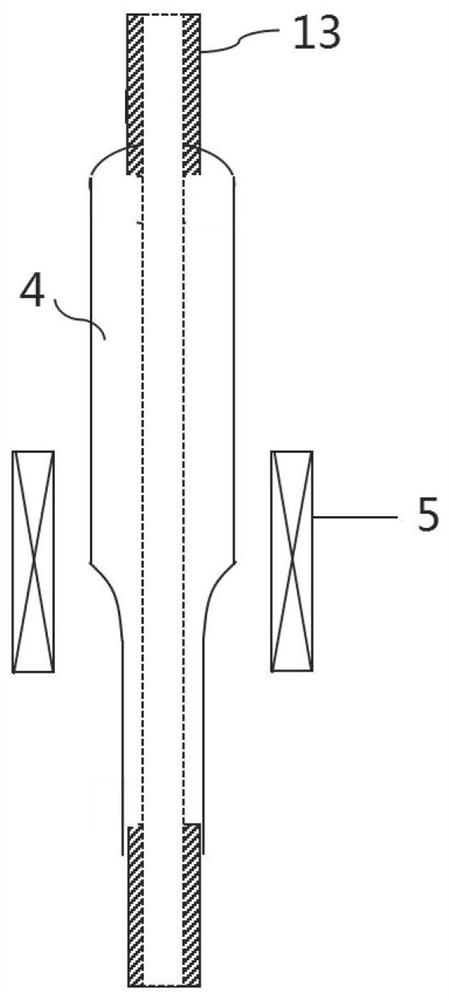

[0060]Step S1, powder mandrel deposition process: fix a ceramic rod with a diameter of 20mm on the external vapor deposition equipment, the ceramic rod moves axially at a speed of 180mm / min, and rotates around the axis at a speed of 30rpm, and the blowtorch is located under the ceramic rod , the nozzle of the blowtorch is 150mm away from the outer surface of the ceramic rod, and then the four gases are fed through different pipes according to the flow rate of hydrogen 80L / min, oxygen 40L / min, silicon tetrachloride 50g / min, and germanium tetrachloride 400mg / min. Blowtorch, hydrogen, oxygen, silicon tetrachloride and germanium tetrachloride burn at the blowtorch port to produce the first deposit, the first deposit is deposited on the outer surface of the ceramic rod, after measuring the thickness of the first deposit layer reaches 30mm, Stop feeding germanium tetrachloride, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com