Tensioner for parallel steel strand stay cables and construction method thereof

A cable-stayed cable tensioner and parallel steel strand technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of inconvenient construction operation, increased construction difficulty, impossible installation, etc. The cable effect is obvious, the construction efficiency is improved, and the operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

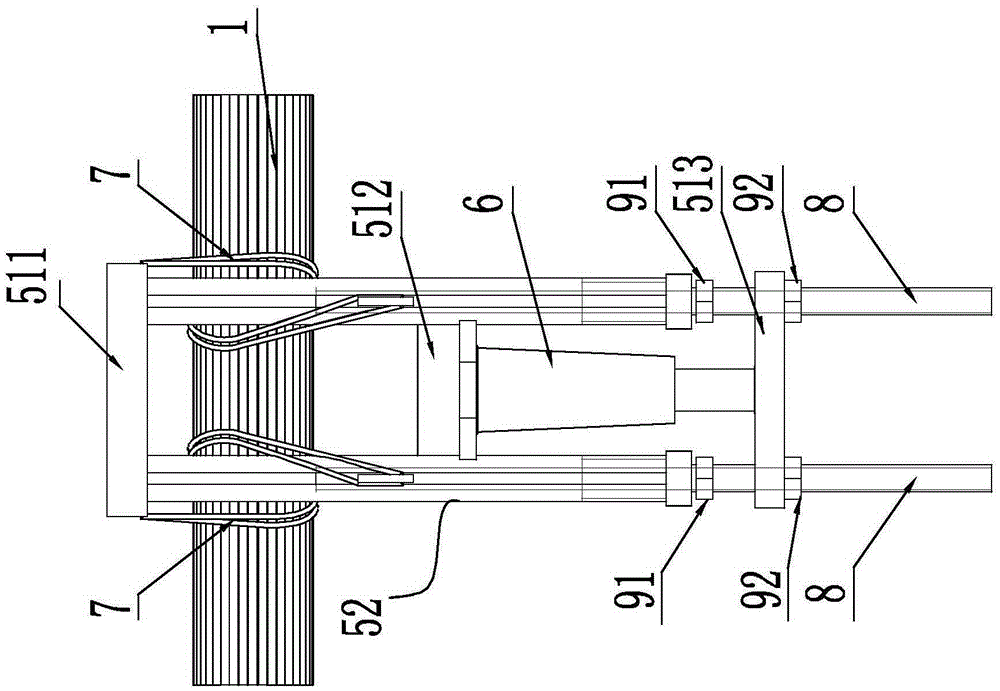

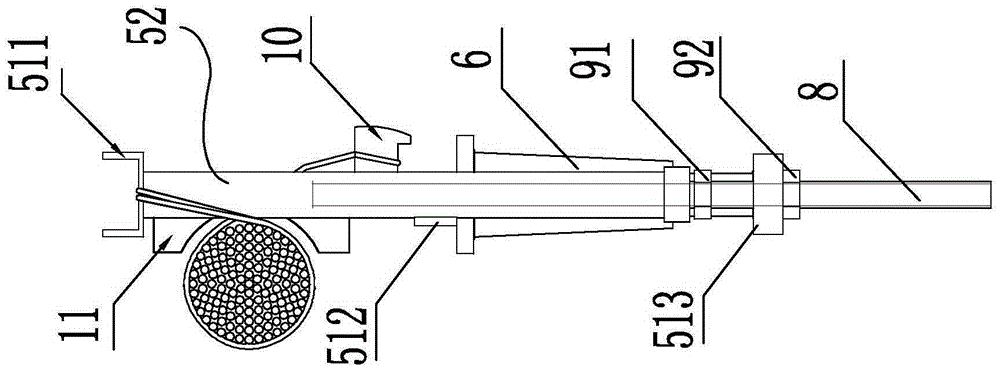

[0036] A cable tensioner for parallel steel strands, such as figure 2 , image 3 As shown, the tensioner includes: a frame 5, a jack 6, an adjusting jack 8 and a matching flexible band 7;

[0037] The frame 5 includes three beams of fixed cross-connection I 511, fixed cross-connection II 512 and movable cross-connection 513, two vertical beams with grooves 52, two special-shaped steel structures 11 and two reaction hooks 10; fixed cross-connection I 511 Installed on the top of the two vertical beams with grooves, the fixed cross-link II 512 is installed between the two vertical beams with grooves 52 and fixedly connected with them to make it a whole, and the two adjusting push rods 8 pass through the movable cross-links 513 and installed respectively In the grooves of the two vertical beams with grooves 52 of the frame and can move freely in the grooves of the vertical beams with grooves 52, the adjusting push rod 8 has external threads and is fixed on a certain position on ...

Embodiment 2

[0042] A method for tight cable construction, which is a method for using a parallel steel strand cable tensioner described in Embodiment 1 for tight cable construction, and its construction steps are:

[0043] A. Initial tension:

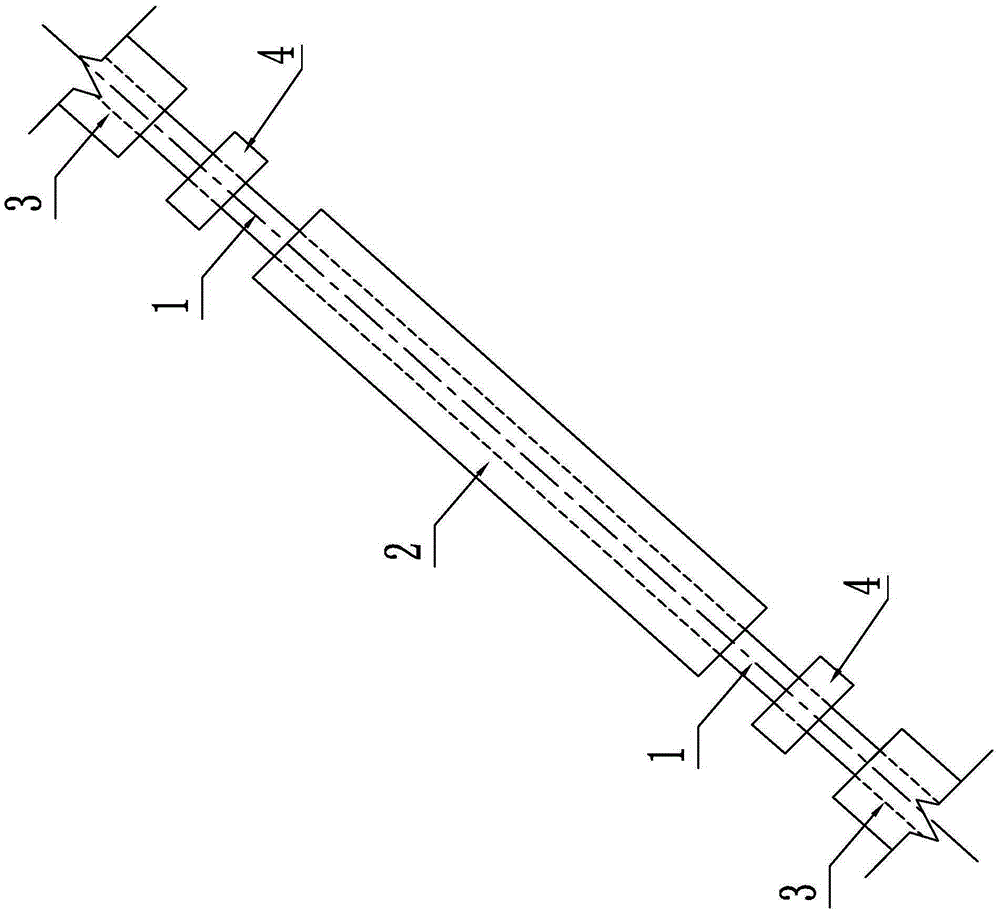

[0044] Install the stay cable outer sheath round tube 2 and the stay cable pre-buried tube 3, and install the steel strand unit 1 in the sheath tube. When the space in the round tube is not enough to install the subsequent steel strand unit, install the cable tensioner 4 Initial tensioning of installed strand units;

[0045] B, shelve the tensioner 4 on the outer surface of the steel strand body unit 1 (see Figure 1-Figure 3 ):

[0046] Among them, the inner arc surface of the special-shaped steel structure 11 is matched with the outer circular surface of the steel strand body unit 1, and one end of the flexible band 7 is connected to the horizontal connecting plate of the frame, and the other end is wound on the installed steel strand body unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com