Hydraulic machine rack installation method

An installation method and technology of hydraulic presses, which are applied in the directions of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to complete the installation of large-volume and heavy-weight racks, and the inability of crane hoisting capacity to meet rack installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention is described in detail below with reference to accompanying drawing and embodiment:

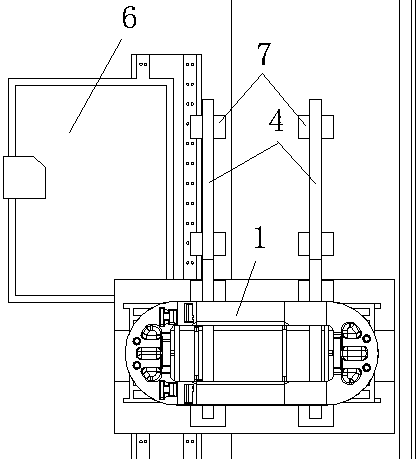

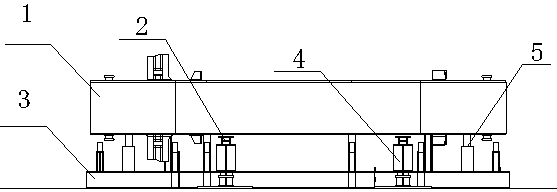

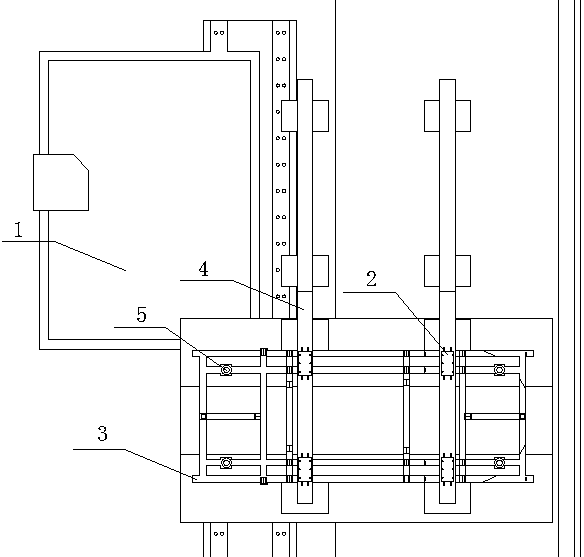

[0077] attached Figure 1-22 It can be seen that a method for installing a hydraulic press frame includes the following steps:

[0078] Step 1. Lay the translation track. After the frame is wound, use a jack to lift the frame by 200mm at the reserved position of the winding base of frame 1, and then install the transport trolley 2; the frame translation track is 500×700 welded H-shaped steel, the machine The frame transport adopts the transport trolley;

[0079] Step 2. The rack is lowered from the paired frame to the translation track. The height of the translation track and the transport trolley is 1360mm. After the rack is lifted by a jack, the height of the bottom surface is 1400mm. Therefore, the rack needs to be lowered by 40mm to ensure that the rack falls back to the transport trolley. ;

[0080] Step 3, the rack is moved in translation, and the rack is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com