Combined type movable hanger

A mobile hanger and combined technology, applied in the direction of load hanging components, hoisting equipment braking devices, trolley cranes, etc., can solve the problems of difficult setting of lifting points, improve work efficiency and maintenance safety, Reasonable structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

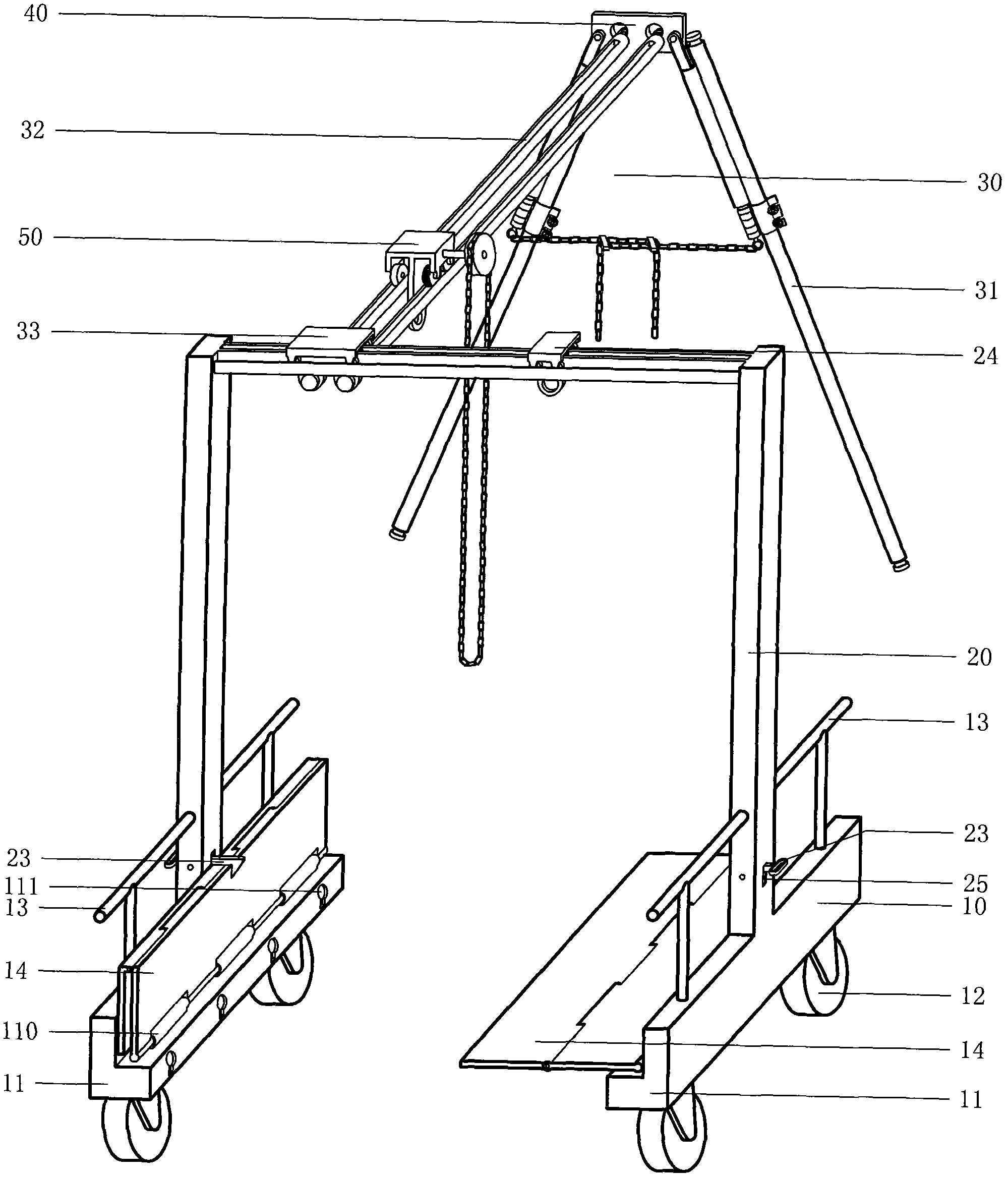

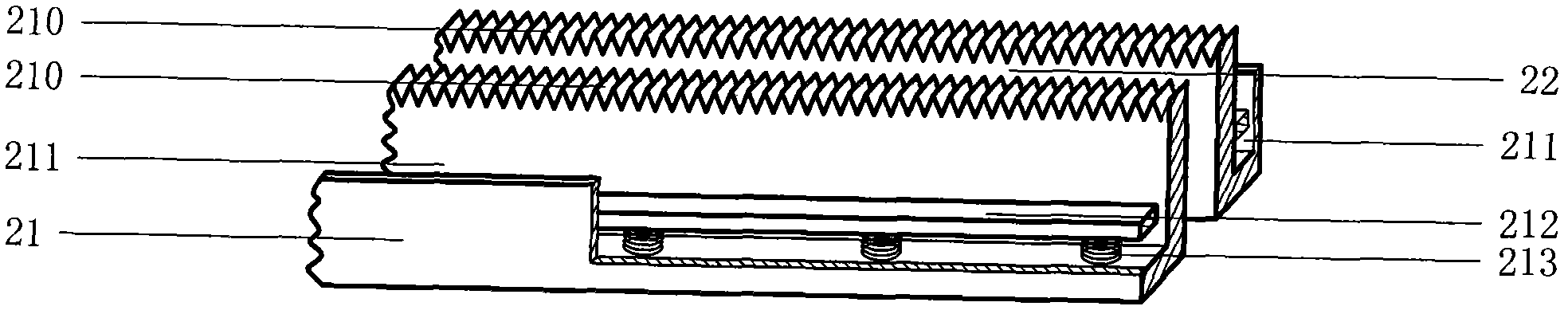

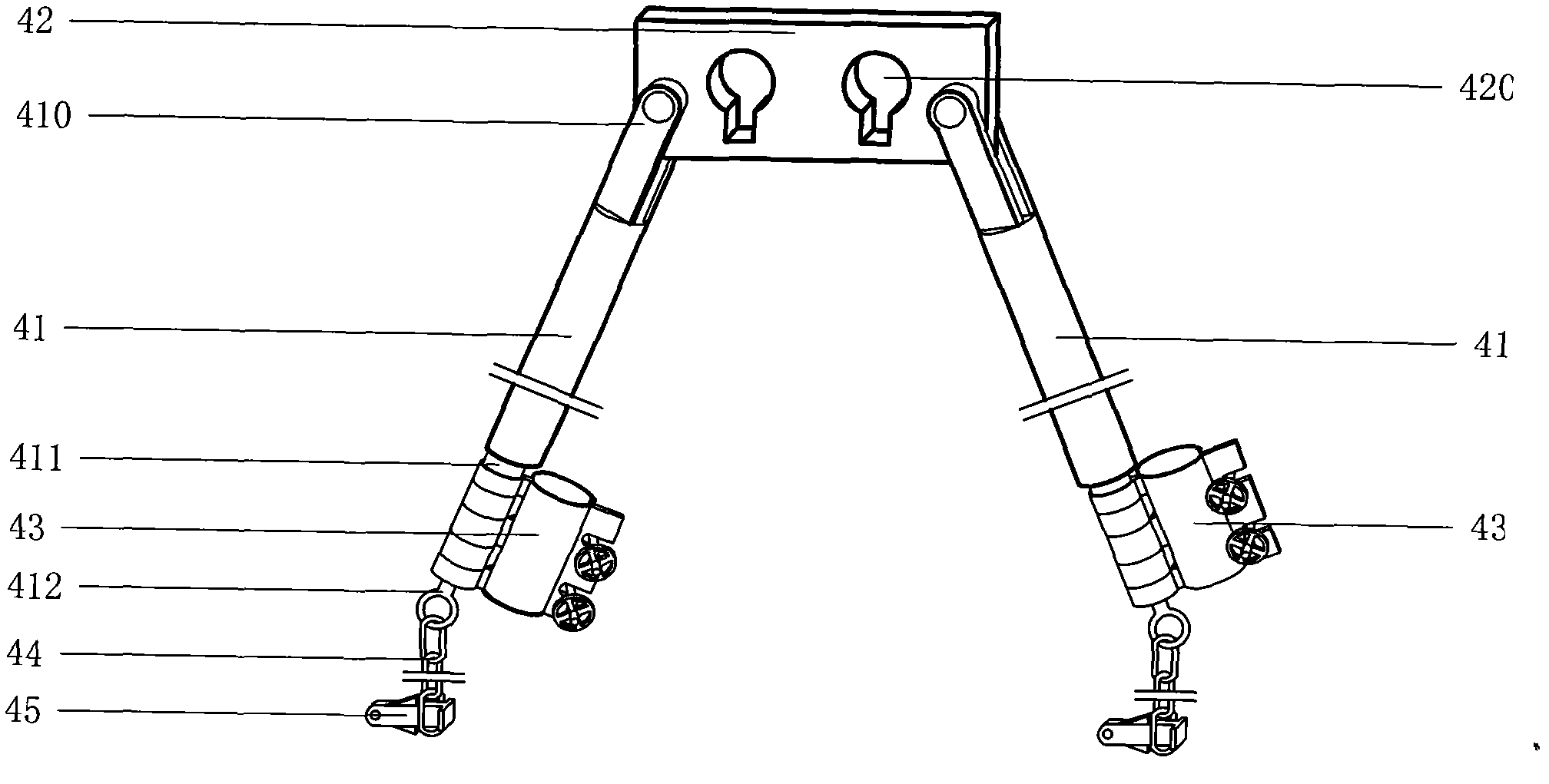

[0028] see figure 1 and combine figure 2 , 3, 4, 5, 6, 7, 8, 9, 10, the combined mobile hanger of this embodiment includes a mobile frame 10, a door type hanger 20 and a fork type combined frame 30, and the mobile frame 10 includes a corner Type vehicle beam 11, carrying roller 12, push-pull handle 13 and carrying compartment plate 14, described angle type vehicle beam 11 is provided with compartment panel hinge 110 and bar interface 111; 10, its top beam includes a trough-shaped hanging beam 21 and a rail hanging slide 22, and the trough-shaped hanging beam 21 is provided with a limited-slip tooth track 210, a rail hanging wheel groove 211, a lifting groove plate 212 and a top plate spring 213. The door-type hanger 20 is provided with a box plate buckle 23 and a door frame rail hanger 24; the fork-type combined frame 30 is combined with the mobile frame 10 and the door-type hanger 20 to form a hand-push truck or a lifting hanger , its structure includes integrated base fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com