Connecting method and structure of crane beam for self adaptable column sedimentation

A technology for connecting structures and crane girders, applied in the direction of supporting structures, load hanging components, transportation and packaging, etc., can solve the problems of large difference in compressibility of soil layers, difficulty in adjusting foundation settlement to the same level, etc., and achieve good vertical deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

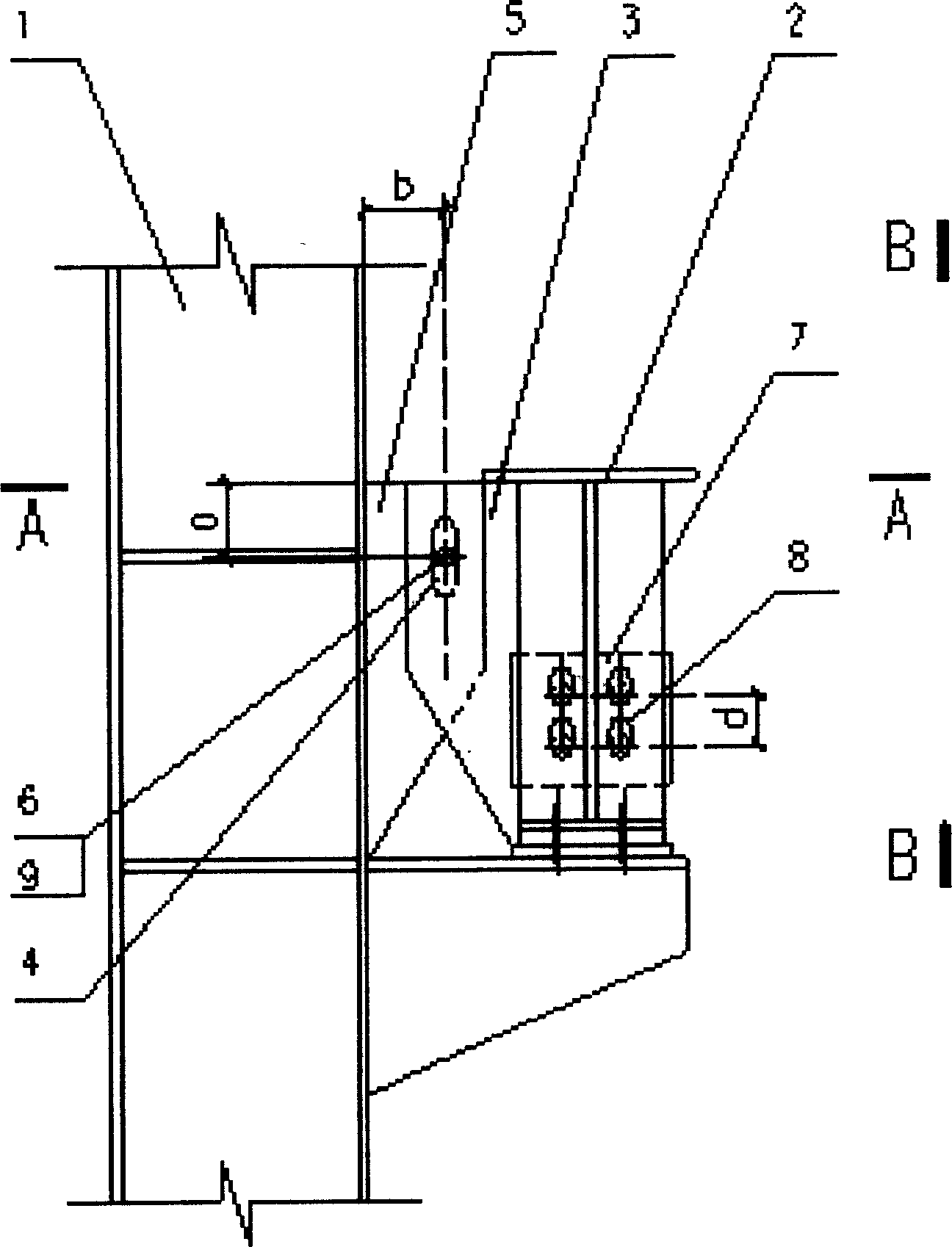

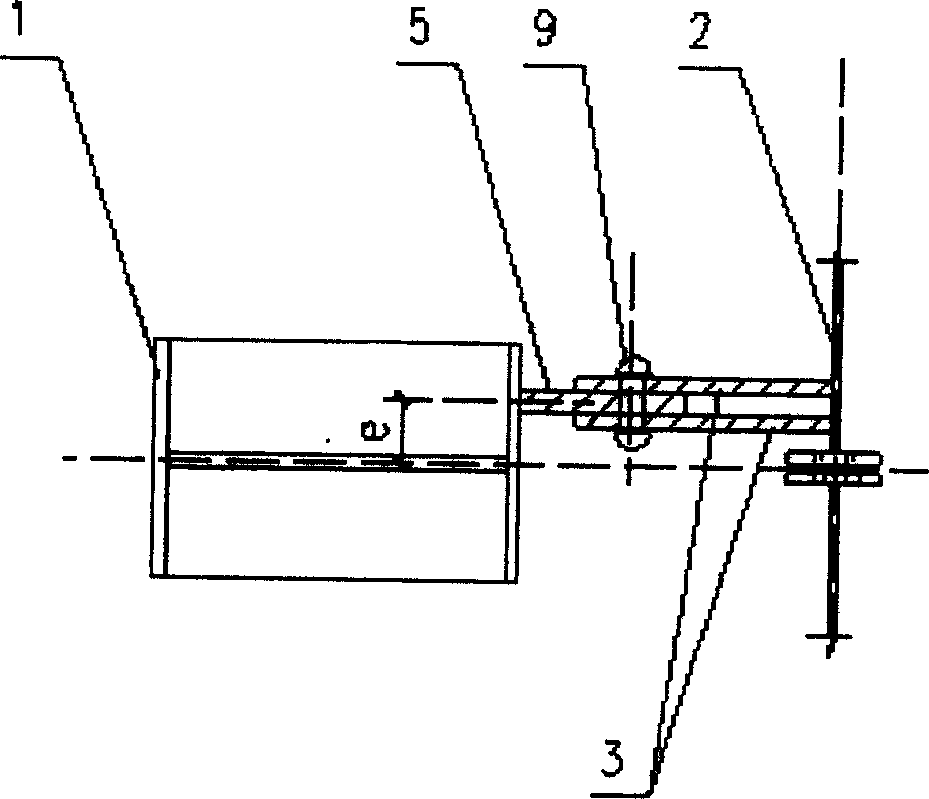

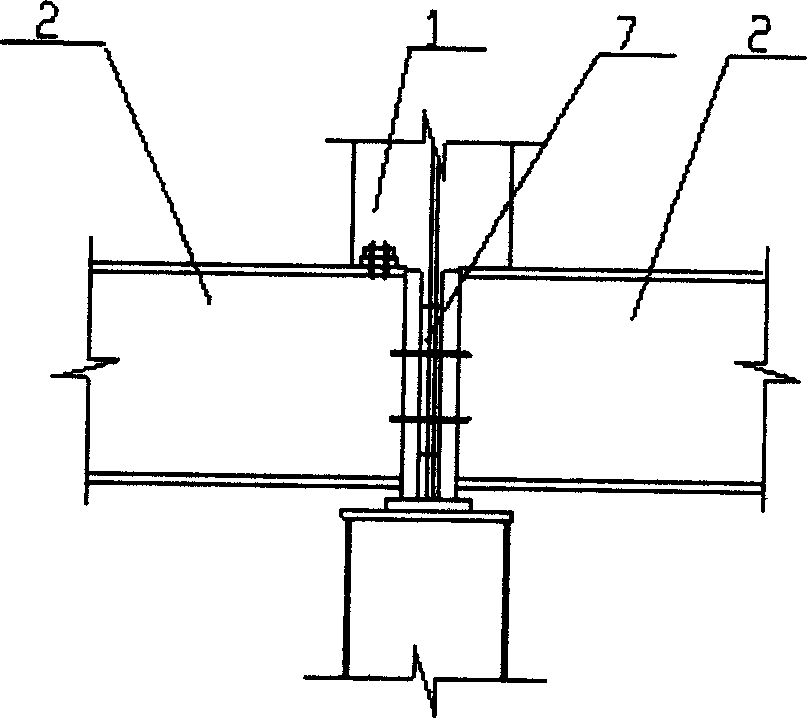

[0011] Embodiment of the present invention: open a vertical oval hole (4) on two steel plates (3), respectively weld the two steel plates (3) on the steel crane beam (2), and open the two steel plates (3) on the splint (5) A circular hole (6), the clamping plate (5) is welded on the factory building column (1) and the clamping plate (5) is placed in the middle of two steel plates (3), so that the circular hole (6) and the vertical oval hole ( 4) overlap, then insert a pin (9) in the circular hole (6) to connect them together; open a vertical ellipse on the connecting plate (7) of the crane beam (2) connecting the adjacent crane beam hole (8), and the bolts are inserted into the vertical oval hole (8). When connecting, the vertical distance a between the center of the pin (9) and the top of the steel crane girder (2) is 100 mm to 300 mm, and the distance b from the side of the factory column (1) is 60 mm to 300 mm. The center of the pin (9) The deviation distance e from the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com