Hydraulic hoisting, slipping and emplacing method and equipment for large scale press components

A hydraulic lift and press technology, applied to cranes, traveling mechanisms, load suspension components, etc., can solve problems such as difficult installation and anchoring of hoists, guide sliders, and wind ropes, difficulty in recovery, and poor safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

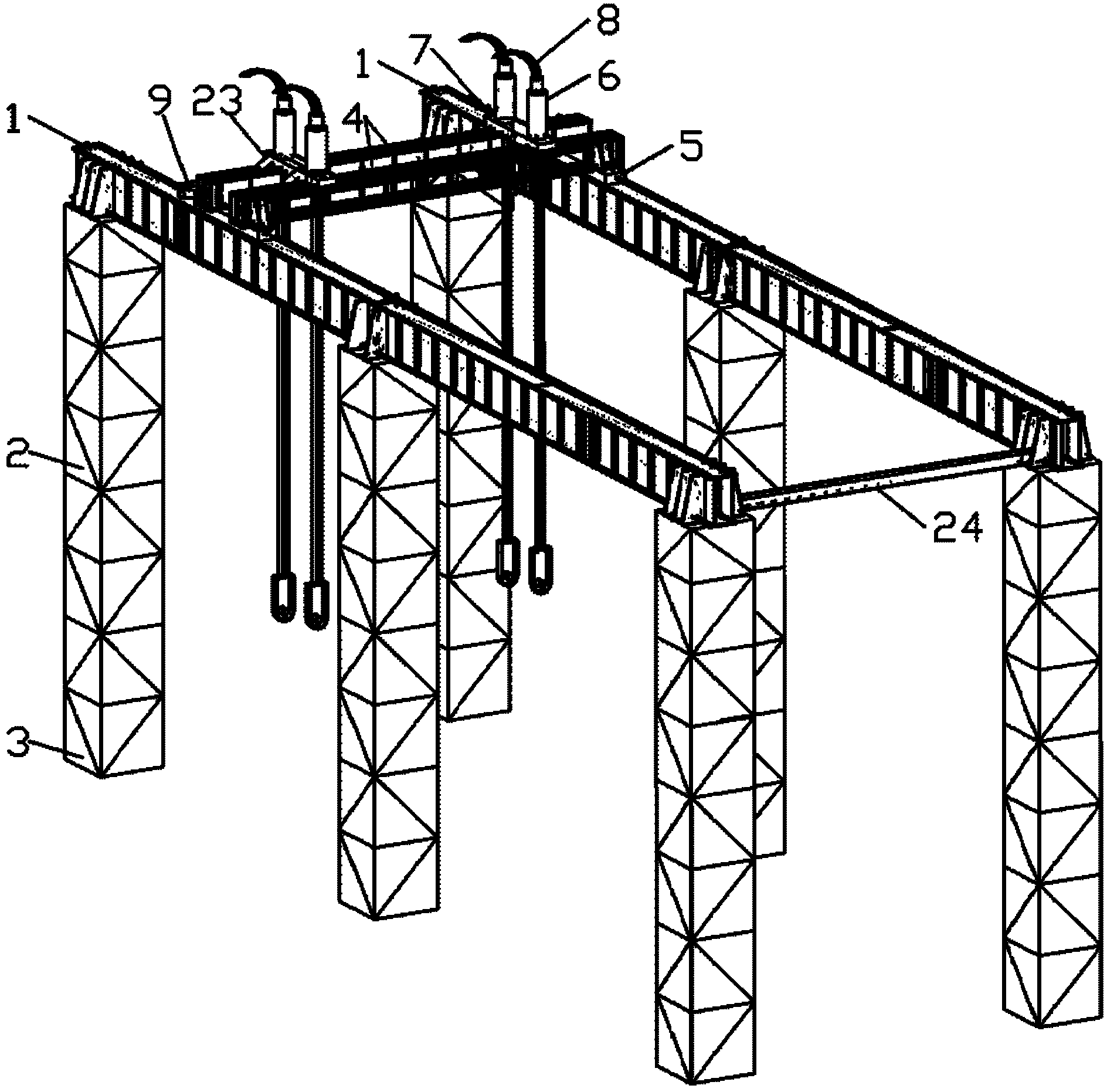

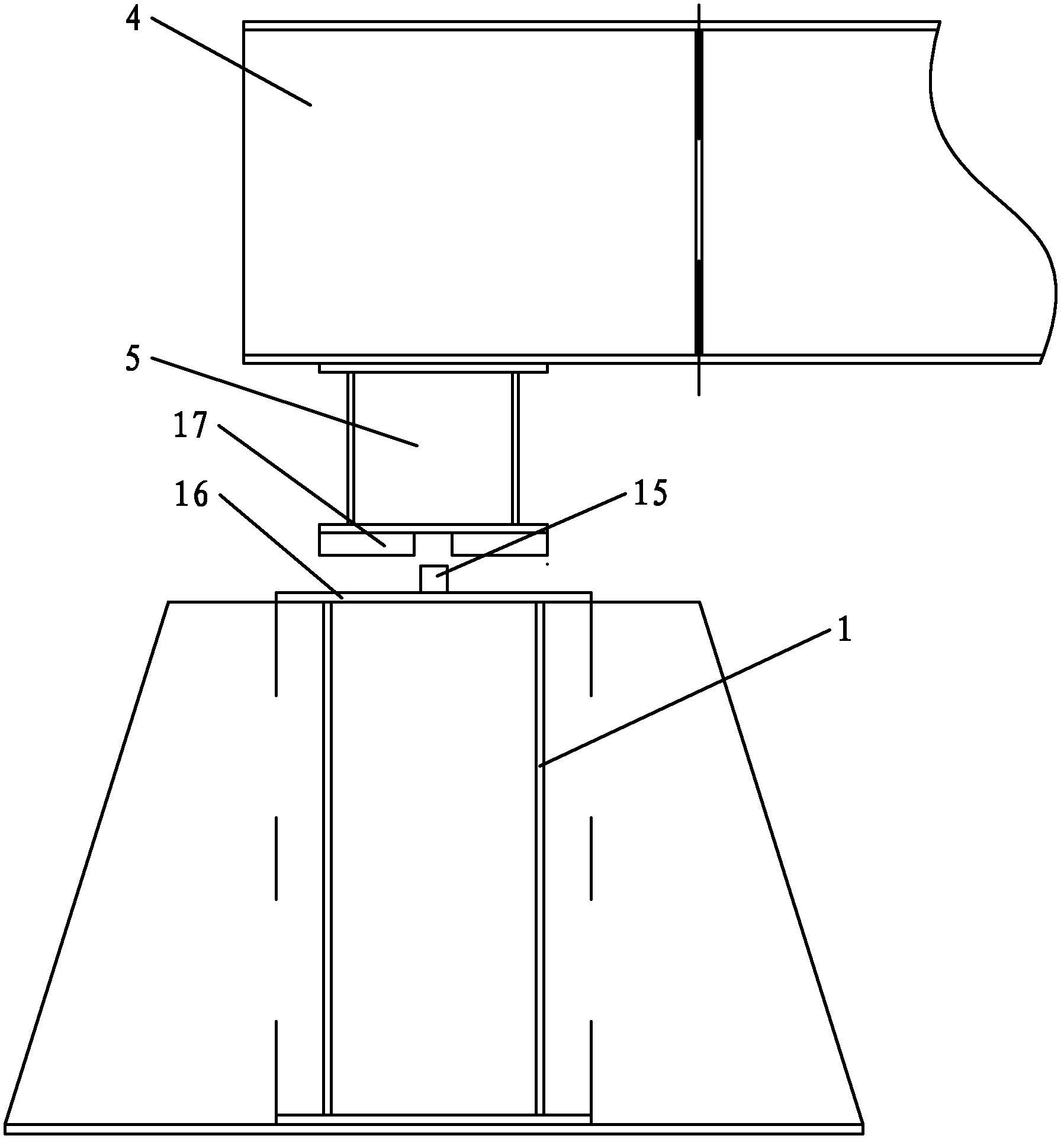

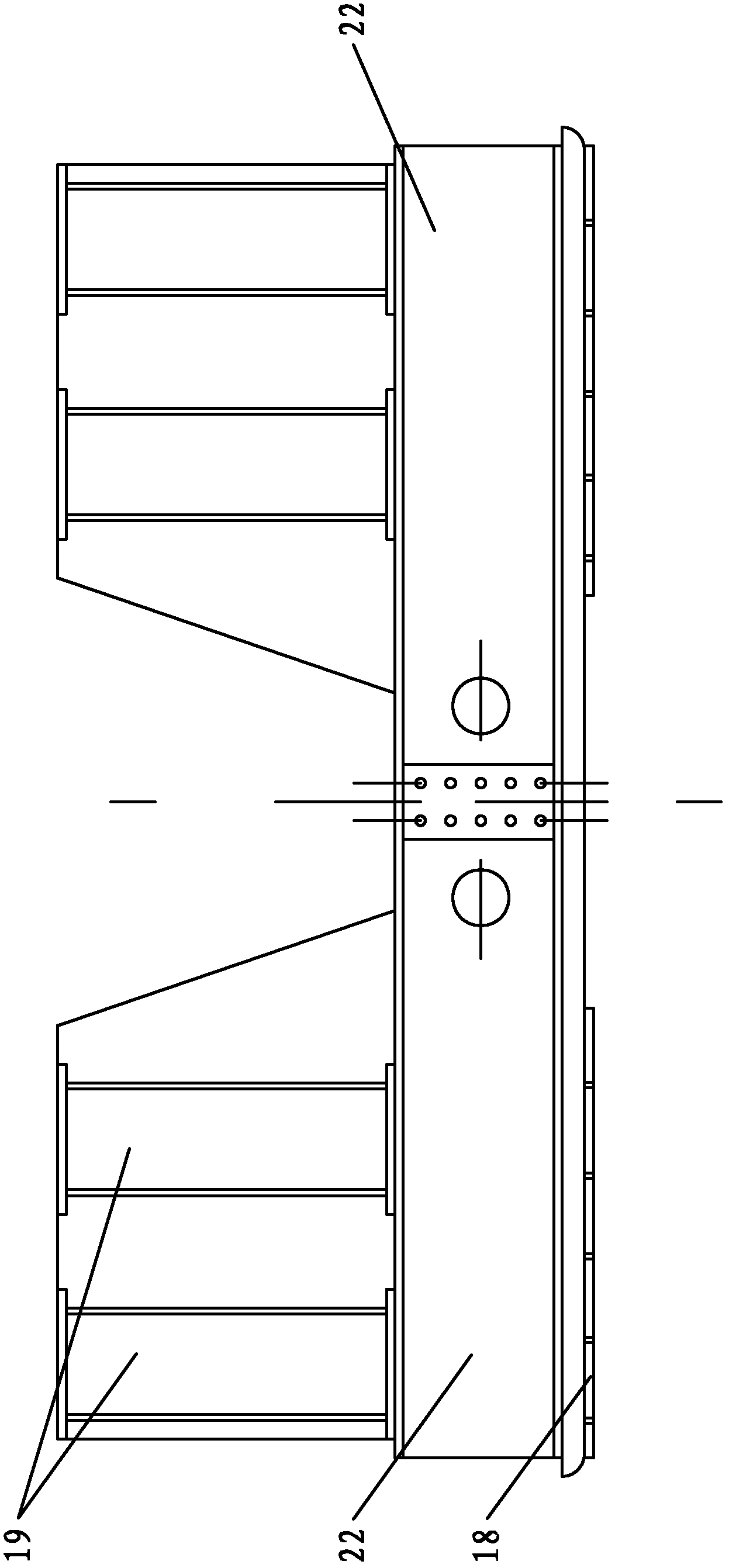

[0040] Such as figure 1 As shown, the hydraulically lifting and sliding positioning equipment for large press components of the present invention includes two main beams 1 arranged horizontally and parallel to each other, and a connecting small beam 24 is connected between the two ends of the two main beams 1 . The bottom of each main beam 1 is fixedly connected with three uprights 2, and the bottom of each upright 2 is connected with a foundation base 3 connected to the ground by bolts, and two parallel hoisting beams 4 are arranged above the two main beams 1 , the two ends of the two lifting beams 4 are installed on the upper end surface of the main beam 1 through the end beam 5, and two lifting cylinders 6 are arranged above each lifting beam 4, and each lifting cylinder 6 passes through the lifting cylinder base 7 at the bottom Installed on the upper end surface of the hoisting beam 4, each lifting cylinder 6 is provided with several steel strands 8, the lower end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com