Double-beam cantilever crane

A crane and cantilever technology, applied in the field of double-girder cantilever cranes, can solve the problems affecting the normal processing and production of workshops, inflexible use of cranes, and large floor space, and achieve the effects of simple structure, low cost, and reduced floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

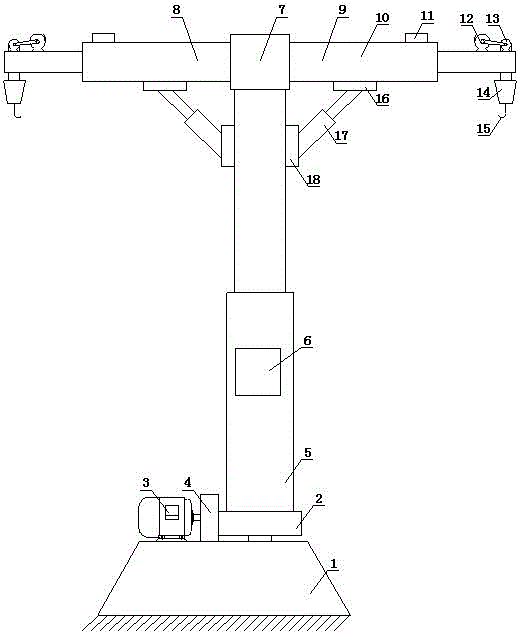

[0017] Such as figure 1 Shown, a kind of double girder cantilever crane, it comprises fixed base 1, described fixed base 1 is provided with motor A3 and gear 2, the output shaft of described motor A3 is connected the input shaft of reduction box 4, described The top of the gear 2 is provided with a telescopic column 5, the bottom of the telescopic column 5 is provided with a controller 6, the top of the telescopic column 5 is provided with a fixed block 7, and the left and right sides of the fixed block 7 are arranged symmetrically. There are main beam A8 and main beam B9, the main beam B9 includes a telescopic rod 10, the upper part of the telescopic rod 10 is provided with a levelness detector 11, and the end of the telescopic rod 10 is provided with a motor B12, so The motor B12 is connected with a lifting pulley 13, the lifting pulley 13 is connected with a pulley block 14, the bottom of the pulley block 14 is provided with a hook 15, and the bottom of the telescopic rod 1...

Embodiment 2

[0020] Such as figure 1 Shown, a kind of double girder cantilever crane, it comprises fixed base 1, described fixed base 1 is provided with motor A3 and gear 2, the output shaft of described motor A3 is connected the input shaft of reduction box 4, described The top of the gear 2 is provided with a telescopic column 5, the bottom of the telescopic column 5 is provided with a controller 6, the top of the telescopic column 5 is provided with a fixed block 7, and the left and right sides of the fixed block 7 are arranged symmetrically. There are main beam A8 and main beam B9, the main beam B9 includes a telescopic rod 10, the upper part of the telescopic rod 10 is provided with a levelness detector 11, and the end of the telescopic rod 10 is provided with a motor B12, so The motor B12 is connected with a lifting pulley 13, the lifting pulley 13 is connected with a pulley block 14, the bottom of the pulley block 14 is provided with a hook 15, and the bottom of the telescopic rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com