Main girder of single-girder crane

A crane and single girder technology, applied in the direction of load hanging components, transportation and packaging, supporting structure, etc., can solve the problem of poor welding conditions of the internal ribs of the box-shaped main girder, large width of the box-shaped steel plate of the main girder, and steel plate forming process Trouble and other problems, to save the length of the weld, reduce the weight of the main beam, improve the effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

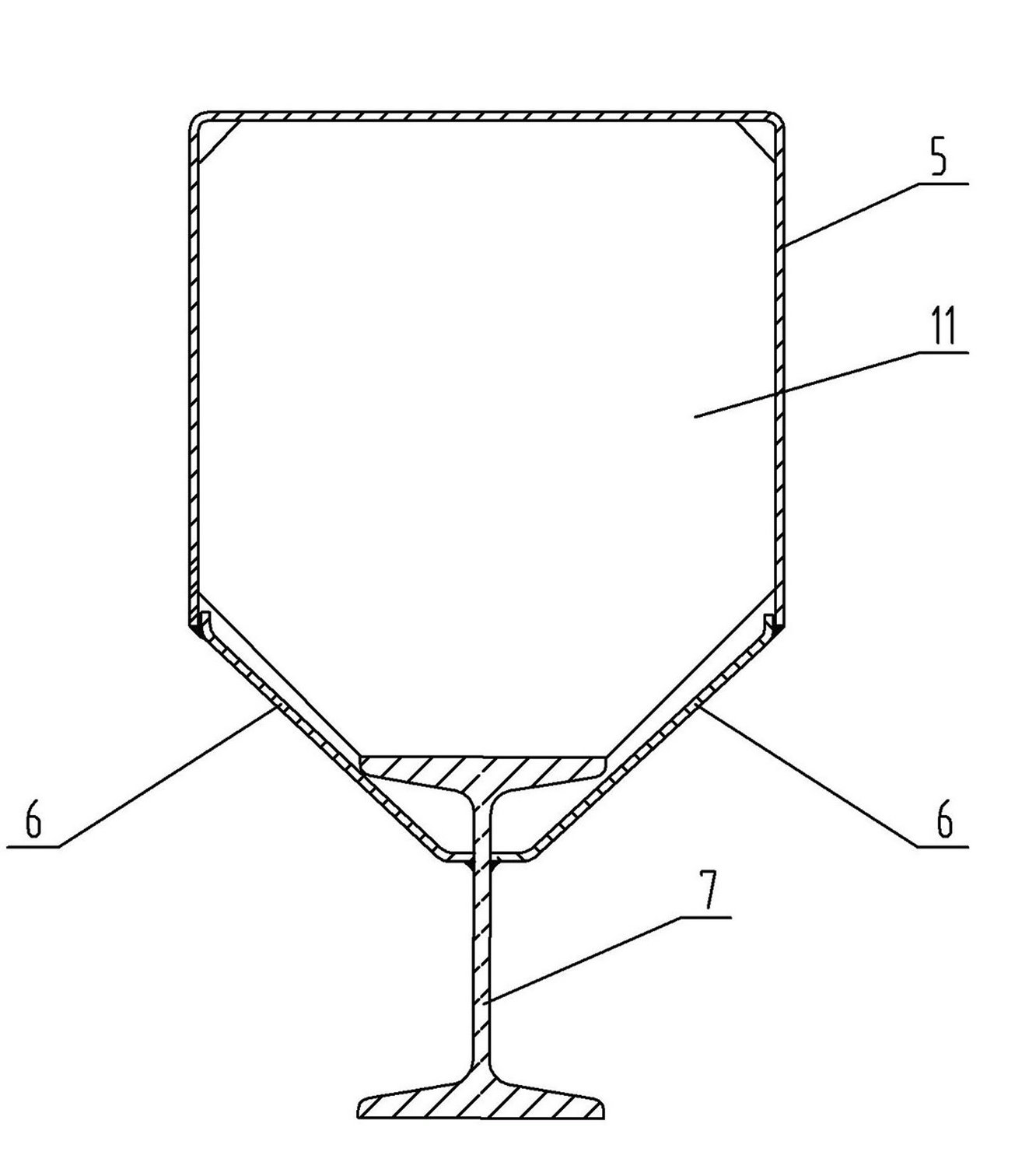

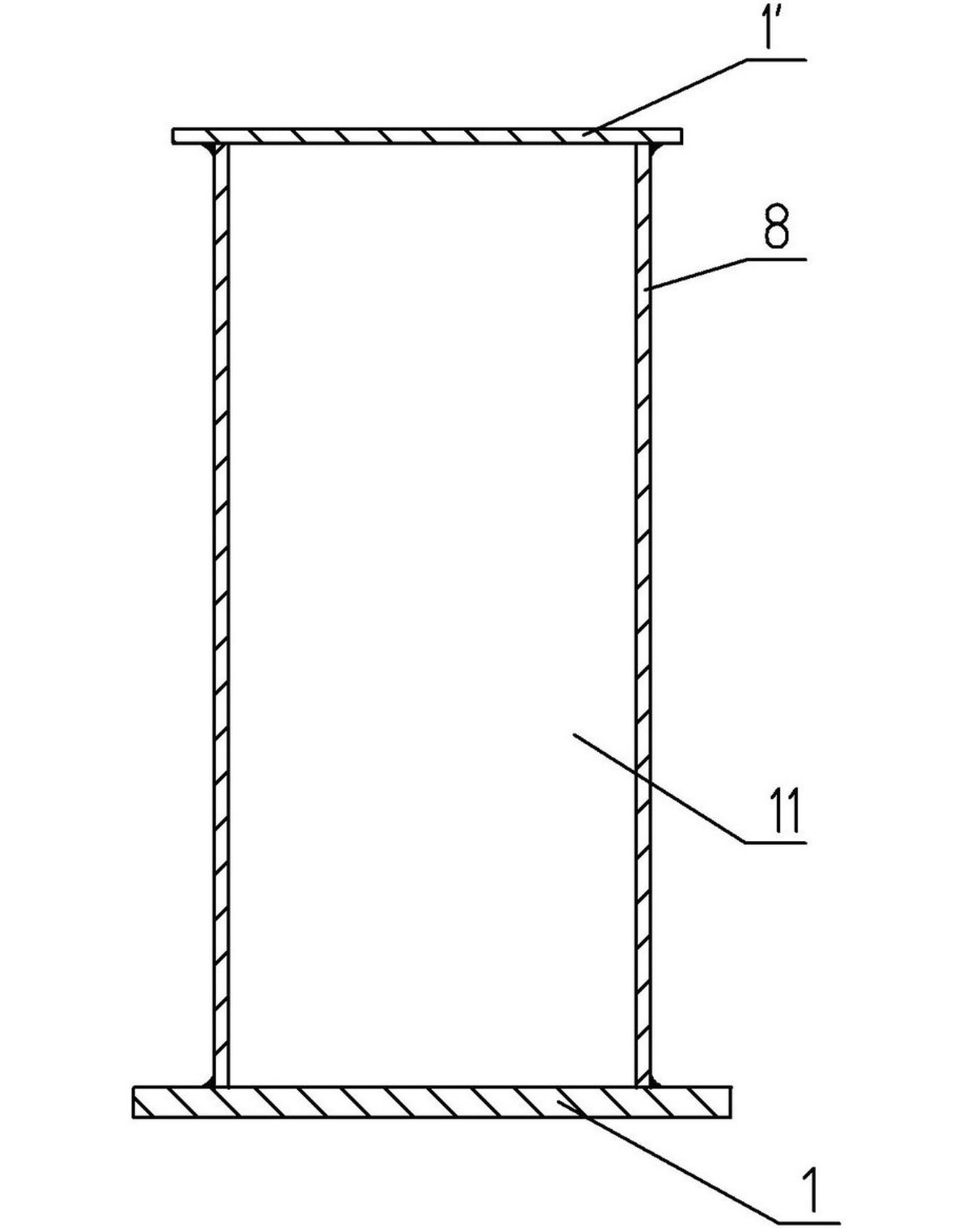

[0043] see Figure 5 , Figure 6 , in the figure, the girder of the single-girder crane of the present invention includes an upper load-bearing plate 16, a lower load-bearing plate 1″, and two symmetrical special-shaped sides that weld the upper load-bearing plate 16 and the lower load-bearing plate 1″ together. Plates 17, 17', reinforcement plates 11 are fixed at intervals along the transverse direction in the inner cavity of the beam main body, the cross section of the main beam is an approximate composite section, the upper part is a lower opening rectangle 9', and the middle is an upper and lower opening inverted, etc. Waist trapezoidal 9 ", the bottom is an upper opening rectangle 10 ', and the long sides and wide sides of the upper lower opening rectangle 9 ' are greater than the long sides and wide sides of the lower upper opening rectangle 10 ', and the width of the upper bearing plate 16 is greater than two The maximum width between the side plates 17, 17', the width...

Embodiment 2

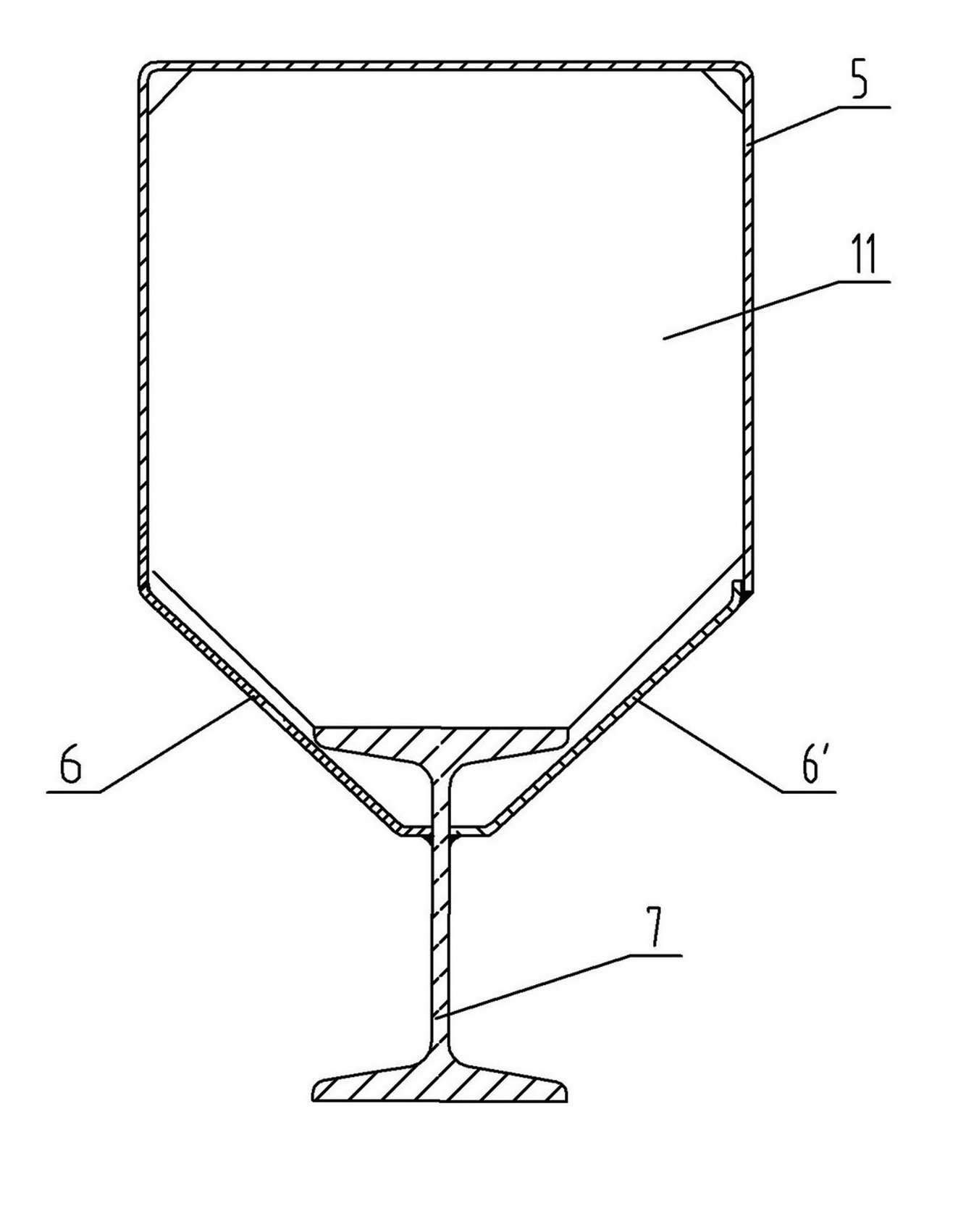

[0049] see Figure 7 to Figure 9 , in the figure, the meanings of the same numbers in this embodiment and the first embodiment are the same and will not be repeated. The difference is that there is also a strip-shaped transition steel plate 13 between the upper load-bearing plate 16 and the reinforcing plate 11 in this embodiment. , the transitional steel plate 13 is welded on the upper end surface of the reinforcement plate 11, and the corresponding position of the transitional steel plate 13 and the upper load-bearing plate 16 is horizontally provided with a slender rectangular through-hole 14, through which the transitional steel plate 13 and the upper load-bearing plate 16 are connected from the outside. welded together; the length of the transition steel plate 13 is slightly smaller than the width of the reinforcing plate 11, the length of the through hole 14 is slightly shorter than the length of the transition steel plate 13, and the width of the through hole 14 is small...

Embodiment 3

[0053] see Figure 10 The meanings of the same numbered parts in this embodiment and the second embodiment are the same and will not be repeated. The difference is that the reinforcing plate 11 in this embodiment is provided with a through hole 15 with a flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com