Underground pipeline safety monitoring device based on stress induction technology

An underground pipeline and safety monitoring technology, which is applied in the fields of electronics and optics, can solve problems such as hidden safety hazards, pipeline deformation, pipeline twisting force, etc., and achieve the effects of comprehensive monitoring and monitoring process, avoiding catastrophic accidents, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

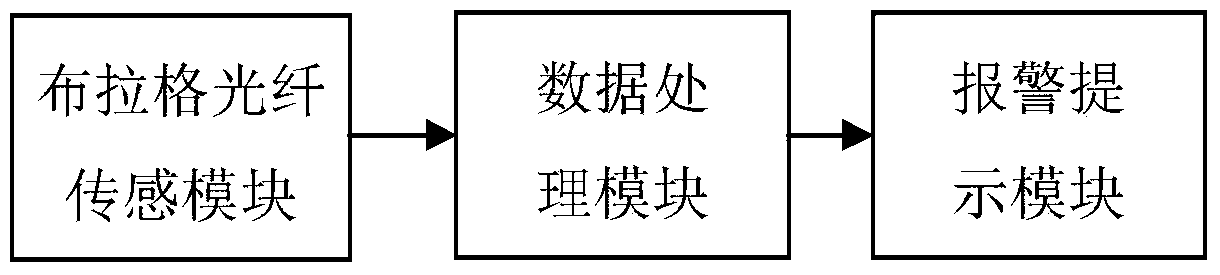

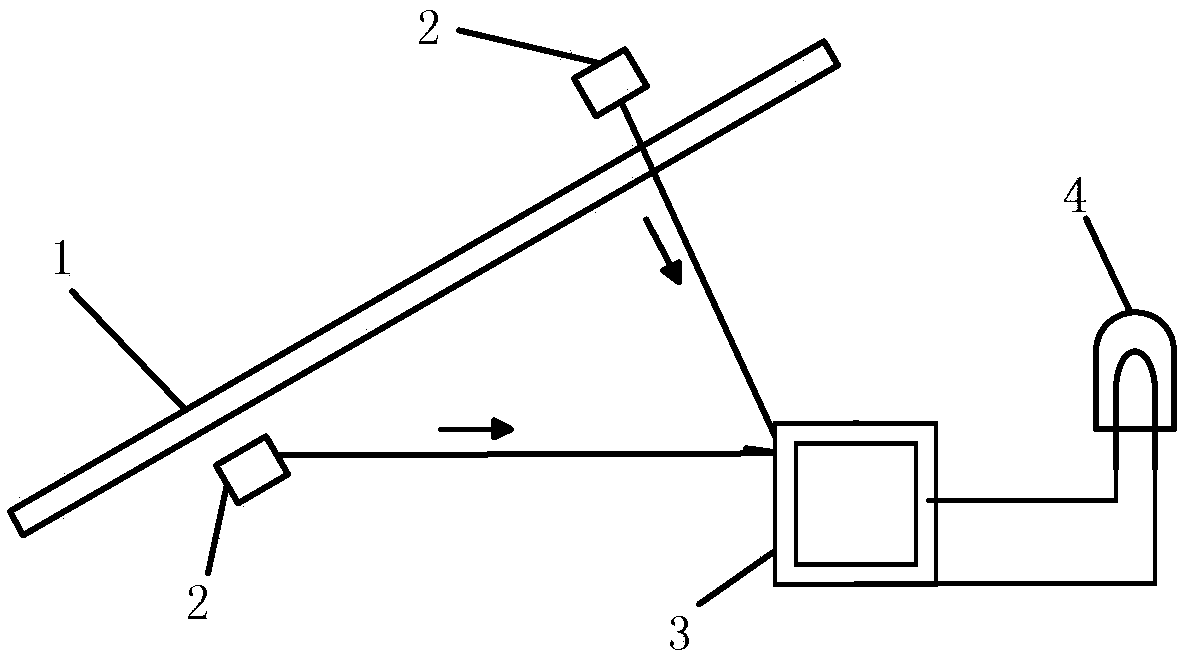

[0010] Such as figure 1 As shown, the Bragg fiber optic sensing module is composed of multiple groups of Bragg fiber grating sensors, which are distributed throughout the entire underground pipeline system. Through remote stress sensing, the force status of each pipeline can be monitored, so that the force status can be transmitted to the data processor in time . The data processing module sets corresponding thresholds according to the different environments in which the pipeline is located, and analyzes the stress conditions delivered by the optical fiber sensor. If the stress exceeds or approaches the threshold, it sends a signal to the alarm notification module to give an alarm in time.

[0011] The Bragg optical fiber sensor module refers to a new type of sensor in which gratings are periodically distributed in the spatial phase formed inside the core of the sensor to act as mirrors and filters, so as to select The wavelength of the Bragg condition is reflected to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com