Combined lining structure based on polyhedral duct pieces for tunnel

A polyhedral tube and hexahedral tube technology, which is applied to tunnel lining, tunnel, wellbore lining, etc., can solve the problems of single form, interruption of the force transmission path to the annular segment, and segment cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

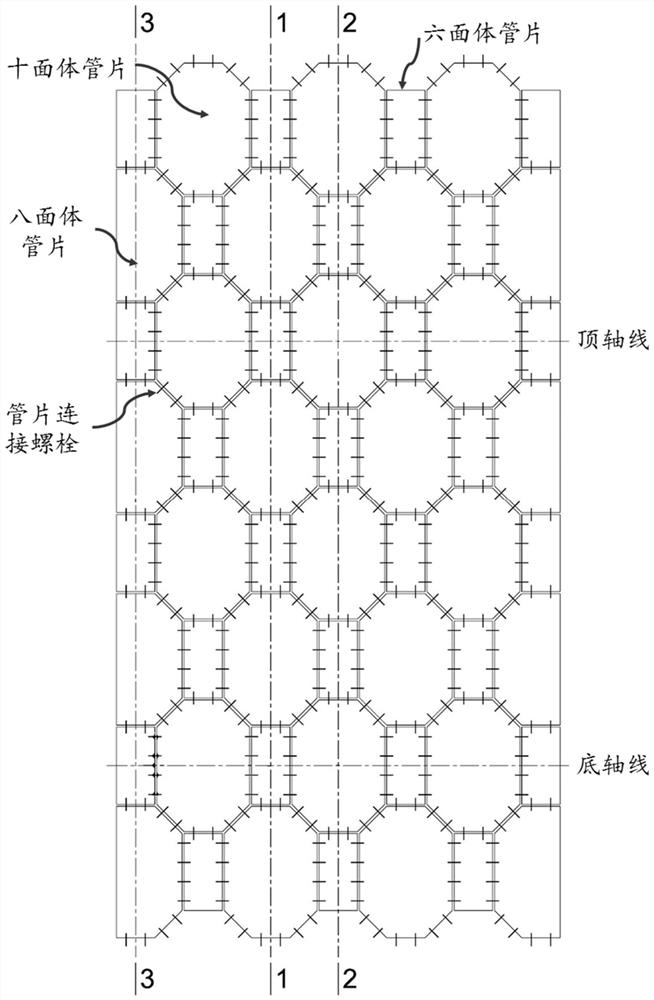

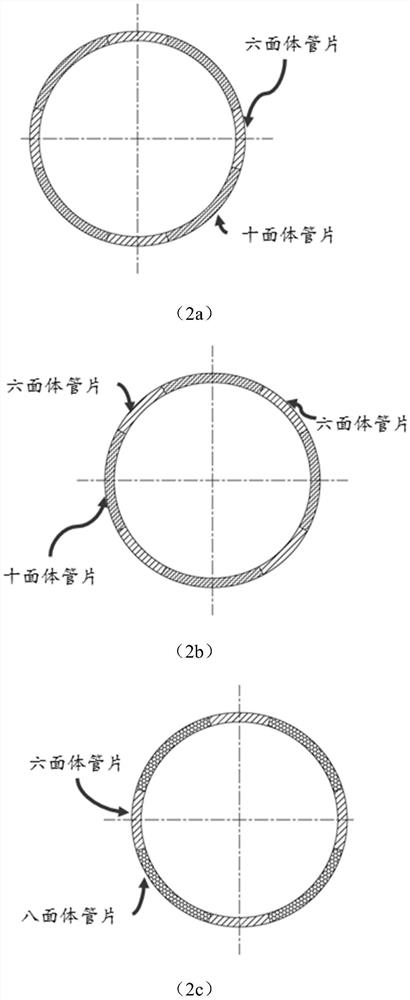

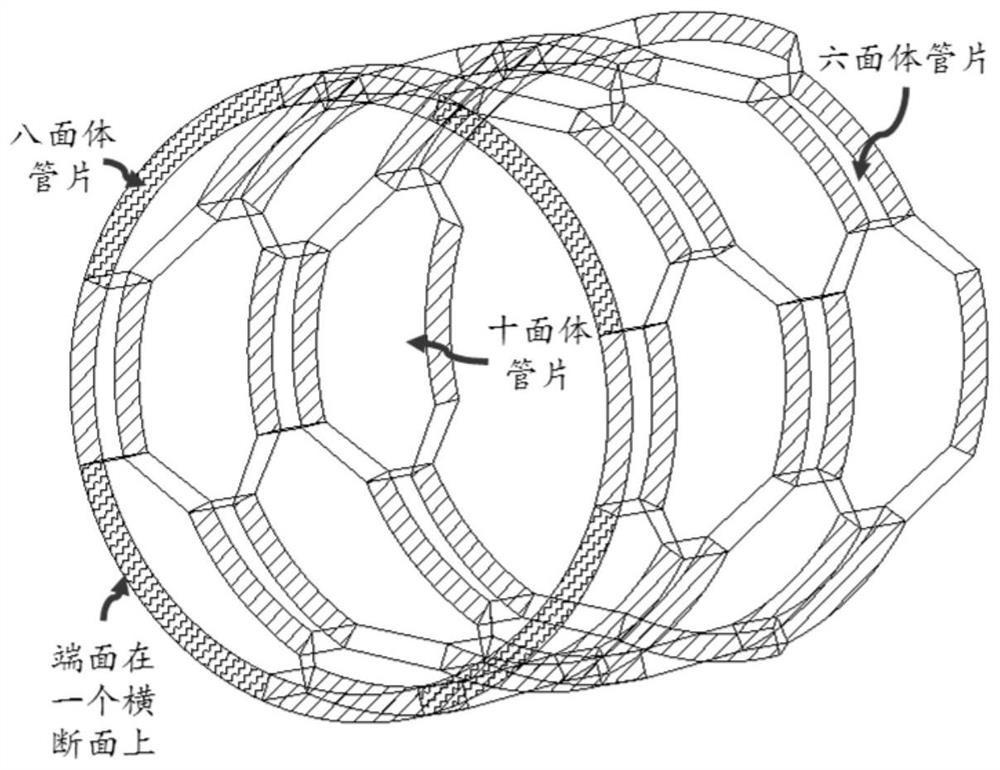

[0025] like Figure 1-5 As shown, the present invention provides a composite lining structure for tunnels based on polyhedral segments. The composite lining structure is assembled into a cylindrical shape by combining multiple hexahedral segments, multiple octahedral segments and multiple decahedral segments. Except for the ring composed of hexahedron and octahedron at the end of the tunnel, where the sides of the segments are on one cross-section, all other standard rings composed of decahedron and hexahedron, the end face ring composed of octahedron and hexahedron, its longitudinal seams and rings The joints are not on the same plane. Due to the interaction and load transfer between the segments, there will be no obvious weak surface between the tunnel segments, which is beneficial to the improvement of the tunnel bearing capacity and the waterproofing of the tunnel structure.

[0026] The segment assembly of the present invention does not have the intersecting of the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com