Glass cracking automatic explosion-proof device

An explosion-proof device and glass technology, which is applied in the direction of automatic disconnection emergency protection device, circuit device, emergency protection circuit device, etc., can solve the problems of fragility hidden dangers, explosion-proof and explosion-proof structure damage, electrical contact sparks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

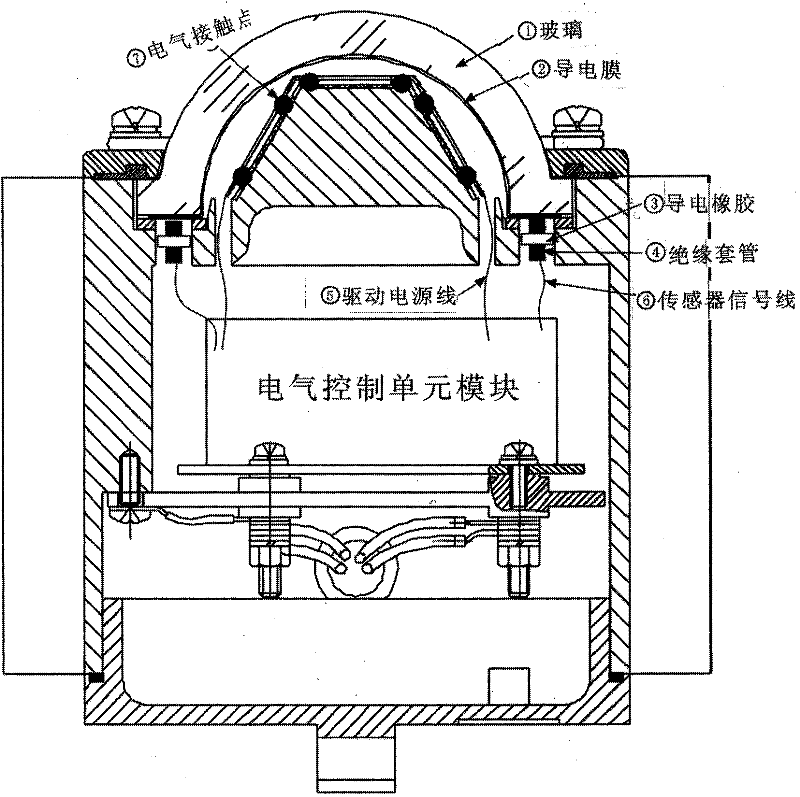

[0022] Example 1. Automatic explosion-proof device for the rupture of the glass lampshade of mine explosion-proof LED roadway lights

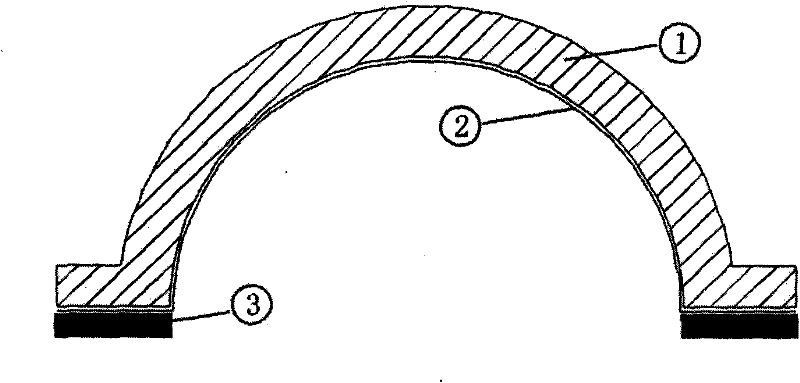

[0023] Figure 2-1 , Figure 2-2 , Figure 2-3 The different positions of the conductive film 2 on the glass lampshade are shown respectively, Figure 2-1 The conductive film 2 is located on the inner surface of the glass lampshade; the metal foil conductive film 2 is attached to the lampshade glass, and the resistance value of the conductive film is 0.001-1MΩ; Figure 2-2 The conductive film is located on the outer surface of the glass lampshade; Figure 2-3 The conductive film is embedded inside the glass.

[0024] image 3 It is a bottom view of the glass cover, and the conductive film 2 is arranged on the glass surface of the lampshade in a cross shape.

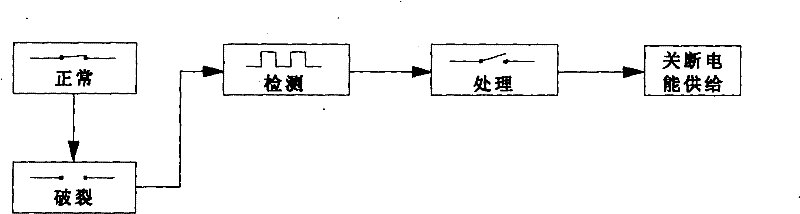

[0025] Image 6 Shown is the overall structure of the sensor assembly: when the LED roadway lamp is working normally, the conductive film 2 on the glass lampshade is in a low-resist...

Embodiment 2

[0026] Example 2 The automatic explosion-proof device for the glass breakage of the observation window of the electrical control cabinet

[0027] Figure 4 The flat glass and its conductive film are shown. The flat glass is more likely to be broken by external impact, and the conductive film is attached to the lampshade glass. The resistance value of the conductive film is 0.001Ω~1MΩ.

[0028] like Figure 5 Shown: The glass of the observation window of the electrical control cabinet is flat glass, and the principle of automatic notification of glass breakage of the observation window of the electrical control cabinet is similar to that of underground lighting fixtures used in coal mines. The difference is that the flat glass of the observation window of the electrical control cabinet is more easily broken, its internal space is larger, and the interior is filled with more flammable and explosive gases, which is more harmful.

[0029] Once the glass breaks due to external im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com