Preparing device and method of directional carbon nano tube reinforced metal matrix composite material

A carbon nanotube and composite material technology, which is applied in the field of preparing oriented carbon nanotube reinforced metal matrix composite materials and the field of oriented carbon nanotube reinforced metal matrix composite material preparation devices, and can solve the problem of difficulty in preparing oriented carbon nanotube reinforced metal matrix composite materials. and other problems, to achieve the effect of low cost and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

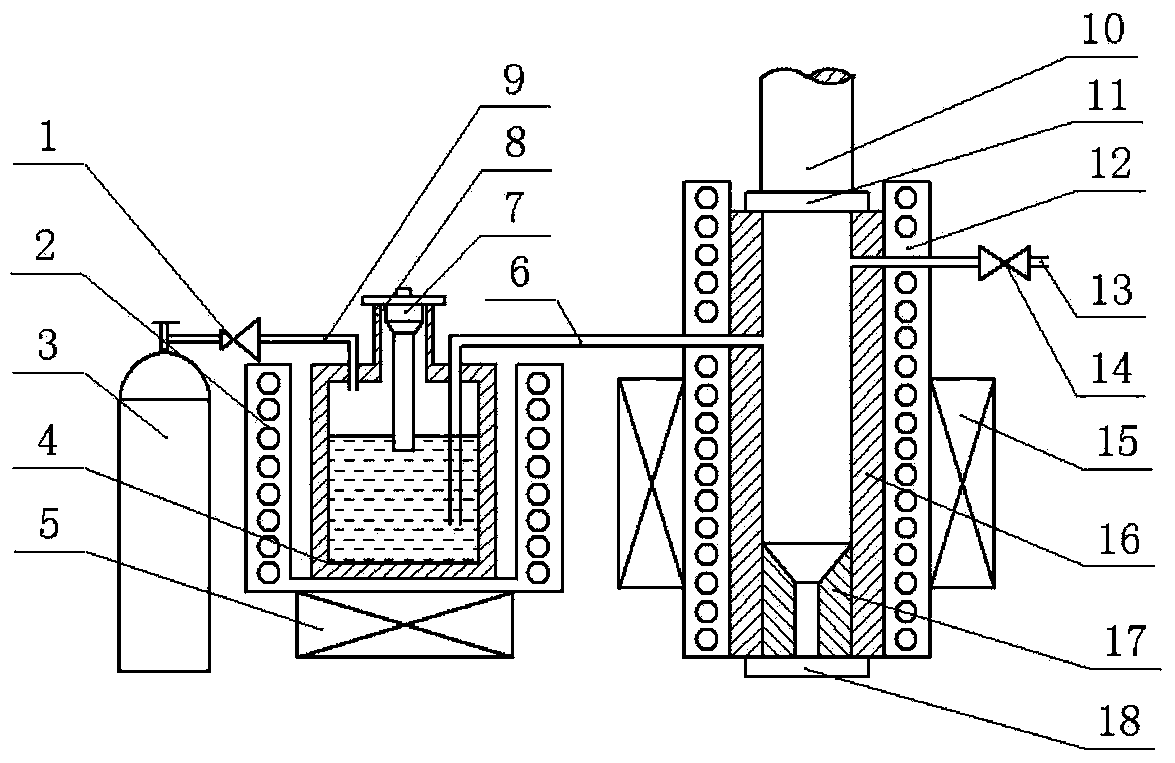

[0022] Method embodiment 1: a method for preparing oriented carbon nanotube reinforced magnesium-based composite material, comprising the following steps:

[0023] Step 1: Wrap the AZ91D magnesium alloy and multi-wall carbon nanotubes with aluminum foil and put them into the crucible 4 according to the volume fraction of 100:1, lower the punch 10 to press the pad 11, open the pressure reducing valve 1 and valve 14, and pass it into the pressure tank 3. The protective gas is introduced from the air pipe 9, flows through the infusion pipe 6, and finally is discharged from the exhaust pipe 13;

[0024] Step 2: Open the resistance furnace 2, melt all the AZ91D magnesium alloy in the crucible 4, open the resistance furnace 12, and preheat the die barrel 16 and the forming die 17;

[0025] Step 3: After the AZ91D is melted, turn on the ultrasonic generator, place the ultrasonic amplitude rod 7 at 5mm below the liquid surface, the ultrasonic power is 1500W, and the ultrasonic frequen...

Embodiment 2

[0027] Method embodiment 2: a method for preparing an aligned carbon nanotube reinforced aluminum matrix composite material, comprising the following steps:

[0028] Step 1: Wrap the A356 aluminum alloy and multi-walled carbon nanotubes with aluminum foil and put them into the crucible 4 according to the volume fraction of 50:1, lower the punch 10 to press the pad 11, open the pressure reducing valve 1 and the valve 14, and pass it into the pressure tank 3. The protective gas is introduced from the air pipe 9, flows through the infusion pipe 6, and finally is discharged from the exhaust pipe 13;

[0029] Step 2: Open the resistance furnace 2, melt all the A356 aluminum alloy in the crucible 4, open the resistance furnace 12, and preheat the die barrel 16 and the forming die 17;

[0030] Step 3: After the A356 aluminum alloy is melted, turn on the ultrasonic generator, place the ultrasonic amplitude rod 7 at 8mm below the liquid surface, the ultrasonic power is 500W, and the ultr...

Embodiment 3

[0032] Method embodiment 3: a method for preparing oriented carbon nanotube reinforced copper-based composite material, comprising the following steps:

[0033] Step 1: Wrap the copper and single-walled carbon nanotubes with aluminum foil and put them into the crucible 4 according to the volume fraction of 200:1, lower the punch 10 to press the spacer 11, open the pressure reducing valve 1 and the valve 14, and pass it into the pressure tank 3, The protective gas is introduced from the air pipe 9, flows through the infusion pipe 6, and is finally discharged from the exhaust pipe 13;

[0034] Step 2: Open the resistance furnace 2, melt all the A356 aluminum alloy in the crucible 4, open the resistance furnace 12, and preheat the die barrel 16 and the forming die 17;

[0035] Step 3: After the copper is melted, turn on the ultrasonic generator, place the ultrasonic amplitude rod 7 at 5mm below the liquid surface, the ultrasonic power is 2000W, and the ultrasonic frequency is 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com