Device for testing contact stress between tire and road surface based on magnetic manometer heat image

A stress testing, magnetic nanotechnology, applied in measuring devices, measuring forces, instruments, etc., can solve the problems of low accuracy, inability to obtain tire ground marks, inability to test three-way force, etc., and achieve high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

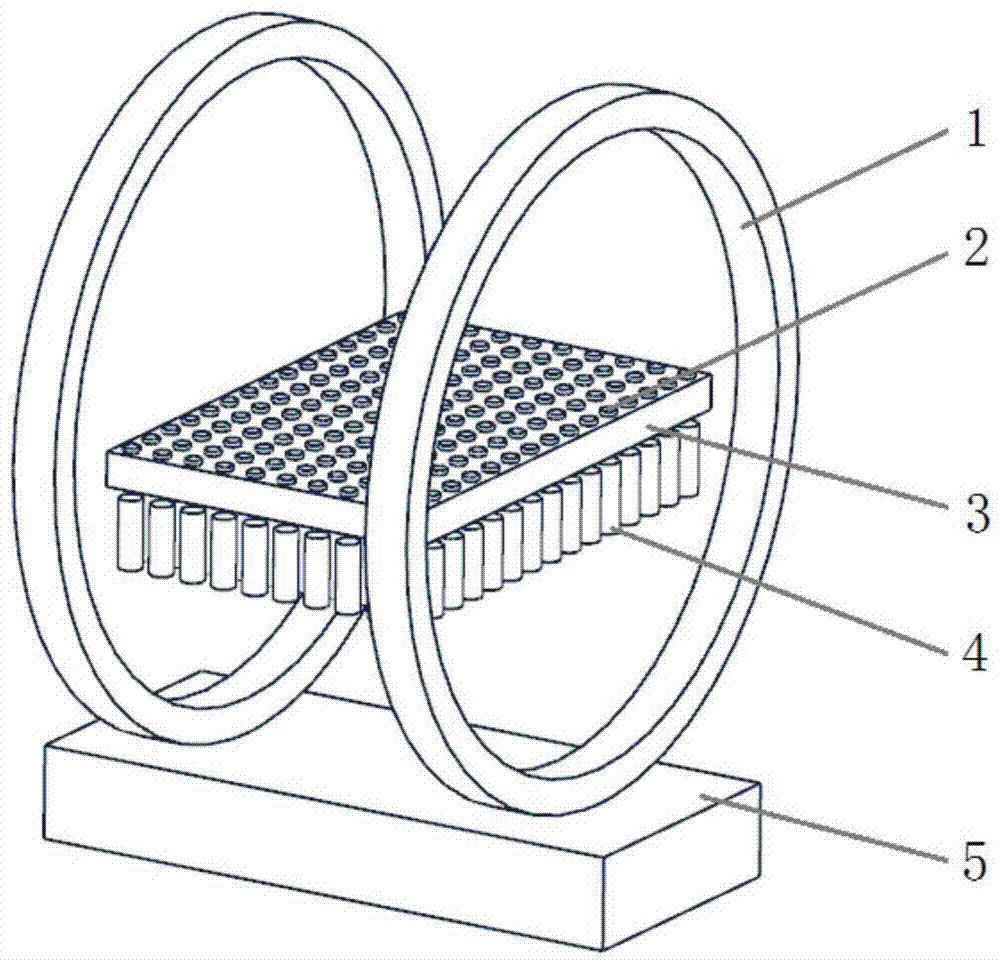

[0032] like figure 1 As shown, the contact stress test device between the tire and the road surface based on the magnetic nano-thermal image implemented according to the present invention includes a stress induction plate 3, an external magnetic field excitation system, and an induced magnetic field test system.

[0033] The stress induction plate 3 is a uniform rectangular thin plate made of non-ferromagnetic metal material; it is characterized in that a superparamagnetic magnetic nanoparticle layer 2 is provided on the upper surface of the stress induction plate 3; the external magnetic field excitation system consists of two vertical The coaxial circular Helmholtz coil 1 arranged at intervals in parallel directions and the control circuit system matched with the Helmholtz coil 1 are composed of two Helmholtz coils 1 vertically arranged on the support base 5 and two The distance between the Holtz coils 1 is equal to the radius of the respective coils; the stress induction pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com