Stress induction in 3D device channel using elastic relaxation of high stress material

a stress induction and high stress technology, applied in the field ofsemiconductor devices, can solve the problems of large challenges for the use of traditional external stressors in channel materials, no clear equivalent solution for compressive stress, and the failure of sige layers to be very defectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

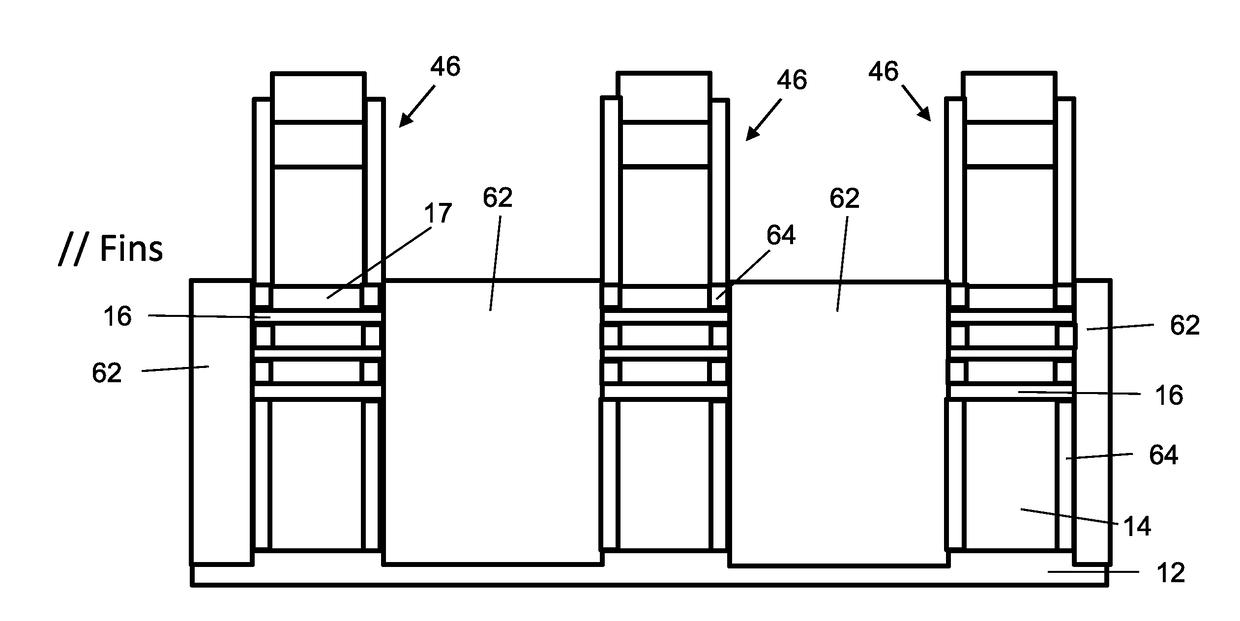

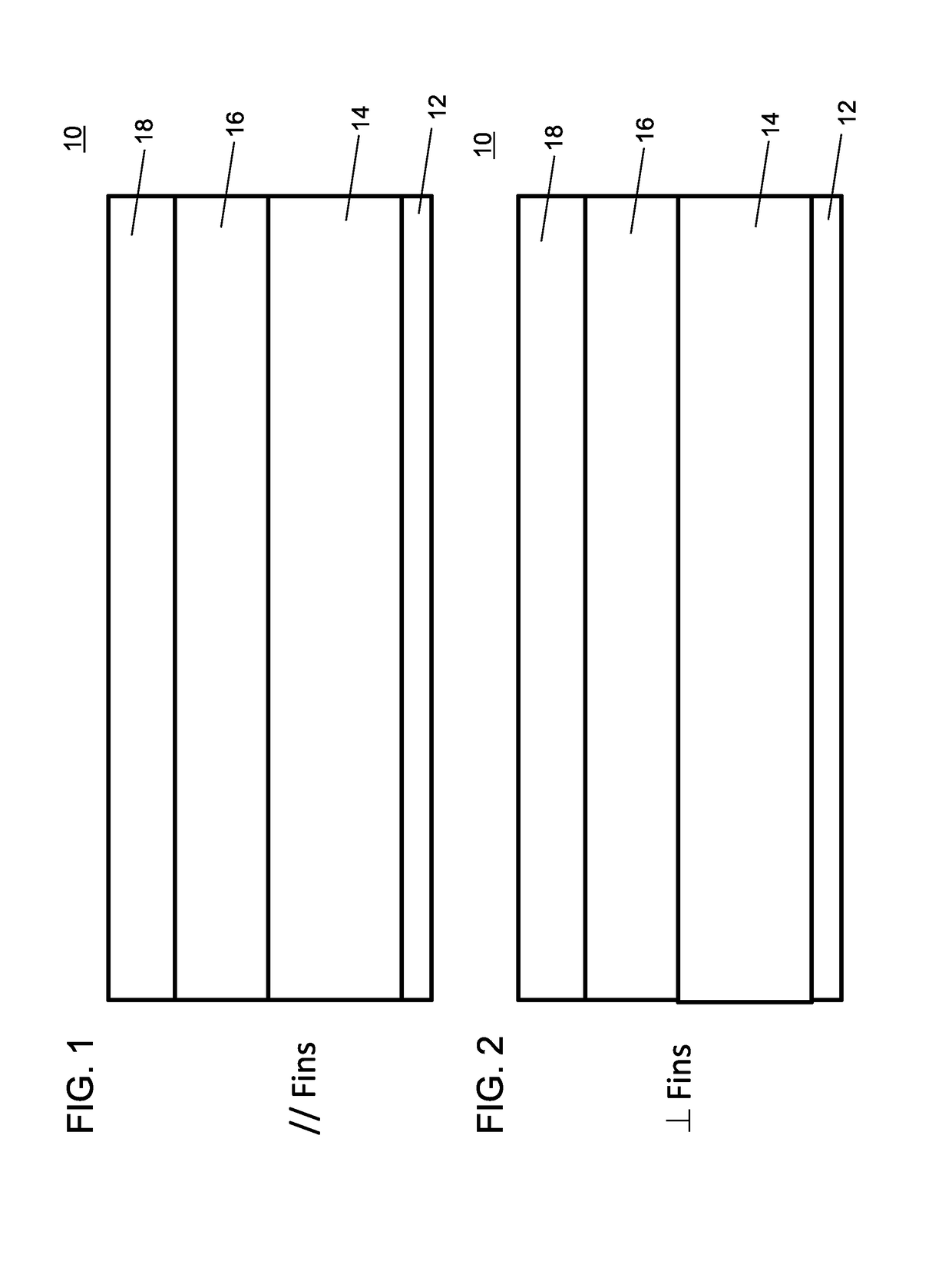

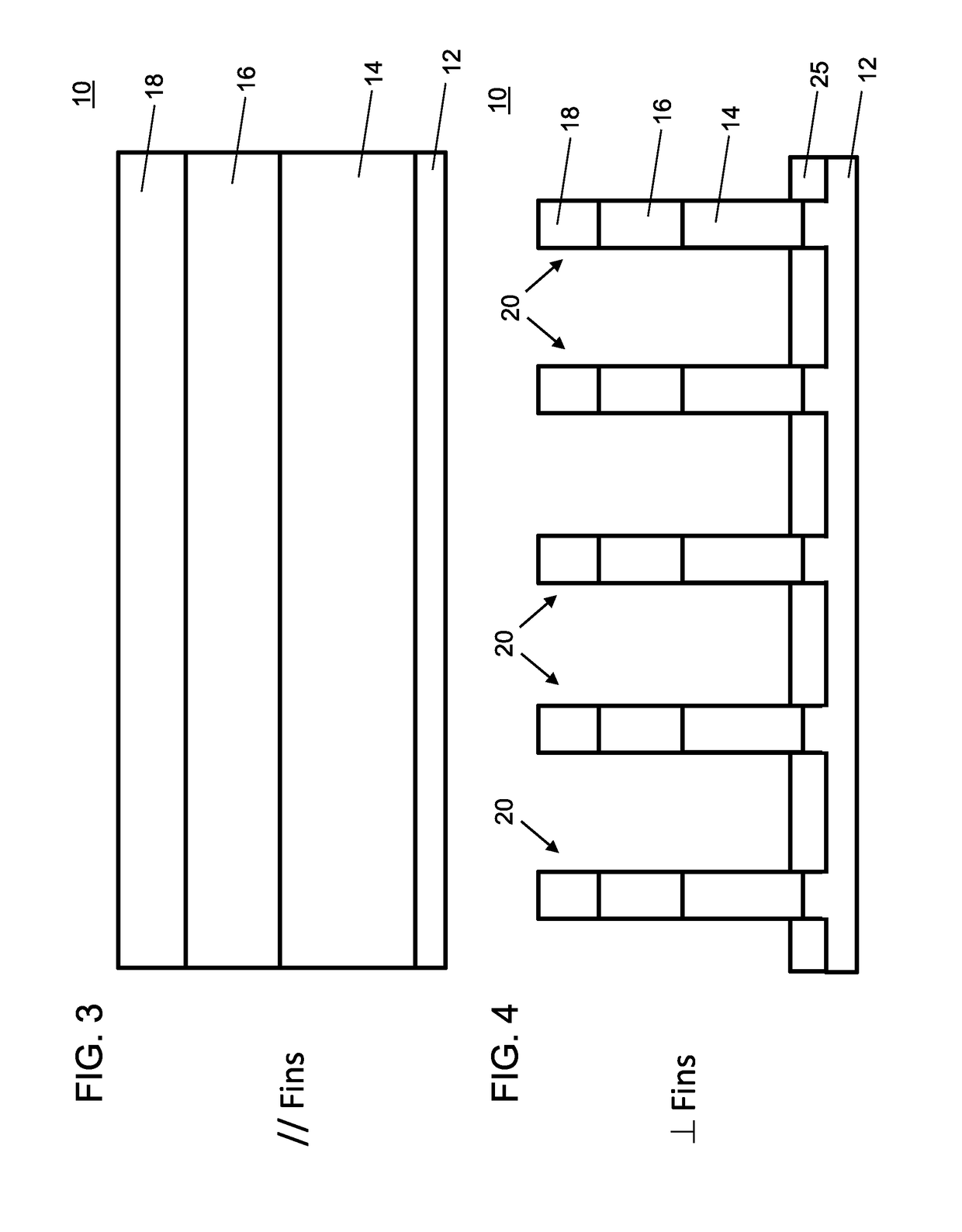

[0036]In accordance with aspects of the present invention, methods and structures are provided to form compressively strained structures. In some embodiments, one or more semiconductor layers or fin structures are rendered compressive. In one example, compressive properties can be applied to a semiconductor layer when a compound is inserted into a lattice of the semiconductor material to alter a lattice constant of the semiconductor material. The compound can include a material that is a crystalline compound and is preferably chemically bound with the material of the lattice. The compound can thus form a semiconductor crystal within a semiconductor matrix and affect the lattice constant of the overall layer.

[0037]In one embodiment, a tensily strained layer can be formed on a substrate to induce tension in an adjacent layer (e.g., device channel). The tensily strained layer may include Si3P4 on Si or SiC on Si, although other material combinations may be employed. The tensily straine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| stress | aaaaa | aaaaa |

| crystal lattice | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com