Electronic skin and preparation method and application thereof

An electronic skin and electrode technology, applied in the field of electronic skin and its preparation, can solve the problems of inability to meet the environmental requirements of electronic skin products, inability to withstand high temperature, low temperature natural environment, time-consuming and inability to semiconductor processes, etc., and achieve easy industrialization The effect of promotion, light weight and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

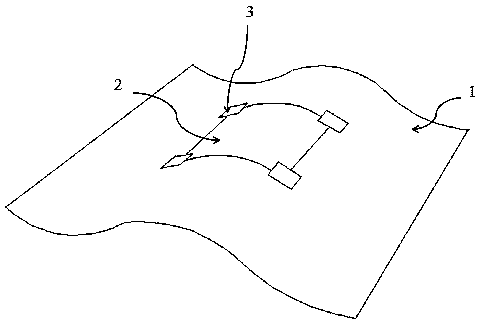

[0050] An electronic skin, such as figure 1 As shown, including mica substrate 1, 50% Nb-doped BaTiO covered on the mica substrate 3 The semiconductor film layer 2, the platinum electrode 3 covered on the semiconductor film layer, the thickness of the mica substrate is 0.5 μm, the thickness of the semiconductor film layer is 10nm, the thickness of the platinum electrode is 30nm, and the surface of the semiconductor film layer is atomically flat surface.

[0051] The preparation method of electronic skin comprises the following steps:

[0052] S1.50% Nb doped BaTiO 3 Preparation of thin film: with Ba 0.5 Nb 0.5 TiO 3 As a target, bombard Ba 0.5 Nb 0.5 TiO 3 The target makes the surface of the formed plasma-deposited mica substrate form Ba 0.5 Nb 0.5 TiO 3 Thin film, deposition conditions: 650°C, oxygen pressure 3.0×10 -4 Pa, laser energy flux density 1.5J cm -2 , the pulse frequency is 1Hz, and the distance between the target and the mica substrate is 45mm;

[005...

Embodiment 2

[0064] An electronic skin, such as figure 1 As shown, including mica substrate 1, 50% Nb-doped BaTiO covered on the mica substrate 3 The semiconductor film layer 2, the platinum electrode 3 covered on the semiconductor film layer, the thickness of the mica substrate is 4.5 μm, the thickness of the semiconductor film layer is 100nm, the thickness of the platinum electrode is 80nm, and the surface of the semiconductor film layer is atomically flat surface.

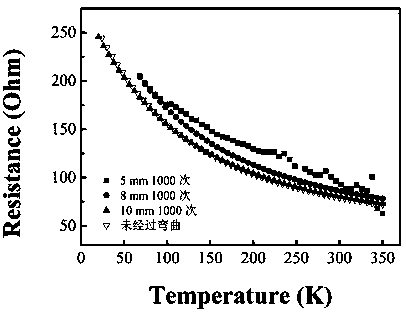

[0065] Its electrical properties are maintained at a low temperature of 20K for 10 hours without significant change, and its electrical properties can still be kept stable after being bent 8,000 times in an atmospheric environment.

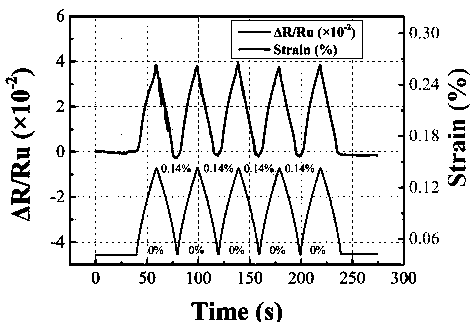

[0066] The stress sensing of the electronic skin is highly sensitive GF30.0. After 8000 bending-flattening cycles, the electrical resistance of the electronic skin still has no significant drift. The electronic skin has good recoverability. According to the test, the resistance of the electron...

Embodiment 3

[0068] An electronic skin, such as figure 1 As shown, including mica substrate 1, 50% Nb-doped BaTiO covered on the mica substrate 3 Semiconductor film layer 2, platinum electrode 3 covered on the semiconductor film layer, the thickness of the mica substrate is 20 μm, the thickness of the semiconductor film layer is 100 nm, the thickness of the platinum electrode is 80 nm, and the surface of the semiconductor film layer is an atomic agent flat surface .

[0069] Its electrical properties are maintained at a low temperature of 20K for 10 hours without significant change, and its electrical properties can still be kept stable after being bent 7,000 times in an atmospheric environment.

[0070] The stress sensing of the electronic skin is highly sensitive GF27.5. After 7000 bending-flattening cycles, the resistance of the electronic skin still has no significant drift. The electronic skin has good recoverability. According to the test, the resistance of the electronic skin rema...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com