Calibration method for indention load-depth curve of micro-bridge of micro-electro-mechanical system

A micro-electro-mechanical system and calibration method technology, which is applied in the direction of strength characteristics, test material hardness, and measurement devices, can solve the impact of unloading initial point contact stiffness, and can simultaneously test micro-bridge structures, Young's modulus, and hardness calculations. Error and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

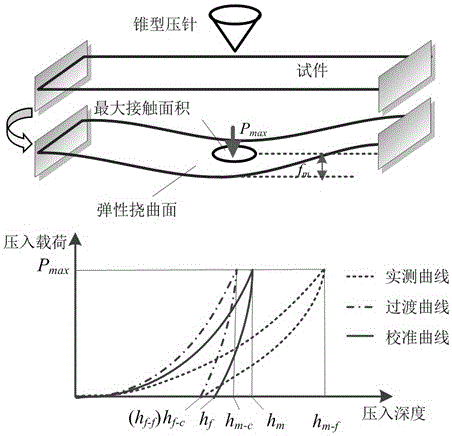

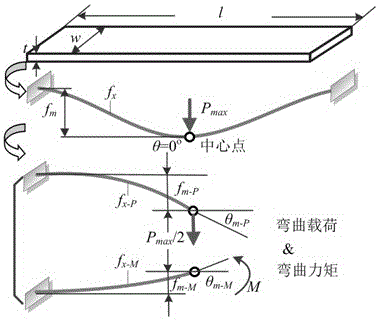

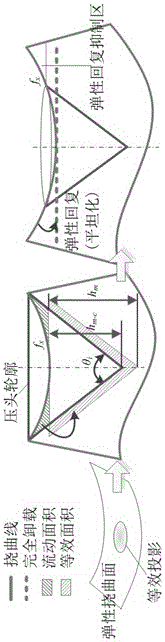

[0028] see Figure 1 to Figure 3 As shown, based on the classic Oliver-Pharr test method and the provisions of ISO14577-1 "Metal Material Hardness and Material Parameter Measurement and Confirmation Test-Part 1: Test Method", when obtaining the indentation load-depth loading and unloading curve (P-h curve ), by obtaining the fitting curve of the maximum indentation depth, residual indentation depth and unloading curve, the parameters such as contact stiffness, hardness and Young's modulus were quantitatively calculated. For the calculation of the contact stiffness S, the unloaded part of the load-depth curve is usually fitted by the least square method as:

[0029] P=α(h-h f ) m (1)

[0030] In the formula, α and m are the fitting parameters related to the tested material, h and h f are the real-time indentation depth and residual depth under the condition of elastic semi-infinite space, respectively. According to the test results of Oliver and Pharr, the value of gain c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com